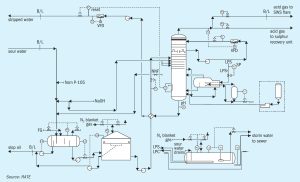

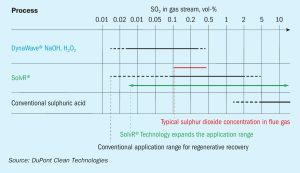

Sour water stripping gas processing options

M. Rameshni and S. Santo of RATE discuss different sour water stripping gas processing options, depending on contaminants in the sour water streams and site-specific requirements.

M. Rameshni and S. Santo of RATE discuss different sour water stripping gas processing options, depending on contaminants in the sour water streams and site-specific requirements.

New low-cost metal oxide solid scavengers for hydrogen sulphide (H2 S) removal from wet and dry natural gas have been developed and deployed at commercial scale. The desulphurisation process uses a proprietary sorbent chemistry to achieve a high sulphur capacity and removal efficiency. G. Alptekin, F. Kugler and M. Schaefer of SulfaTrap LLC describe the new technology and its performance.

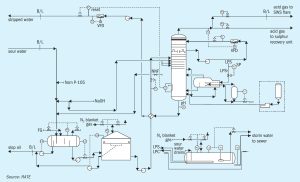

China is the world’s largest importer of sulphur, mainly to feed domestic phosphate production. Sour gas in Sichuan and new refinery production, coupled with rationalisation in the phosphate sector are all leading to reduced imports, while new smelters are increasing sulphuric acid production and reducing the need for pyrite-based and sulphur burning acid production.

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Chemetics describes a variety of ways to extend the life of sulphuric acid plants. Debottlenecking, emissions reduction and/or energy recovery projects require a systematic, phased approach to maximise the potential of economic and operational benefits to the owner.

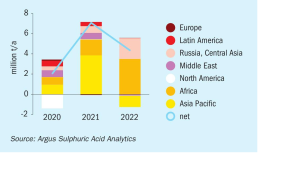

Tightening regulations and growing global competition are increasing the pressure felt by sulphuric acid plant operators to reduce emissions and improve energy output. Conservation of energy is a continuous focus for operators, and environmental communities have grown more vocal in their desire for greater emissions oversight. In this article, DuPont Clean Technologies examines simple, tried, and true tactics, as well as new products and designs that can be incorporated into existing plants to address operating efficiency and emissions and to help to prolong the life of the plant.

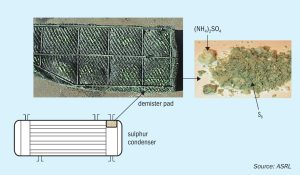

ASRL has conducted studies on ammonia destruction in the sulphur recovery unit (SRU) for over a decade1-5 . Other studies at ASRL have investigated mechanisms for ammonium salt formation and deposition downstream in the Claus plant, as well as the potential sources of ammonia (NH3 )in a gas plant7 . A less understood subject is addressing how much residual NH3 is tolerable or at what temperature will residual NH3 cause ammonium salt deposition. In this study, existing knowledge on thermal stability of ammonium salts and new measurements have been used to identify the gaseous components required for deposition, through reversible vapour pressure expressions.

As well as Morocco, Egypt, Algeria and Tunisia all have major phosphate industries, and all of these countries have plans to expand their capability to extract and process phosphates, though Algeria and Tunisia remain hampered by political instability.

Dealing with sulphur dust is an operational challenge for sulphur forming plants and sulphur storage and handling facilities.

The processed phosphates market view is supporting sulphur demand. The average DAP price for Morocco f.o.b. is forecast to rise significantly on 2020 levels. As the leading end use for sulphur consumption and trade, this has implications for pricing. The expected downward correction in DAP in 2022 will likely lead to a parallel decline in sulphur, at a time when supply is expected to improve in the oil and gas sector, adding further pressure for prices to ease.