CRU acquires BCInsight’s industry publications

The ownership of Fertilizer International magazine transferred from BCInsight Ltd to CRU, the global commodities experts, at the start of the year.

The ownership of Fertilizer International magazine transferred from BCInsight Ltd to CRU, the global commodities experts, at the start of the year.

With phosphate supply concerns persisting as 2023 draws to a close, CRU’s Senior Analyst Logan Collins looks back at what’s been a dynamic year for the global phosphate market.

We look ahead at fertilizer industry prospects for the next 12 months, including the key economic and agricultural drivers likely to shape the market during 2024.

For 50 years, Kimre engineers and application specialists have been solving process and gas stream emission problems in chemical and fertilizer plants around the globe. In an exclusive interview, Kimre’s new president Mary Gaston sets out her plans for the company, building on its invaluable understanding of gas and vapour stream separation and mass heat transfer.

In a recent webinar, Chris Lawson, CRU’s Head of Fertilizers, gave the CRU view on what 2024 holds in store for the global fertilizer industry. Here are CRU’s top 10 calls for the year ahead:

We are very pleased to be able to tell you that, as of this issue, Nitrogen+Syngas magazine has a new publisher. Or rather, an old publisher, as the magazine is now once again part of the CRU Group.

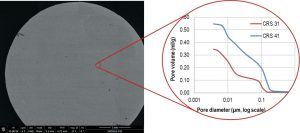

Axens has developed a new titania-based catalyst named CRS 41, which has a much larger porosity than its renowned predecessor, CRS 31 catalyst. Thanks to an improved catalyst manufacturing process and a new recipe, the porosity of CRS 41 has been increased while preserving the mechanical resistance for loading, allowing customers to optimise their capex by either reducing the Claus reactor size or loading volume of TiO2 catalyst.

Sulphur prices are expected to increase during H1 2024, reversing the trend of recent declines, though good availability will limit the upside to price gains in the short term. However, should fertilizer production prove weaker than expected, prices may remain below expected levels.

This case study reports on the successful collaboration of two experienced partner companies to replace the problematic upper part of a co-current flow quench tower in a spent acid plant and shows the benefits of using resistant, pre-lined workshop fabricated equipment.

“ The need for technical knowledge and insights has never been more important.”