Low carbon ammonia capacity

A review of the current slate of plans for green and blue ammonia production.

A review of the current slate of plans for green and blue ammonia production.

The production and use of nitrogen fertilizers are responsible for around five percent of global greenhouse gas (GHG) emissions. The fertilizer industry will need to drastically cut these emissions by 2050 as part of its contribution to the 1.5 °C global warming target. Yet around 48 percent of the global population rely on crops grown with nitrogen fertilizers. Guaranteeing food security, by continuing to supply affordable crop nutrients at scale, while transitioning to a low-carbon future, is therefore the collective challenge for the global fertilizer industry and world agriculture.

The need for immediate climate action and cuts in carbon emissions has never been more urgent, especially in a world where ecosystems are increasingly under threat. The production of green fertilizers offers a clear route to achieving these goals by decreasing the chemical industry’s reliance on fossil fuels. Stamicarbon’s Carmen Perez, Rolf Postma and Nikolay Ketov outline the company’s innovative and integrated approach to green fertilizer technology.

Fertilizers will always be fundamental to food production, but they will also have to be low emissions, environmentally friendly and support healthy soils. In this article, Dr Alexander Schmitt, Chief Marketing Officer, Anglo American Crop Nutrients, explains how polyhalite meets all three of these criteria – while also helping to increase the quantity and quality of food a farmer can produce.

The Aecometric 3rd generation burner was developed, installed and commissioned for an SRU incinerator with increased stringent demands to reduce NOx emission and lower energy consumption. Mason Lee of Aecometric Corporation reports on the new burner design and performance. The emission test results show a significant improvement in addressing these environmental concerns to achieve low NOx (<50 mg/m3 ) combustion and minimise CO (<200 mg/m3 ) emissions.

Sulphur Experts outline the steps required to determine optimised SRU incinerator operating conditions. Although a proper determination of the ideal SRU incinerator operating conditions for any given facility is complicated by a combination of inconsistent permitting standards and poor understanding of the role of the SRU incinerator, the payoff for incinerator optimisation is a significant decrease in natural gas usage with corresponding savings in operating costs, a decrease in CO2 emissions, and a simultaneous reduction in NOx and SO3 emissions.

Low emissions hydrogen is expected to play an increasing role in the syngasbased chemicals industry, but cost and technical challenges remain.

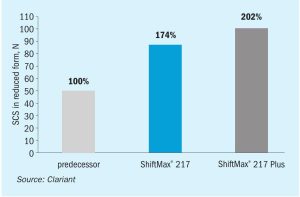

Anton Kariagin and Stefan Gebert of Clariant discuss the benefits and commercial performance of the new low temperature shift (LTS) catalyst – ShiftMax 217 Plus. A case study demonstrates the benefits of this catalyst, providing ultra-low methanol formation resulting in increased ammonia production and/or energy savings.

Ammonia has been recognised as an advantageous hydrogen and energy carrier. This article focuses on the use of ammonia as fuel in steam reformers and ammonia crackers in order to reduce or completely eliminate direct CO2 emissions. Ammonia combustion knowledge is especially important for ammonia crackers with respect to the recycling of unconverted ammonia. Air Liquide is constructing an industrial scale pilot plant in Antwerp, planned to be operational in 2024, that will be used to demonstrate ammonia cracking and combustion in a process furnace with a multiple burner configuration.

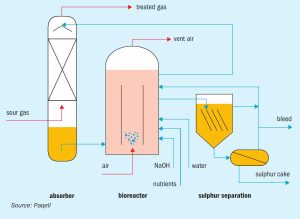

As environmental SO2 emission regulations become more stringent, tail gas treating options become limited. To potentially achieve lower opex and improved plot plan, utilising a biological desulphurisation process as an alternative to a conventional amine-based TGT unit is becoming of increased interest in the oil and gas industry. At the same time, demands for increased SRU capacity and reliability favour the use of medium and high-level oxygen enrichment.