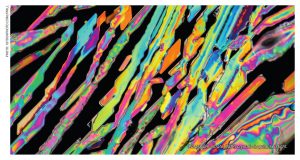

Paradeep Phosphates Ltd (PPL) has announced a $400 million capacity expansion program, following its October 13th merger with Mangalore Chemicals & Fertilizers Limited (MCFL). This company says that the move aims to strengthen PPL's market position and enhance its production capabilities. The investment will involve increasing granulation capacity by 1.0 million t/a at the Paradeep site, as well as an additional 250,000 t/a of phosphoric acid and 750,000 t/a of sulphuric acid capacity at the company’s new Mangalore site. The expansion is expected to be completed within three years, according to PPL, and is expected to ensure 100% backward integration for fertilizer production, reduce import dependency, and enhance operational capabilities and profitability. low-contaminant phosphate concentrate that allows for easy conversion into purified phosphoric acid. The company has spent over C$100 million advancing the project and has received funding and investment from the Quebec Government.