Sulphuric acid recycling

As producers and regulators become increasingly concerned about the ‘circular economy’, there is increasing focus on regenerating waste sulphuric acid for re-use.

As producers and regulators become increasingly concerned about the ‘circular economy’, there is increasing focus on regenerating waste sulphuric acid for re-use.

In this case study AGRU Kunststofftechnik reports on how a new condenser design, engineered by OMV and INWA AG using PFA sheets from AGRU, was implemented at OMV refinery in Austria to address maintenance problems due to corrosion of the wet sulphuric acid (WSA) condensers and the follow-up units.

A new burner design for the combustion of natural gas with either combustion air or pure oxygen as the oxidiser has been developed by CS Combustion Solutions. The new Oxijet®-Burner has been designed to perform both start-up and main operation functions with one burner.

Comprimo and Ametek now offer the Analyser Air Control Technology (2ACT) Solution to the industry which enables operating companies to control their assets closer to design capacity at higher recovery efficiency and with fewer unscheduled outages.

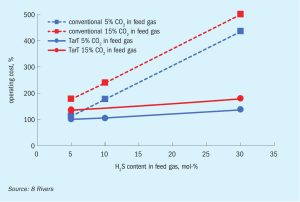

TarT technology, one of 8 Rivers’ decarbonisation technologies, shows promise as an economical, efficient, sour gas sweetening process with near-zero carbon dioxide emissions, and may be key to unlocking access to the world’s sour gas reserves.

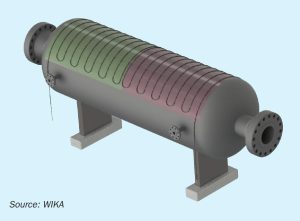

WIKA discusses a novel and easy way to monitor the shell temperature of the Claus thermal reactor using proven technology and highlights the benefits a purge-less thermocouple system for high temperature measurement.

Ballestra, Nitricity, Solex Thermal Science and Stamicarbon showcase their state-ofthe-art equipment and technologies.

The quality of finished fertilizers can be maintained during transport, handling and storage by protecting the surfaces of granules and prills with coating agents. Valuably, fertilizer coatings can also be used to control the release of nutrients in the field.

Intermodal Solutions Group (ISG) is introducing a container-based storage, transport and ship loading system for bulk fertilizers. The company’s innovative Pit to Ship Solutions ™ system could transform fertilizer logistics and help the sector meet its environmental, social and corporate governance (ESG) goals.

Antoine Hoxha, the new Director General of Fertilizers Europe, looks ahead at the future of the EU fertilizer industry, setting out his vision of an industry transformed by decarbonisation, new energy markets, sustainable agriculture and the circular economy.