Sulphur dust suppression

Sulphur dust is one of the greatest hazards when producing and handling solid sulphur, and methods for its suppression are vitally important to prevent fire and explosion.

Sulphur dust is one of the greatest hazards when producing and handling solid sulphur, and methods for its suppression are vitally important to prevent fire and explosion.

Kazakhstan’s oil and condensate output increased by 7% from 1.79 million bbl/d to 1.92 million bbl/d in early June after sour gas reinjection operations resumed at the Kashagan offshore oil and gas development following a recent outage, according to the Kazkah Energy Ministry. Reinjection of sour gas into two wells resumed on 8th June, enabling operator the North Caspian Operating Company (NCOC) to boost oil and condensate production at a large artificial island in Kazakhstan’s Caspian Sea waters. Reinjection was paused on May 20th following the detection of sour gas during routine sampling and a subsequent integrity test. Kashagan normally produces about 300,000 barrels of oil per day. Kazakhstan expects Kashsgan to raise oil production this year to 18.2 million t/a from 12.7 million t/a in 2022.

Abdulrahman Al-Fageeh is the new CEO of SABIC. He is also the current chairman of SABIC Agri-Nutrients, the company’s fertilizer division.

Bedeschi has been awarded a contract by Tecnicas Reunidas and Wison Engineering for the engineering and supply of new sulphur-handling equipment. Tecnicas Reunidas and Wison Engineering are working in a 70-30 joint venture partnership on the North Field Expansion Project (NFXP) Sulphur Project, which forms part of the overall Qatar North Field Expansion Project. Last year were awarded a $600 million contract to process and export sulphur from the projected expansion of the liquefied natural gas (LNG) facilities in Ras Laffan Industrial City. The new sulphur plant will have the capacity to process an average of 5,000 t/d of molten sulphur.

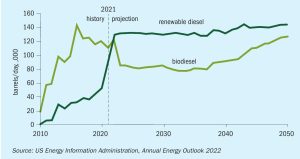

The production of renewable fuels by retrofitting existing refineries and their infrastructure is witnessing exponential growth. The impact on the existing amine, sour water and sulphur recovery units is inevitable. Based on several case studies, Worley Comprimo discusses the various options available to holistically review the sulphur block to determine the impact and mitigation of processing bio-feed.

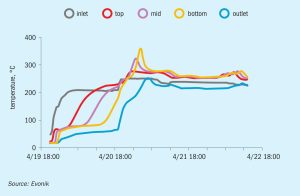

Evonik explores the development of catalyst reuse and how recycled hydroprocessing catalysts can be successfully applied in tail gas treating units to deliver cost and performance gains.

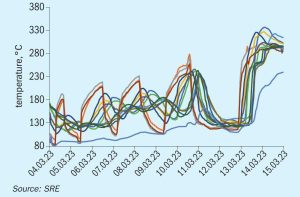

Sulfur Recovery Engineering shares the lessons learned from an emergency shutdown of an MCRC sulphur recovery unit in the middle of a cold Canadian winter.

SulGas, South Asia’s sulphur recovery and gas treating conference, returned to a live event in 2023, providing participants with a platform to interact with experts in the field, share best practices and troubleshooting tips with fellow refiners and discuss advanced technologies and operating procedures with technology providers, vendors and licensors.

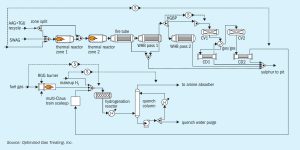

SO2 breakthroughs remain an ever present threat to the successful operation of reductive, quenchamine-based tail gas clean-up units (TGUs). Optimized Gas Treating presents a case study which demonstrates how SulphurPro's detailed reaction kinetics and mass transfer rate model can be used to analyse integration techniques and mitigation methods.

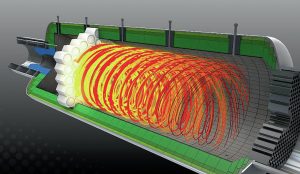

Blasch Precision Ceramics reports on the deployment of VectorWalls™ to improve the performance of the SRU thermal incinerator and provide benefits such as lower fuel gas consumption and lower CO2 emissions.