Lowering CO2 emissions with EARTH® technology

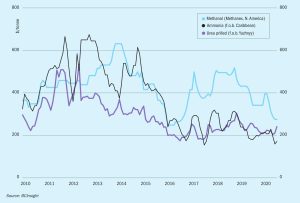

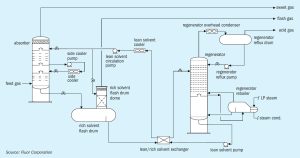

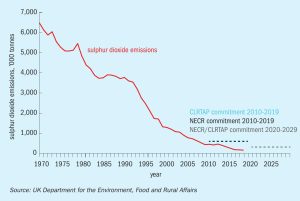

TechnipFMC’s EARTH ® technology, with its structured catalyst jointly developed by TechnipFMC and Clariant, has been proven to be a cost effective way to drastically improve productivity and energy efficiency of the steam reforming process, while reducing the CO 2 footprint per unit hydrogen and syngas product. The technology can be applied in projects to increase the capacity of ammonia and methanol plants and allows significant reduction of greenhouse gas emissions. S. Walspurger of Technip Benelux B.V. and S. Gebert of Clariant GmbH report on the EARTH ® technology and its applications.