SRU energy and cost optimisation

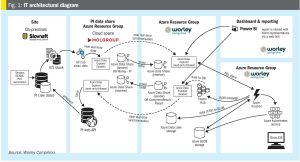

Together with Slovnaft, Worley Comprimo has developed a near real-time monitoring dashboard using data sharing via the Cloud. Using a two-year data set containing minute average data, trends and insights were used to optimise performance. This paper describes the main learnings and improvements with respect to energy optimisation, which supports sustainability targets for Slovnaft.