Fertilizer International 530 Jan-Feb 2026

23 January 2026

How best to use enhanced efficiency fertilizers

FERTILZER TECHNOLOGY

How best to use enhanced efficiency fertilizers

From controlled-release to plant-level innovations, fertilizer technology is changing, boosting yields, cutting losses and supporting sustainability. ICL’s strategy focuses on the use of enhanced efficiency fertilizers (EEFs), explains Ronald Clemens, the company’s Global Portfolio Manager.

Eqo.x is the first controlled-release coating technology designed to met the EU’s 2028 biodegradability criteria. PHOTO: ICL

Global food demand is rising, meaning agriculture must boost productivity while reducing input use, emissions, and environmental impact. Meanwhile, stricter legislation is pushing the industry to rethink long-standing fertilizer practises, with growers facing higher expectations than ever before.

ICL is positioning itself at the centre of this transition, advancing a new fertilizer narrative; one that moves beyond volume and formulation, and focuses on efficiency, biology and smarter nutrient management.

“ICL’s approach is to make nutrients worker harder, aligning nutrient release with crop demand, improving uptake inside the plant, and reducing losses to air, soil and water,” says Ronald Clemens, Global Portfolio Manager for controlled-release fertilizer (CRF).

Nitrogen remains the most essential – and problematic – nutrient in agriculture. Despite decades of improvement, nitrogen fertilizers remain highly inefficient. On average, only 40-60% of applied nitrogen

is taken up by crops, with the remainder lost through ammonia volatilisation, nitrate leaching, run-off and denitrification. These losses represent both environmental damage and unnecessary cost.

Across Europe, this inefficiency is no longer tolerated. Policies like the European Commission’s Fit for 55 package aim to cut greenhouse gas emissions by 55% by 2030, reduce nutrient losses by 50%, and lower fertilizer use by around 20%. Yet, despite these regulations, yield expectations remain unchanged.

A toolbox approach

ICL’s strategy centres on enhanced efficiency fertilizers (EEFs), recognising that no single technology can address every cropping system, soil type, or climate. Instead, farmers are encouraged to adopt a ‘toolbox’ approach, combining technologies to manage different nitrogen loss pathways.

Stabilised nitrogen fertilizers use urease and nitrification inhibitors to slow nitrogen transformations in the soil, reducing volatilisation, leaching and nitrous oxide emissions. CRFs by contrast, physically isolate nutrients within a membrane, releasing them gradually as moisture penetrates the coating and osmotic pressure drives diffusion.

“By using a membrane around the granule, you can clearly improve efficiency,” explains Ronald. “Nutrients that the crop cannot take up are not lost to the environment.”

CRFs are particularly valuable in longer-cycle crops including maize, rice, potatoes, onions and forestry, where they reduce application frequency while maintaining yield.

The performance data behind CRFs is robust. A meta-analysis of 21 studies conducted by Australian researchers showed CRFs decreased nitrogen losses in all pathways – by up to 80% – compared with conventional urea. Field trials across Europe consistently confirm these findings, demonstrating improved uptake, reduced nitrogen losses and stable or increased yields across cereals, root crops and vegetables.

Biodegradable coatings

Upcoming legislation is also reshaping CRF design. From October 2028, CRFs placed on the EU market will need to be rapidly biodegradable in soil and water, addressing concerns over long-term polymer accumulation.

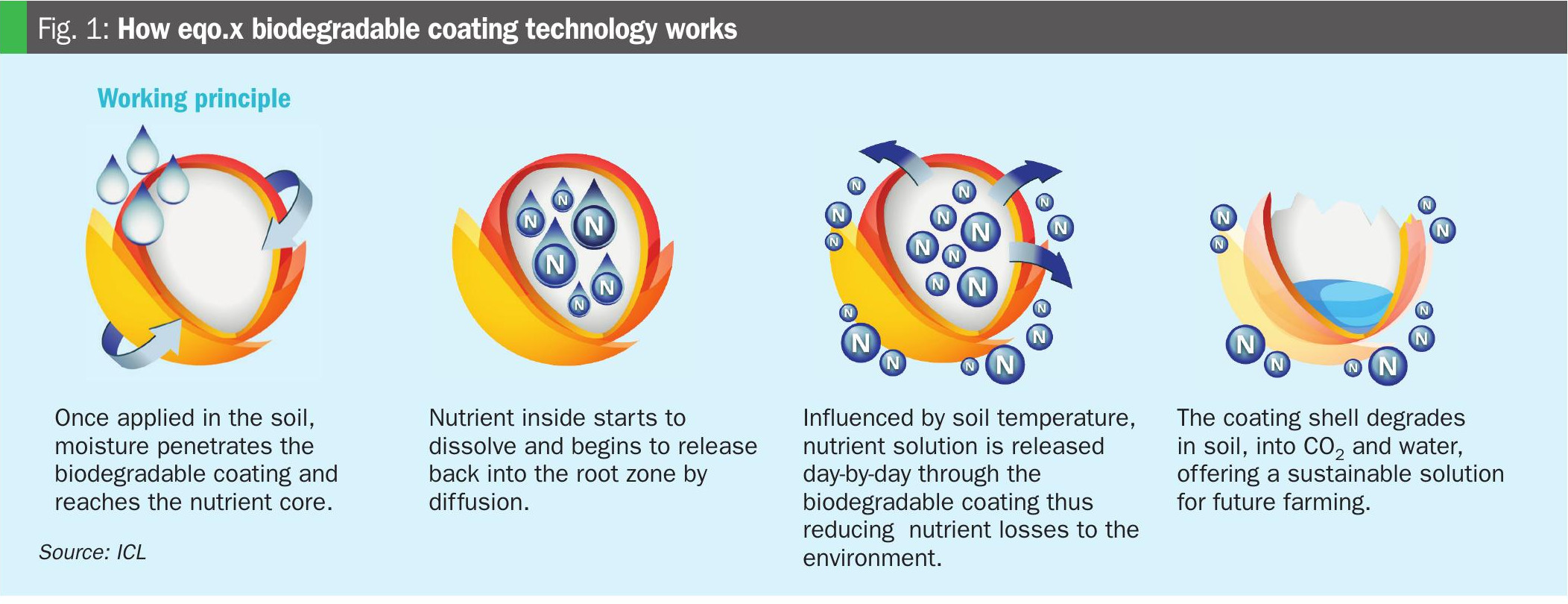

In response, ICL is developing coating technologies that combine nutrient release with full biodegradability. Eqo.x is the first controlled-release coating technology (Figure 1) on the market designed to meet the EU’s 2028 biodegradability criteria – four years ahead of regulation (Fertilizer International 510, p24; Fertilizer International 522, p24). This new approach integrates sulphur with biodegradable coating materials that maintain controlled nutrient release before breaking down naturally in the environment.

“Biodegradability is assessed through standardised tests,” says Ronald. “Once certified these coatings set a new benchmark for sustainable nutrient delivery – and Eqo.x is the first to achieve this in the EU.”

Cutting carbon

By reducing nitrogen losses and the number of applications required, CRFs can significantly lower field-level emissions. Field trials across Europe show that CRFs can reduce nitrogen leaching by up to 55%, while cutting greenhouse gas emissions.

In cereal systems, these efficiencies have translated into savings of up to 56kg CO2 -equivalent per tonne of grain, while potato systems have recorded reductions of 18kg CO2 -equivalent per hectare. As carbon reporting extends further down agricultural supply chains, such verified reductions are increasingly linked to sustainability premiums and emerging carbon credit schemes for growers.

Targeting innovation from all angles

ICL strives to create innovative nutrient solutions in its full product portfolio to make nutrient uptake more efficient in all possible ways. Innovation is also extending beyond macronutrients into biodegradable chelates and biostimulant science, challenging how micronutrients are delivered and how plants respond to stress.

Traditional chelates (which bond with micronutrients to keep them available to the plant) like ethylenediaminetetraacetic acid (EDTA) are effective but persistent. In many formulations, only around 15% of the product is nutrient, with the remainder consisting of synthetic material that offers no biological benefit and can accumulate in soils and waterways.

ICL has also developed new biodegradable chelates based on peptide structures and organic acids, which are designed to overcome these limitations. These molecules act as nutrient carriers and biostimulants, enabling rapid micronutrient uptake and activating plant defence and growth pathways.

Advanced imaging techniques, including synchrotron X-ray imaging, have allowed researchers to track nutrient movement inside living plants. The results showed zinc uptake in as little as 13-17 hours, compared with 26 hours for conventional sulphates, alongside improved remobilisation and stress tolerance. Laboratory tests also showed 100% biodegradation within 22 days, aligning with future regulatory expectations for biodegradable inputs.

Evolving innovation

Taken together, these technologies signal a fundamental shift.

“Fertilisation is no longer just about feeding the soil per applied kilograms, it is about managing plant physiology, soil biology and environmental impact,” sums up Ronald.

“There is no single solution,” he adds. “But by using the right tools, in the right place, at the right time, nutrients can work harder – for crops, for farmers and for the environment.”

Acknowledgement

Additional reporting by Danusia Osiowy, Agri-hub.