Nitrogen+Syngas 399 Jan-Feb 2026

19 January 2026

Wire-based additive manufacturing for HP equipment

UREA AND AMMONIA PLANT EQUIPMENT

Wire-based additive manufacturing for HP equipment

Christof Group SBN is actively integrating advanced manufacturing solutions such as wire arc additive manufacturing (WAAM) into its portfolio for the manufacture of high-pressure equipment in urea and ammonia plants. WAAM technology is especially suitable for niche materials customised for high corrosion resistance to carbamate solution and addresses the need for fast and tailored manufacturing of spare parts explain Aleksandra Gavrilovic-Wohlmuther and Serhiy Budnyk of Christof Group SBN.

For decades, Christof Group SBN has been at the forefront of manufacturing highly complex, safety-critical high-pressure equipment for the fertilizer, chemical and petrochemical industries. Renowned for its engineering excellence, the company delivers tailor-made high-pressure, high-temperature heat exchangers and reactors that play a vital role in urea and ammonia synthesis worldwide.

Today, this expertise is evolving in step with a new wave of technological innovation. As the industry intensifies its focus on resource efficiency, energy reduction and environmentally responsible production, Christof Group SBN is actively integrating advanced manufacturing solutions into its portfolio. One of the most promising developments is wire arc additive manufacturing (WAAM), which is rapidly establishing itself as a viable industrial production method for complex components made from niche, high-performance alloys. WAAM enables fast and efficient production of super duplex parts with exceptional corrosion resistance and mechanical performance, that are recognised as key requirements for harsh urea plant environments. Beyond design freedom, the WAAM technology offers a compelling sustainability advantage since it drastically reduces material waste, compared to traditional subtractive processes such as milling.

A particularly attractive application lies in the on-demand manufacturing of spare parts for long-lifecycle systems, where availability, lead time and waste reduction are critical factors. Rapid, WAAM-based production, as demonstrated by Christof Group SBN, has the potential to improve spare-parts availability while reducing inventory requirements and waste. Overall, the integration of additive manufacturing (AM) technologies supports more sustainable and resilient production concepts for high-pressure process equipment.

The status quo

Super duplex stainless steels (SDSS) combine high mechanical strength with outstanding corrosion resistance, a result of their carefully balanced austenite to ferrite microstructure. These characteristics make SDSS the material of choice for components exposed to both high mechanical loads and aggressive corrosive environments. Typical applications include valves, heat exchanger tubes, pumps, shafts, impellers and rotors, operating in demanding process conditions. As niche materials, SDSS may suffer from relatively long delivery times and are limited to a few standard forms such as tubes, pipes, bars and plates/sheets. As a result, aspects such as sustainability and resource efficiency are often not adequately addressed.

AM is increasingly gaining attention as an alternative to conventional casting, forging and machining for the production of metallic components, including those made from SDSS. The technology offers clear advantages in terms of design flexibility, material efficiency and lead-time reduction. However, translating the excellent intrinsic properties of SDSS into additively manufactured parts remains a technical challenge. While some studies confirm that AM-processed SDSS generally retain good corrosion resistance, variations in mechanical performance have been reported, particularly under tensile and fatigue loading. These effects are often linked to residual porosity, which can reduce resistance to cyclic stresses and lead to scatter in mechanical properties. At the same time, controlling the microstructure during deposition remains critical. The high thermal input inherent to many AM processes can alter the ferrite to austenite balance, promote inhomogeneous grain structures, or lead to the formation of undesirable secondary phases, each of which can negatively affect material performance. Process parameters and their control therefore play a decisive role. Moreover, the choice and composition of shielding gas significantly influence arc stability, material transfer and melt pool behaviour. By optimising shielding gas chemistry and process parameters, manufacturers gain an additional lever to refine the deposition process, enabling improved control of microstructure and, ultimately, more consistent mechanical and corrosion properties in additively manufactured SDSS components.

AM technology at Christof Group SBN

Over the past few years, Christof Group SBN has invested in a series of focused R&D initiatives to optimise the mechanical performance and corrosion resistance of various materials, including SDSS, with the aim to better understand how the microstructure evolves during AM processing. In particular, WAAM technology was of interest, as it is the AM process that combines continuous metal feeding in the form of wire and arc-assisted deposition technique, to create large and near net shape, complex 3D structures. WAAM offers several advantages vs. alternative AM technologies like laser-assisted powder sintering routes, by offering comparatively lower welding equipment’s cost, easily available feedstock in the form of standard commercial metal wires and a higher deposition-rates. Compared with established steel manufacturing practices, WAAM offers significantly higher productivity, with deposition rates of up to 5 to 10 kg/h. An additional advantage of WAAM is that the maximum printable size depends primarily on the range of the welding robot used. The maximum printable dimensions of up to several metres can be increased by using robot tracks and welding manipulators. The combination of WAAM and subsequent milling enables the production of relatively complex shapes. This also means that topological optimisation and the production of generatively designed parts become more accessible. Compared to other direct energy deposition (DED) systems, such as direct metal laser sintering or additive electron beam manufacturing, WAAM offers relatively lower costs, due to reduced material wastes. Another peculiarity of the WAAM is the possibility to design functionally graded components where multiple materials can be combined to design a single component. Used materials are only deposited in agreement of target shape. This is especially important for workpieces that are traditionally milled from solid blocks and/or workpieces that are made from expensive materials.

Results on UNS S32906 super duplex stainless steel

UNS S32906 is one of the most significant materials for urea critical process equipment. This material is designed to reach high requirements of mechanical strength, outstanding corrosion resistance and good weldability. To address the need for fast and tailored manufacturing of spare parts made of UNS S32906, Christof Group SBN initiated intensive R&D collaboration with hardware manufacturers, with the aim to successfully establish WAAM process parameters that guarantee mechanical and corrosion properties comparable to those of conventionally manufactured components. The wire feedstock used for this study is commercially available UNS S32906 wire with a diameter of Ø1.2 mm.

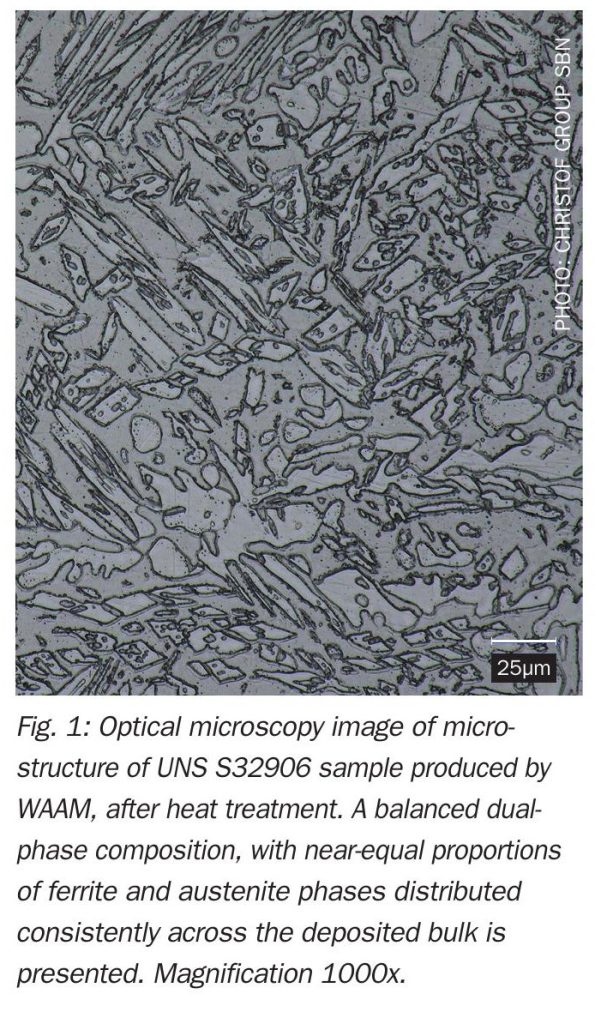

Microstructural examinations of the fabricated specimens revealed a balanced dual-phase composition, with near-equal proportions of ferrite and austenite phases distributed consistently across the deposited bulk (Fig. 1).

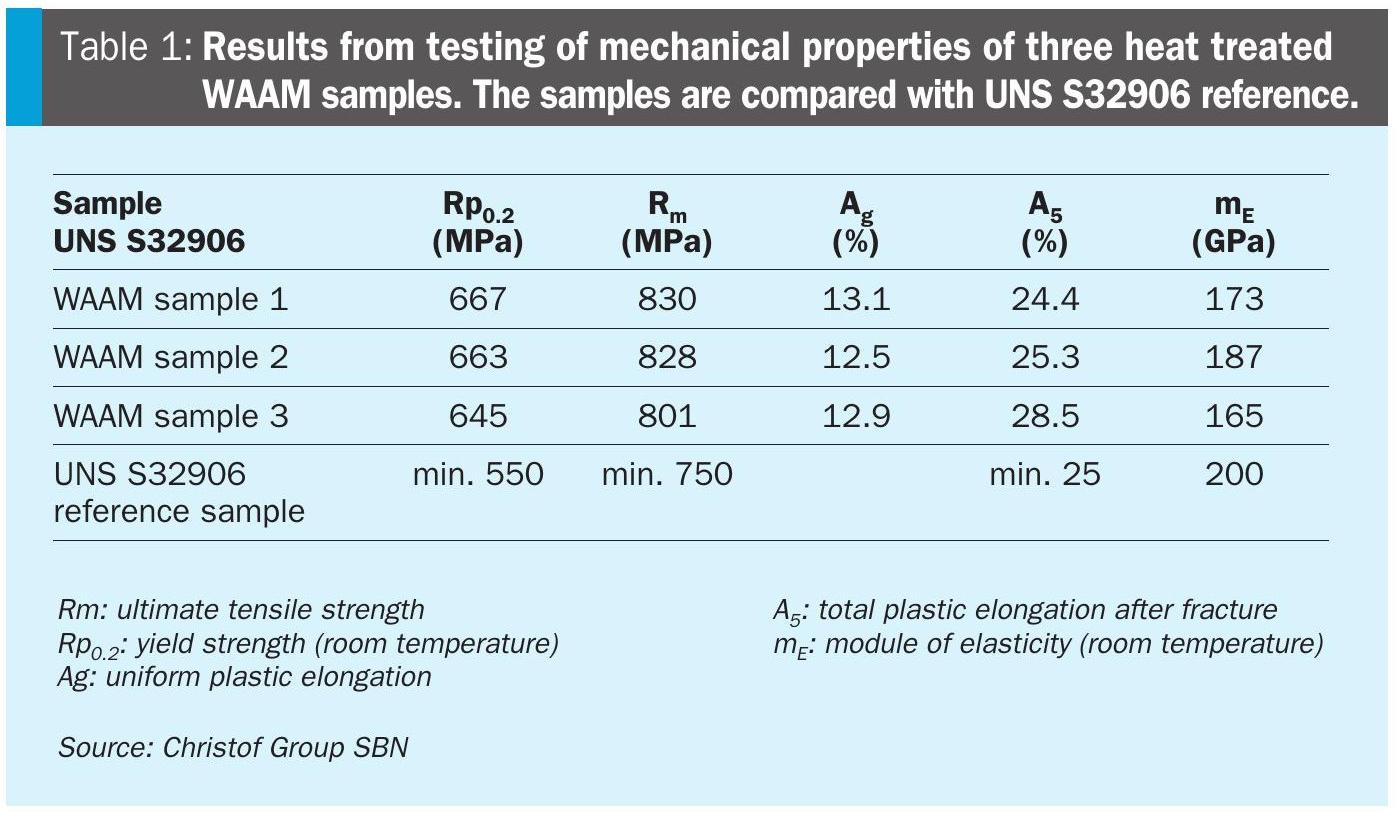

Mechanical testing, including assessments of yield strength, elongation and ultimate tensile strength in both, the build and travel directions, confirmed that controlled WAAM delivers samples that match the performance of their wrought counterparts (see Table 1). This indicates that the WAAM process preserves the inherent mechanical advantages of UNS 32906.

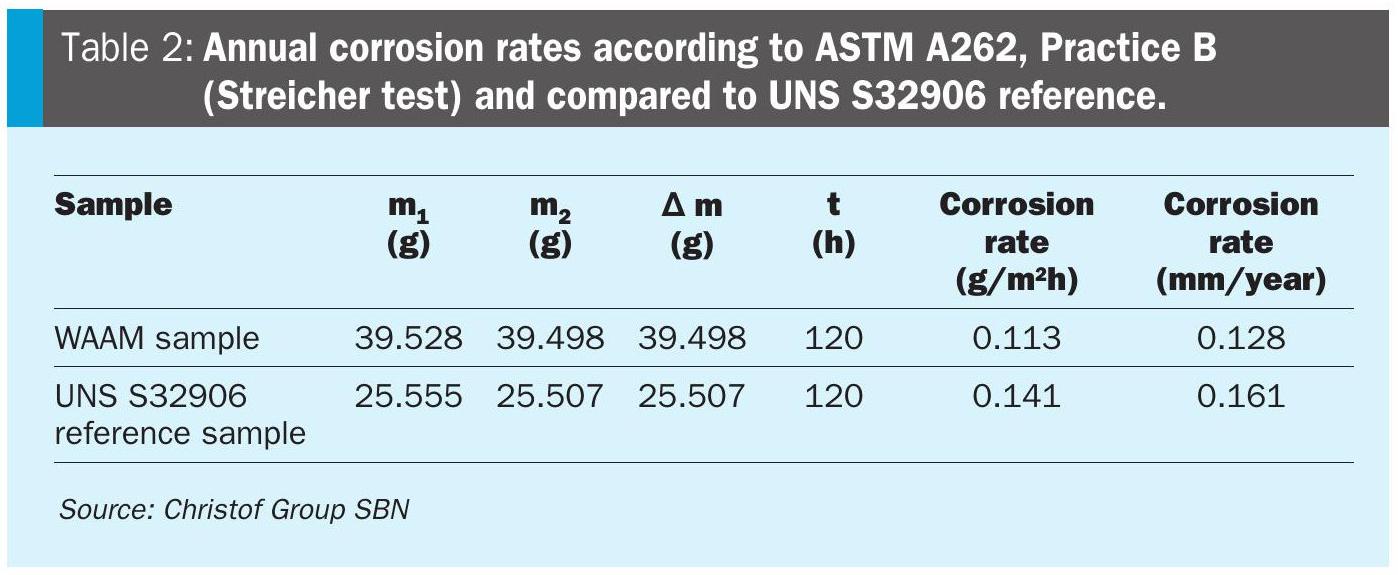

To evaluate corrosion performance, the samples are subjected to testing according to ASTM A262, Practice B. The results of the Streicher test reveal an annual corrosion rate of the WAAM sample that is significantly lower than the threshold of 0.6 g/m2 h, according to the applicable customer specification. Interestingly, the annual corrosion rate of the WAAM sample is considerably lower in comparison to the annual corrosion rate of the commercially available UNS S32906 reference sample material (Table 2).

The first attempts of Christof Group SBN to produce simple shapes with SDSS showed that the welding parameters and shielding gas play a decisive role in achieving a high-quality microstructure, but the creative choice of build-up strategy also plays an important role. Elaborated sets of parameters allow construction parts of UNS 32906 to be produced with a thickness of over 45 m, reaching the quality equal to traditional metallurgical routes such as forging, casting and cold forming (Fig. 2).

Conclusions

To address the need for fast and tailored manufacturing of spare parts, Christof Group SBN has developed a reliable solution using WAAM. This technology is especially suitable for niche materials customised for high corrosion resistance to carbamate solution. Through an intensive R&D initiative WAAM process parameters are successfully established. The procedure guarantees mechanical and corrosion properties comparable to those of conventionally manufactured metal components. Most notably, corrosion testing in simulated process environments, conducted in accordance with recognised standards, has demonstrated exceptional corrosion resistance. This positions additive manufacturing of UNS S32906 components as a viable alternative to traditional spare parts production methods, such as forging, casting, hot/cold forming, or powder-based metallurgical routes followed by subtractive machining with an overall drastic improvement of the delivery time.

The WAAM process enables near-net-shape manufacturing of customised geometries, making it particularly suited for complex, or obsolete spare parts, while minimising material waste. The primary benefit to clients is a considerable reduction in lead times. This allows a significant competitive advantage by improving plant availability, reducing costs while enabling fast recovery from planned and unplanned outages without compromising the quality and property.