Sulphur + Sulphuric Acid 2020

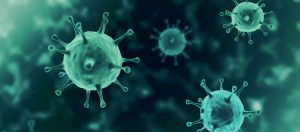

The coronavirus outbreak necessitated a ‘virtual’ CRU Sulphur + Sulphuric Acid conference last year, held in November 2020.

The coronavirus outbreak necessitated a ‘virtual’ CRU Sulphur + Sulphuric Acid conference last year, held in November 2020.

Norilsk Nickel has finally closed down its nickel smelting operation at Nikel in Russia’s Murmansk region; the company’s oldest still operating production facility. The shutdown is part of the company’s environmental programme, which aims to significantly reduce its environmental impact at all production sites. The Nikel closure will eliminate SO2 emissions in the cross-border area with Norway, which had become a major bone of contention with the Norwegian government. Norilsk aims to reduce SO2 emissions at Kola by 50% by the end of 2020 and 85% by the end of 2021, and is modernising its production in Monchegorsk, including the construction of new state-of-the-art facilities.

Process and simulation models can be valuable tools when troubleshooting to solve operational issues in sulphur recovery units. Two examples are provided. In the first case study it is shown how a tuned model was useful in troubleshooting an SRU that was experiencing lower than expected recovery efficiency and apparent channelling in the first catalytic converter. In the second case study an SRU simulation tool is used to investigate sulphidic corrosion in a waste heat boiler.

The turning of a new calendar year is a predictable waypoint in our lives. That is why it has always traditionally been a time for reflection on the past and looking to the future. Therefore, given how 2020 had turned out, perhaps there was an inevitable hope that the turning of the New Year and the start of 2021 might see an improvement in things in general, and of course the trajectory of the pandemic in particular, especially now that several vaccines have been approved for use in record time, and a massive programme of vaccination has begun across the world.

A look back at some of the major events of 2020 for the sulphur and sulphuric acid industries, as well as a look forward as to how 2021 might look.

Demand for oil in developed countries was already falling before the coronavirus outbreak, and consumption growth is slowing in the developing world. Peak oil demand may arrive in the next decade. Coupled with more reinjection of sour gas rather than sulphur extraction, could we be seeing falling elemental sulphur production in a decade or so?

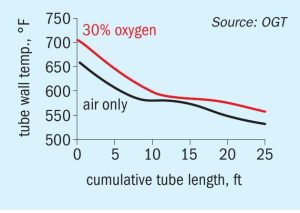

New approaches and novel processing schemes employing oxygen enrichment in sulphur recovery units have been developed and commercialised. In this feature Siirtec Nigi, Linde, Blasch, Fluor and RATE report on their latest developments.

A. Bhargav and A. Krishnan of Helium Consulting Pvt. Ltd discuss how it is possible to reduce SOx emissions within the existing system setup of an oil refinery or gas plant through detailed analysis, expedited corrective actions and the use of automated algorithms in real-time, by using a digital IIoT solution to monitor, control and optimise.

Do you remember Peak Oil? This was the theory, driven by research originally conducted by petroleum geologist M.K. Hubbert in the 1950s, that oil production inevitably followed a bell curve, with supply eventually peaking as easier reserves were exhausted, leading to an inflexion point in production and a long tailing off. Originally Hubbert was talking solely about US oil production, and he seemed to have been borne out by the evidence. But a lack of discoveries of new large fields in the 1990s led to a revision of the theory that predicted a global production peak in 2005-6, potentially leading to rapidly rising oil prices until demand destruction occurred.

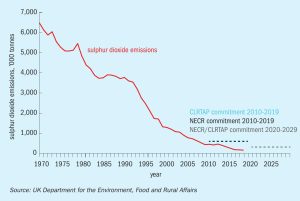

Legislation to control emissions of sulphur dioxide continues to tighten, via vehicle exhausts, and refinery and smelter emissions, leading to increased recovery of both sulphur and sulphur dioxide.