Fertilizer Latino Americano welcomes you to Miami!

Argus in collaboration with CRU will convene the 2022 Fertilizer Latino Americano conference in Miami, Florida, 21-23 March.

Argus in collaboration with CRU will convene the 2022 Fertilizer Latino Americano conference in Miami, Florida, 21-23 March.

Ken Seitz has been named as Nutrien’s interim CEO following the resignation of the former CEO and president Mayo Schmidt on the 4th of January. Schmidt had only been in post for eight months, having taken over from Chuck Magro in April 2021. Mr Seitz was the company’s executive vice president and CEO of potash prior to the announcement. His appointment is a transitional arrangement.

Newly developed flotation reagents are improving the selectivity and grade/recovery of phosphate and potash concentrates.

A proper leak detection system for loose liners of high-pressure urea equipment is the number one safeguard for any urea plant, as has been proven by detailed safety studies and incidents investigations. However, leak detection systems easily choke especially when urea is present in the leaking solution. When no urea is present, the ammonium carbamate will dissociate above 60°C when flashing to atmospheric pressure in the leak detection system. But, when urea is present, it can solidify and at higher temperatures polymerise into biuret and triuret, which have even higher crystallisation temperatures. An early and reliable leak detection system is therefore very important. UreaKnowHow.com has developed such a system: the state-of-the-art AMMO LASER Leak Detection System.

Nutrien Ltd has announced that Mayo Schmidt has left his position as president and CEO of Nutrien and has resigned from the Board. Ken Seitz , Executive Vice President and CEO of Potash, has been named the company’s interim CEO. Seitz brings extensive global leadership experience in the agriculture and mining sectors and is well-positioned to progress the company’s stated strategy and lead the integrated business during the transition.

Polysulphate is a new multi-nutrient fertilizer mined in the UK. Its unique characteristics and mix of nutrients make it especially suitable for potato crops, explains Patricia Imas, chief agronomist at ICL Innovative Ag Solutions (IAS).

Topsoe has begun operations at a demonstration plant for the production of methanol from biogas. The aim is to validate the company’s electrified technology for cost-competitive production of sustainable methanol from biogas as well as other products. The project is supported by the EUDP Energy Technology Development and Demonstration Program and is developed together with Aarhus University, Sintex A/S, Blue World Technology, Technical University of Denmark, Energinet A/S, Aalborg University, and Plan-Energi. The demonstration plant is located at Aarhus University’s research facility in Foulum, and will have an annual capacity of 7.9 t/a of CO 2 -neutral methanol from biogas and green power and is scheduled to be fully operational by the beginning of 2022. It uses Topsoe’s eSMR ™ technology, which is CO 2 -neutral when based on biogas as feedstock and green electricity for heating. It also uses half the CO 2 that makes up about 40% of biogas and typically is costly to separate and vent in production of grid quality biogas.

Scanfeld™ is the world’s first remote sensing solution for fully automated early-warning gas leak detection for chemical plants. Using FTIR spectroscopy, Scanfeld™ identifies hundreds of different gases in real time from kilometres away. With just a few Scanfeld™ sensor units, large production sites, tank farms, or gas loading areas can be monitored reliably. Gas leaks are quickly detected, and the formation of dangerous gas clouds is monitored, measured, and visualised. René Braun of Grandperspective discusses how the system works and how it is being applied in industry.

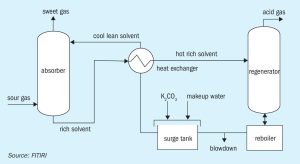

Arun Murugan and Mike Antony of FITIRI and Venkat Pattabathula of SVP Chemical Plant Services discuss the COORS Analytics system for more accurate prediction of the performance of a CO 2 removal system.

MegaZonE™ is a newly introduced layered loading technology for boiling water-cooled reactors used for methanol synthesis. This new concept is one of the latest results of the long-standing collaboration between Air Liquide Engineering & Construction and Clariant Catalysts to improve the methanol process flowsheet and optimise catalyst performance in the complete reactor system.