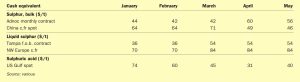

Price Trends

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

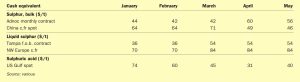

The removal of hydrogen sulphide (H2 S) has become increasingly important as the oil and gas industry moves towards more efficient and sustainable production of lower emission clean fuels. BASF and ExxonMobil* have jointly developed a proprietary amine, OASE® sulfexx™ , to help refiners and gas processors achieve sulphur removal targets while reducing their carbon footprint via lower energy consumption. This new solvent technology is suitable for low and high pressure applications and shows superior performance characteristics over generic and promoted MDEA formulations, as well as sterically hindered amines such as FLEXSORB™ SE and SE Plus.

Sulphur demand losses for production of phosphoric acid are forecast at 2.2 million t/a in 2020. Factoring in demand gains in markets such as Morocco, the sector is expected to see a drop of 800,000 t/a in 2020. Recovery is forecast from 2021 with a 2 million t/a increase forecast.

There was a rapid increase in sulphuric acid demand for copper, uranium and nickel leaching from 1995-2015, but over the past few years growth in this sector has slowed dramatically. Now however there are signs that demand is starting to pick up again with several new projects under development.

Kreber’s R&D department has been researching the prilling of sulphur in pursuit of the ideal process. In this article, T. Nieboer of Kreber recounts the history of prilling up to today, tracing the developments and highlighting the challenges that still remain.

Sulphur demand in Australia has been boosted by the restart of the nickel leaching plant at Ravensthorpe, and new HPAL projects are under development, but a slew of new phosphate projects are not scheduled to consume more acid domestically.

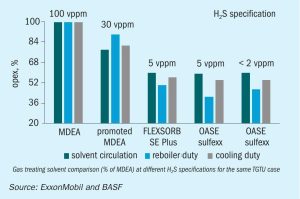

With increasing frequency, companies that have molten sulphur on site must put environmental controls on the vent streams from molten sulphur pits, storage tanks and loading operations. This article* describes the typical characteristics of molten sulphur vent gas streams as well as some of the important chemistry related to these systems in caustic scrubbers. Solids deposition issues observed in the field with caustic scrubbers operating on actual molten sulphur vent gas streams are presented. Design and operational strategies to mitigate plugging in molten sulphur vent gas scrubbers are also summarised in this article by D. J. Sachde, K. E. McIntush, D. L. Mamrosh , and C. M. Beitler of Trimeric Corporation.

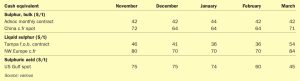

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

How the macro market responds to the coronavirus pandemic over the months ahead and governmental response in different parts of the globe will likely have a lasting impact on the outlook for the sulphur market.

A look at the major factors influencing the sulphur market around the world.