Nitrogen+Syngas 399 Jan-Feb 2026

27 January 2026

Problem No. 76 Additives to improve quality of prills

- significant higher plant production capacity;

- nitrogen and sulphur (and calcium) as nutrients in one prill (higher nitrogen use efficiencies);

- significant higher crushing strength;

- large particle size; negligible additional heat load on prilling tower;

- smaller product size distribution with the Kreber Vibro prilling bucket;

- no formaldehyde but coating will be required;

- lower ammonia and dust emissions;

- biuret formation stops;

- payback times of only a few months.

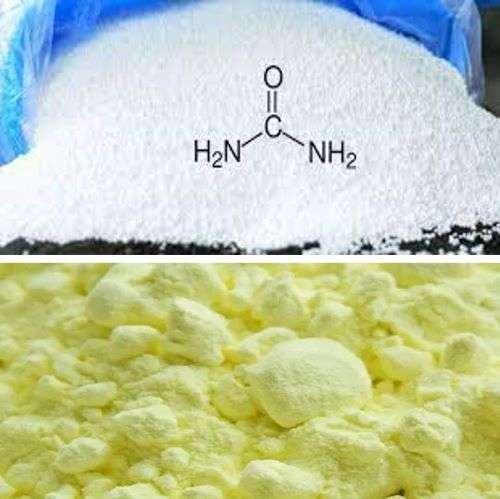

Urea + ammonium-sulphate fertilizers (UAS)

Sulphur deficiency occurs widely in many parts of the world, due to a combination of factors: reduced use of single super phosphate, which contains gypsum (CaSO4), more sulphur being removed from fields due to increasing yields, and declining soil reserves due to erosion and leaching. In addition, emissions of sulphur dioxide from burning fossil fuels have historically provided a large sulphur input to soil, as both rain and deposition of dust. As these emissions reduce, so soil deficiencies are increasing. Fertilizers enriched with S are now increasingly used to correct sulphur deficiencies. A better source of sulphur may be ammonium sulphate (AS), which makes the sulphur available in a form that can be directly taken up by plants.

A nitrogen plus sulphur fertilizer can enhance the utilisation rate of nitrogen due to their well-known synergy; plants need sufficient levels of sulphur to be able to utilise nitrogen efficiently. Together, nitrogen and sulphur are vital building blocks for protein, and should be applied at the same time.

Urea + gypsum fertilizers (UCS)

Phosphoric acid is a major feedstock for phosphate fertiliser, but, for every tonne of acid produced, an average of 5.4 t of phosphogypsum (PG) is created. The outcome is that the annual PG output of International Fertiliser Association (IFA) members is in the range ~225-245 million tonnes. This amount and its contaminants pose a significant challenge for the industry to achieve better sustainability performance. Urea is the most widely used nitrogen fertiliser with some 200 million tonnes sold annually but suffers from significant nitrogen losses through ammonia volatilisation, CO2 loss, as well as N2O emissions and nitrate leaching. The emissions of CO2 and N2O contribute significantly to the carbon footprint of urea fertilisers. These two issues form possibly the two major environmental challenges in our industry. Urea with gypsum represents a potential next-generation fertiliser. It can deliver improved agronomic performance and higher nitrogen use efficiencies. And, because of the large volume of urea use, it can potentially contribute significantly to the reuse of PG. By recycling industrial gypsum wastes and reducing nitrogen losses, the use of urea-gypsum fertilisers aligns with global goals for climate-smart, resource-efficient agriculture.

Joao Amilton from Petrobras in Brazil initiates this round table discussion: What are the best additives to improve crushing strength and anti-caking resistance of prills? We operate with formaldehyde 37% and PVA solution (polyvinyl acetate). The medium crushing strength of our prills is about 0.654 kgf with formaldehyde (0.440 kgf without). The prill tower design is TEC induced-draft (original project was 800 t/d, but today operates at 1,350 t/d). Our operators don’t like to work with formaldehyde because it’s toxic to human health.

Mark Brouwer of UreaKnowHow.com, The Netherlands replies: I know, introduce another anti caking agent, URESOFT 150, that can be sprayed on the belt conveyor and which has no bad effect on human health.

Joao comes back with another question: Do you know URECOAT 2000 and Urefix?

Al-Mohaws of SABIC Agri-Nutrients in Saudi Arabia joins the round table discussion and shares his experience: We are using UF-85 (urea formaldehyde) to improve the crushing strength plus URESOFT 150 as an anti-caking agent. As regards URECOAT 2000, we have used it but we prefer URESOFT 150. We keep URECOAT 2000 as a stand-by in case of shortage of Uresoft 150.

Hana Stepic of Petrokymia, in Croatia joins the discussion: We use LENDAFORM 70 (urea formaldehyde) to improve crushing strength. We don’t use anti-caking agent any more.

Les Farbotko, formerly of Incitec Pivot Limited in Australia, shares his valuable experiences: We have used formaldehyde, UF-75 and URESOFT 150 in the past when we made prills.

I believe UF-75 is far more user friendly than 37% formaldehyde, and poses much less risk to operators. As well as making prills harder, it also reduces caking tendency.

URESOFT 150 needs to be applied uniformly to the product if it is to be effective. This usually means multiple spray nozzles and some form of mixing drum. If you don’t do this, you can make your caking problems worse than if you had not applied anything!

In my experience, UF75 was more effective than URESOFT 150, because it is easy to apply uniformly to every prill, and contains only a small amount of water, which is evaporated anyway.

Serpoush of Shiraz Petrochemical Complex in Iran asks for more information about PVA.

Janusz Mackowski of ZCh Police in Poland joins the discussion: I can imagine that PVA is added to prilled final product. What is your experience with polyvinyl acetate?

We tested a similar solution as anti-caking agent but we weren’t very happy with it.

We also use urea formaldehyde condensate (highly concentrated) to improve the mechanical strength (introduced to melt of urea).

Joao replies: We use PVA solution too, but it’s very uncomfortable to work with. Operators should dilute the concentrate PVA solution before injecting in urea prills. Pipes and pumps are frequently blocked and the humidity of urea increases.

Serpoush comes back: OK, so you are using UF-85 (urea formaldehyde) to improve crushing strength plus URESOFT 150 as anti-caking agent. Have you measured the improvement? How much improvement in urea crushing strength do you have in the prills? Do you have a fast method to test this improvement?

Janusz replies: You can achieve about 30% increase in crushing resistance of prills by adding concentrated UFC-85 to urea melt. The simplest way to measure this increase is to use laboratory scale and pencil. Of course you can also apply more advanced devices like those which are used to measure the resistance of small pastilles.

Mark rejoins the discussion: Adding solid additives like AS or gypsum proves to be a very effective way to improve your prill quality; larger prills, higher crushing strengths and multi-nutrient fertilizer plus very low pay back times.