Sulphur fertilizers – the processes, the products

UreaKnowHow.com reviews the main production options for incorporating sulphur into urea, the world's most widely applied commodity fertilizer.

UreaKnowHow.com reviews the main production options for incorporating sulphur into urea, the world's most widely applied commodity fertilizer.

AMETEK Process Instruments has collaborated with Worley Comprimo, part of Worley’s Technology Solutions, to provide sulphur recovery unit (SRU) stakeholders with critical analytical measurements combined with advanced burner control technology to deliver enhanced automated air control management. The companies say that their 2ACT™ Solution is a fully automated system that minimises SRU upsets, enhances reliability, and delivers strong returns on investment. At the heart of this partnership, the innovative 2ACT™ Solution offers an all-in-one approach to advanced air control – significantly boosting SRU performance and efficiency while reducing operational costs. 2ACT uses AMETEK’s IPS-4 ultraviolet and infrared analyser to measure H2 S, CO2 , NH3 , H2 O and total hydrocarbons (THCs) by continuously sampling the acid gas upstream of the SRU. The change in air demand requirement is then calculated, with main and trim air adjustments implemented automatically by the feed forward control scheme designed by Worley Comprimo. The companies say that the benefits of the 2ACT Solution include maintaining an optimal H2S to SO2 ratio at the outlet of the Claus Plant to maximise recovery efficiency, mitigating damage to tail gas treatment unit (TGTU) components, lowering SO2 emissions and carbon footprint with improved uptime and plant throughput.

Topsoe has been selected by Zhongneng Yida New Energy Co., Ltd to deliver technology for production of sustainable aviation fuels (SAF) at a new facility to be located at the city of Shijazhuang in the Shenze Economy Development Zone of Hebei province. Zhongneng Yida plans to export the produced SAF to European and local Chinese markets. Topsoe will provide its HydroFlex® technology and catalysts as part of the agreement. The facility will produce 400,000 t/a of SAF, utilising used cooking oil for the feedstock.

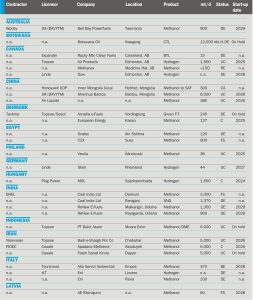

A round-up of current and proposed projects involving non-nitrogen synthesis gas derivatives, including methanol, synthetic/substitute natural gas (SNG) and gas- and coal to liquids (GTL/CTL) plants.

Granulation offers a scalable and reliable way of recovering crop nutrients from waste, says Nick Reckinger of FEECO International.

Arkema's John Suldickas, Heather McKay and Juan Gonzalez Leon explore innovations in fertilizer dust control.

Fertiberia’s Cinta Cazador Ruiz outlines the aims of the B-FERST project and highlights its major successes.

EasyMining’s Christian Kabbe provides an update on the company’s first full-scale Ash2™Phos plant in Germany.

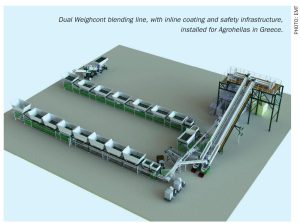

Zico Zeeman, EMT’s Commercial Director, highlights two notable high-performance fertilizer blending projects.

Fertilizer International interviews Joe Brady, Pursell's Chief Financial Officer, ahead of the Southwestern Fertilizer Conference in Nashville in mid-July.