Ammonia and sulphur market trends

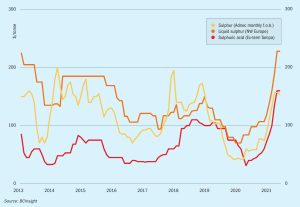

Ammonia and sulphur, as essential raw materials, underpin and drive fertilizer production costs. A steep and sustained rally has seen prices for both commodities reach new heights in recent months.

Ammonia and sulphur, as essential raw materials, underpin and drive fertilizer production costs. A steep and sustained rally has seen prices for both commodities reach new heights in recent months.

Market Insight courtesy of Argus Media

Preliminary engineering work has started on a renewable powerto-fertilizer plant in Kenya.

Polysulphate is an affordable, easy-to-use, multi-nutrient fertilizer with a low environmental impact. ICL’s chief agronomist, Patricia Imas, highlights the crop benefits of this natural and high-value product.

A selection of innovative products and technologies that have recently been brought to market.

Metal dusting corrosion damage on steam reformers is no longer a major issue in modern methane steam reformer units. Nevertheless, failures related to metal dusting corrosion attack still take place in some specific designs and configurations that are more prone to experience this damage. Poor maintenance or deterioration of insulation components on transition areas might expose metallic surfaces to metal dusting attack. In this article, Dr P. Cardín and P. Imízcoz of Schmidt+Clemens Group describe different case studies, where the end users benefited from the experience of a collaboration to address potential risks and improve plant reliability against metal dusting corrosion damage.

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

The Abu Dhabi National Oil Company (ADNOC) has awarded a $510 million engineering, procurement and construction (EPC) contract to Italy’s Saipem to expand production capacity at the Shah sour gas plant, as the UAE looks to increase its output of gas by 2030. The Optimum Shah Gas Expansion (OSGE) & Gas Gathering project has been awarded by ADNOC Sour Gas, a joint venture between ADNOC and US energy major Occidental. The contract will increase gas processing capacity at the Shah plant by 13% per cent to 1.45 bcf/d from 1.28 bcf/d by 2023 and supports ADNOC’s objective of enabling gas self-sufficiency for the UAE. The Shah gas plant currently meets 12% of the UAE’s total supply of natural gas, as well as producing 5% of the world’s elemental sulphur. The expansion will cumulatively represent a 45% increase on the plant’s original capacity of 1.0 bcf/d when it came on-stream in 2015.

Sulphur ’s annual listing of new or recently completed sulphur forming projects worldwide covers both new sour gas and refinery sulphur forming projects as well as upgrades at existing units.

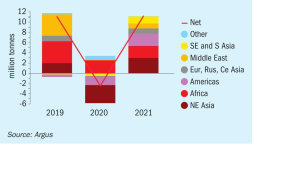

Significant capacity additions in the Middle East are still awaited. The more positive outlook for fuel demand is providing support to seeing these projects ramp up in the coming months. New supply is expected from Saudi Arabia following the commissioning of a gas project in 2020, sulphur availability is likely to improve from the country through the second half of 2021 and into 2022 as a result.