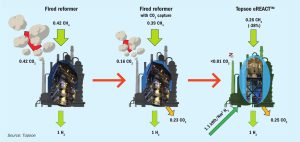

Emissions-free syngas manufacturing

The world’s most common syngas production method remains steam methane reforming, a process which has a substantial CO2 footprint as the necessary reaction heat is supplied by combustion of hydrocarbons. Topsoe’s eREACT™ technology allows for the first-of-its-kind electrification of the traditional SMR process. The reaction heat for eREACT™ is instead generated directly by (renewable) electricity, thereby eliminating the flue gas altogether. Having gone through scale-up from bench scale to industrially relevant pilot scale the technology is now ready for industrial application.