Safer and sustainable nitrates production

State-of-the art technologies offered by thyssenkrupp, Casale and Stamicarbon are helping make nitrates production more secure and sustainable.

State-of-the art technologies offered by thyssenkrupp, Casale and Stamicarbon are helping make nitrates production more secure and sustainable.

Last year the International Energy Agency (IEA), in conjunction with IFA, published the Ammonia Technology Roadmap, which looks at ways of achieving decarbonisation of the nitrogen fertilizer industry by 2050. In this article we look at the scenarios and technology options that will define the industry over the next three decades.

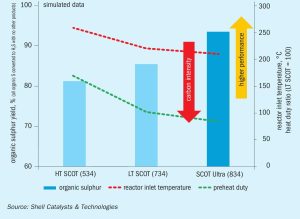

Decreasing the carbon intensity of sulphur recovery is one of the many actions that operators can take to help meet their climate ambitions. It is also becoming increasingly rewarding financially because of the rising cost of carbon emissions. In this article, G. Kidambi of Shell Projects & Technology demonstrates the potential to cut the carbon intensity of tail gas treating units by more than 50% through swapping to the latest SCOT ULTRA amine solvent and catalyst technologies.

Nitrogen-rich wastewaters remain a major issue for fertilizer and other industries. Saipem’s new electrochemical technology, SPELL, is an important step towards the overall objective of zero industrial pollution. A complete engineering review of the technology, its alignment with all international applicable standards, and optimisation has now been concluded and the technology is ready for deployment for the removal of ammonium nitrogen from industrial waters and wastewaters. Saipem discusses the key features of SPELL and reports on the first two industrial references.

Considering the current shift to produce biofuels instead of conventional oil products, M. van Son of Comprimo discusses the impact that this may have on the ability to process the sour water acid gas streams produced in existing or new sour water strippers.

Major fertilizer industry players such as Stamicarbon, Nutrien and CF Industries are ramping up investment in ‘green’ and ‘blue’ fertilizer production. Consequently, low-carbon production technologies are being scaled-up and deployed commercially.

Buss ChemTech AG offers the international phosphate industry a robust solution to create added-value products from fluorosilicic acid (FSA). Thomas Dahlke, the head of the company’s process engineering department, and Emre Sen, sales manager for fluorine technologies, explain how this can be done in a sustainable manner.

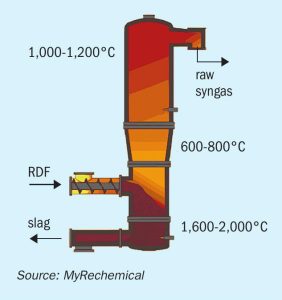

Johnson Matthey and MyRechemical have formed an alliance to commercially develop waste to methanol technology. In this article, two different approaches to waste disposal and chemical production are analysed: a post combustion scenario with waste incineration and hydrogenation of the CO2 recovered from flue gas to produce methanol, and a precombustion approach with waste gasification followed by conversion of synthesis gas into methanol.

The European Union is seeking to create a climate-neutral and circular economy through its flagship Green Deal policy. The fertilizer industry can support these objectives by adopting inhibitor treatment technology (ITT) and controlled-release fertilizers (CRFs) based on biodegradable polymers. These two innovations have a vital role to play in improving nitrogen use efficiency and the shift towards more sustainable resource use, says Dr Matthias Potthoff of thyssenkrupp Fertilizer Technology.

Plans to decarbonise power production and shipping are leading to increasing interest in using ammonia as a fuel, but technical and economic barriers still remain to be overcome.