Ammonia plant hybridisation

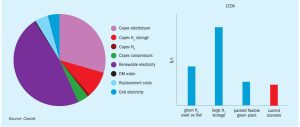

Casale presents different scenarios based on energy availability for the integration of an existing ammonia facility with green hydrogen to supplement or replace the grey ammonia production with green ammonia.

Casale presents different scenarios based on energy availability for the integration of an existing ammonia facility with green hydrogen to supplement or replace the grey ammonia production with green ammonia.

With the current focus on decarbonising ammonia production, Johnson Matthey explains the important role of high activity ammonia synthesis catalyst in the production of green ammonia.

Distributed and carbon-free ammonia production with Stami Green Ammonia technology offers a highly competitive alternative to conventional grey processes, paving the way for scaling up and sustaining local communities with renewable energy sources.

PT Petrokimia Gresik detail an inventive redesign of their economiser, a critical component in sulphuric acid production, focusing on energy efficiency, decarbonisation, process optimisation, and equipment durability.

Low carbon production is attracting considerable attention to using syngas derivatives as fuels, but there are considerable logistical and commercial barriers to overcome.

Sustainable aviation fuel (SAF) is increasingly seen as a vital tool in the aviation sector’s transition to net zero. These drop-in fuels, which can be derived from bio and renewable-derived syngas, are used to dilute the fossil-derived components of fuel and are fully compatible with existing fuel infrastructure. This positions SAF as a convenient and rapid route towards decarbonisation. However, questions remain around its ultimate viability at scale and whether it really can be the ‘silver bullet’ aviation leaders are looking for. We spoke to Paul Ticehurst from Johnson Matthey (JM) to shed some light on SAF and the future role of syngas in aviation.

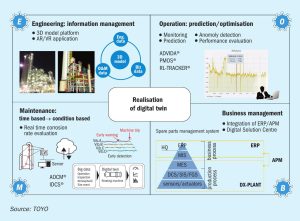

TOYO’s digital twin concept combines its unique digital twin at both the project execution stage and the commissioning stage, and when used in conjunction with its proprietary process simulator it can predict the whole plant lifecycle.

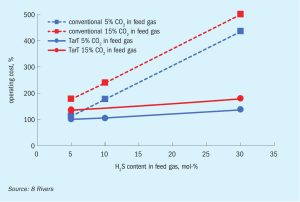

TarT technology, one of 8 Rivers’ decarbonisation technologies, shows promise as an economical, efficient, sour gas sweetening process with near-zero carbon dioxide emissions, and may be key to unlocking access to the world’s sour gas reserves.

Antoine Hoxha, the new Director General of Fertilizers Europe, looks ahead at the future of the EU fertilizer industry, setting out his vision of an industry transformed by decarbonisation, new energy markets, sustainable agriculture and the circular economy.

Hydrocarbon-based production of ammonia carries an unavoidable carbon footprint. But one of the best methods for mitigating that footprint is already here: ultra-low carbon-intensity ammonia production, also known as “blue” ammonia. With blue ammonia production, a typical ammonia plant can sequester or repurpose game-changing volumes of carbon dioxide that would otherwise end up in the atmosphere. To help foster an optimal understanding of the benefits, Ameet Kakoti and Per Juul Dahl of Topsoe A/S provide an overview of the technologies that can help any ammonia operation achieve and maintain sustainable operations – sooner rather than later.