Battery materials driving sulphur consumption growth

In this CRU Insight, Peter Harrisson reports on how battery materials have become a powerful driver of sulphur consumption growth.

In this CRU Insight, Peter Harrisson reports on how battery materials have become a powerful driver of sulphur consumption growth.

CS Combustion Solutions introduces the SR-P sulphur atomiser nozzle to the sulphuric acid process, combining the high-quality atomisation of ultrasonic systems with the affordability and simplicity of pressure atomisers.

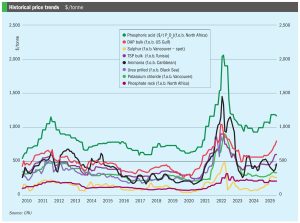

Price trends and market outlook, 21st August 2025

Sulvaris is aiming to transform low-value by-products into high-performance, field-ready premium nutrient products.

SulGas® KL 2025 - 17 speakers, dedicated exhibition area, panel discussions...

Although elemental sulphur is relatively non-toxic, it presents significant risks when stored or transported. DuBois Chemicals Canada highlights advancements in both dust suppression and acidity control, including the development of novel agents designed specifically for use with elemental sulphur.

UreaKnowHow.com reviews the main production options for incorporating sulphur into urea, the world's most widely applied commodity fertilizer.

India India has imposed five-year anti-dumping duties on six Chinese imports, including insoluble sulphur, mainly used in the vulcanisation of rubber. The move follows an investigation by India’s Directorate General of Trade Remedies (DGTR) last year, following a complaint by Oriental Carbon and Chemicals in March 2024. The period covered by the investigation was from 1st Jan 2023 to 31st Dec 2023, while the injury investigation period ran from April 2020 to 31st Dec 2023. DGTR made a determination that Chinese exporters had been selling the six products at unfairly low prices, adversely affecting the profitability of Indian producers. DGTR says that the duties it has imposed are “aligned with WTO norms” and aim to protect domestic industries from unfair trade practices and address the growing trade imbalance with China. According to the trade authority, the market share of the countries subject to duties “has been significantly increasing” while local Indian industry’s capacities are “lying idle” amid growing demand. n

New sulphur production from Chinese and Indian refineries and Middle Eastern sour gas and the ramp up of nickel leaching projects in Indonesia continue to change the direction of sulphur trade.

The progressive closure of smelter capacity in Australia poses potential problems for acid consumers across the country.