Sulphur 421 Nov-Dec 2025

24 November 2025

SRU optimisation through continuous monitoring

DIGITAL TOOLS

SRU optimisation through continuous monitoring

Continuous monitoring of sulphur recovery units (SRUs) has proven to be an excellent tool for energy optimisation and emissions reduction, yielding financial incentives in the form of CO2 credits and sustainability. Even in markets with limited CO2 credits, significant economic benefits can still be realised through reduction in utility consumption, as demonstrated by a recent collaboration between Worley Comprimo and PRefChem in Malaysia.

Claudia Guarino (Comprimo) and Gokul Sundaramoorthy (PRefChem)

Energy optimisation and greenhouse gas (GHG) emissions reduction are increasingly important as global efforts intensify to combat climate change. These efforts have triggered actions by the industry to either implement greener technologies or energy-optimise existing process configurations. In the latter case, continuous monitoring services such as Comprimo Insight, play a key role by providing a deeper operational insight, allowing for timely adjustments to reduce the plant energy footprint and operating cost.

This article summarises the use of Comprimo Insight to enable monitoring services in a sulphur recovery unit (SRU) at PRefChem in Malaysia to enhance energy efficiency while meeting sustainability and environmental requirements. The Comprimo Insight tool is a near real-time monitoring system that allows visualisation of plant performance and trends in KPIs tailored specifically to the needs of PRefChem. This capability allows for rapid evaluation and implementation of guidance from technology specialists. As a result, the SRU utility performance has been significantly improved, with incremental high-pressure steam (HPS) export and reduced fuel gas (FG) consumption, while maintaining all environmental targets.

Implementation of the monitoring system

Implementation of the monitoring system

To be successful, a monitoring service must be cost-efficient, allowing for seamless and timely automated data transfer, and providing quick, actionable feedback to plant operations.

The data transferring architecture between the plant and the monitoring system can be concisely described, as follows, and as illustrated in Fig. 1:

- Relevant tags in the SRU are identified.

- Data from identified tags are uploaded to the client’s cyber-secured cloud environment from the client’s historian database.

- Through a secured protocol, the data are then transferred into the monitoring system’s historian database, located also in a secured cloud environment.

- Once new data are available, they are processed through calculations and simulations specifically tailored to the plant configuration and design specifics using proprietary software, using selected plant data as input, and generating results that represent the expected plant performance.

- These results populate a result database located in the monitoring system.

- The results are then passed back to the client, also via a secured protocol and in the form of a visualisation dashboard, providing the most recent values and operational trends over long periods of time.

- Technology specialists with access to this data can then provide insightful recommendations to prevent potential failures, provide guidance on potential catalyst replacements, improve plant efficiency, and reduce operating costs in an opportune manner.

Data are transferred continuously in one-minute average values. There is a delay of 10 to 25 minutes, depending on the client’s setup, between data collection and dashboard availability. In the general example presented in Fig. 1, Azure Data Explorer is used for both, the client, and the monitoring system.

Collaboration between PRefChem and Worley Comprimo

PRefChem is a refinery and the largest petrochemical complex in Malaysia, part of the Pengerang Integrated Complex (PIC) in the southern state of Johor. It has three identical SRU trains using the SUPERCLAUS® technology.

In 2023, PRefChem requested Worley Comprimo to provide ongoing technical assistance to optimise its SRUs and minimise emissions. By the third quarter of 2024, Comprimo Insight started continuously monitoring PRefChem units, collecting and analysing data, and providing recommendations to improve plant performance, and reduce both utility consumption and operating cost.

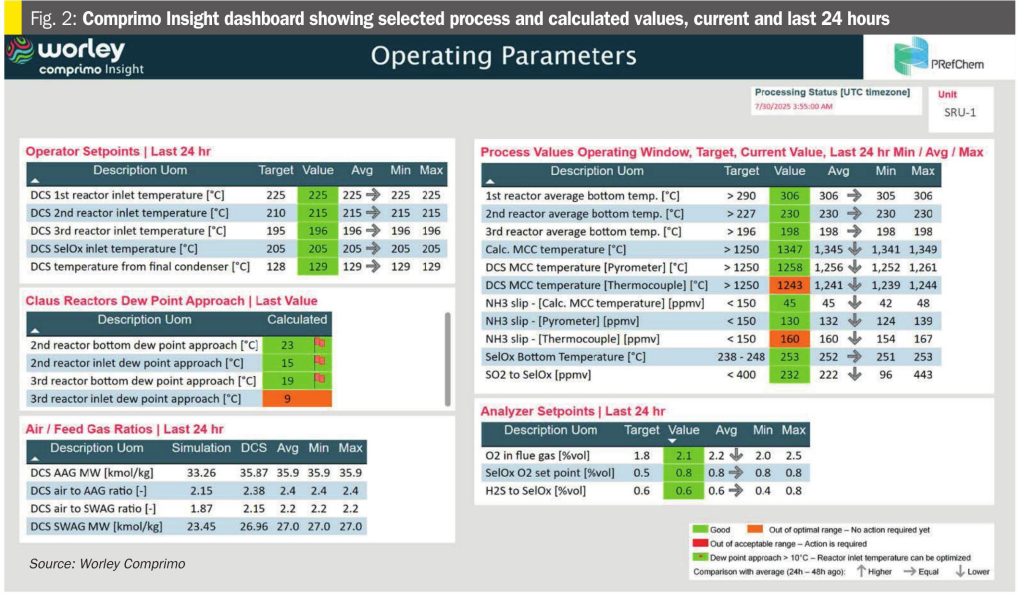

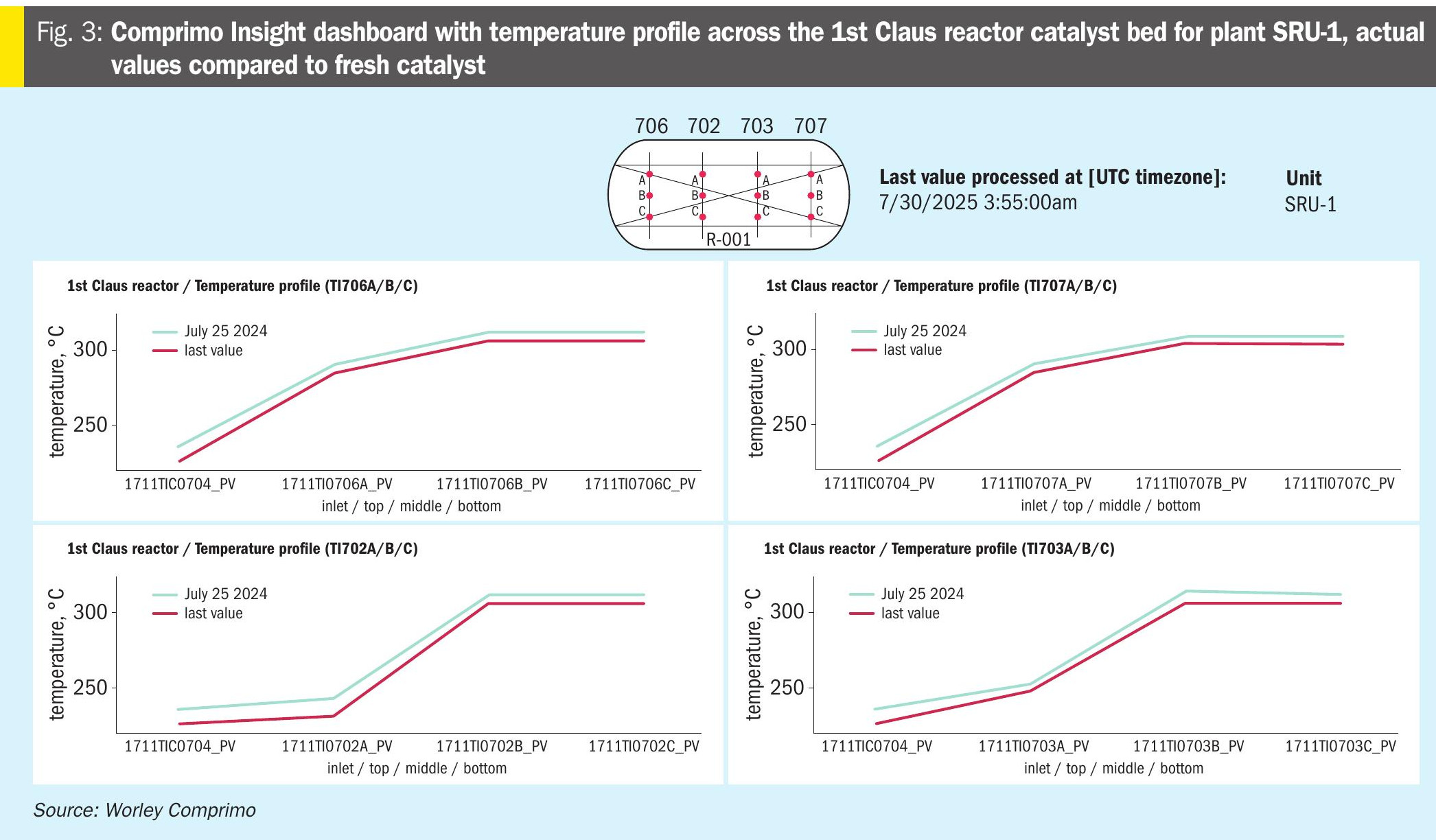

Several KPIs were developed to monitor the operation of the PRefChem SRUs, including the Claus sulphur recovery, SO2 and H2S concentrations at the stack, and other key parameters. Additionally, virtual analysers, (software tools that analyse calculated values based on other measurements), were also used to assess plant performance. Examples of virtual analysers for PRefChem include:

- Tailgas H2S to selective oxidation (SelOx) reactor: the temperature rise across the SelOx reactor is a direct measure of the H2S concentration at the SelOx reactor inlet and therefore a check of the H2S value given by the tail gas analyser.

- Main combustion chamber temperature: the temperature in the main combustion chamber is calculated based on feed gas flow rates and assumed composition.

Fig. 2 presents selected distributed control system (DCS) process parameters, calculated values as well as visual analysers that are continuously monitored by Comprimo Insight.

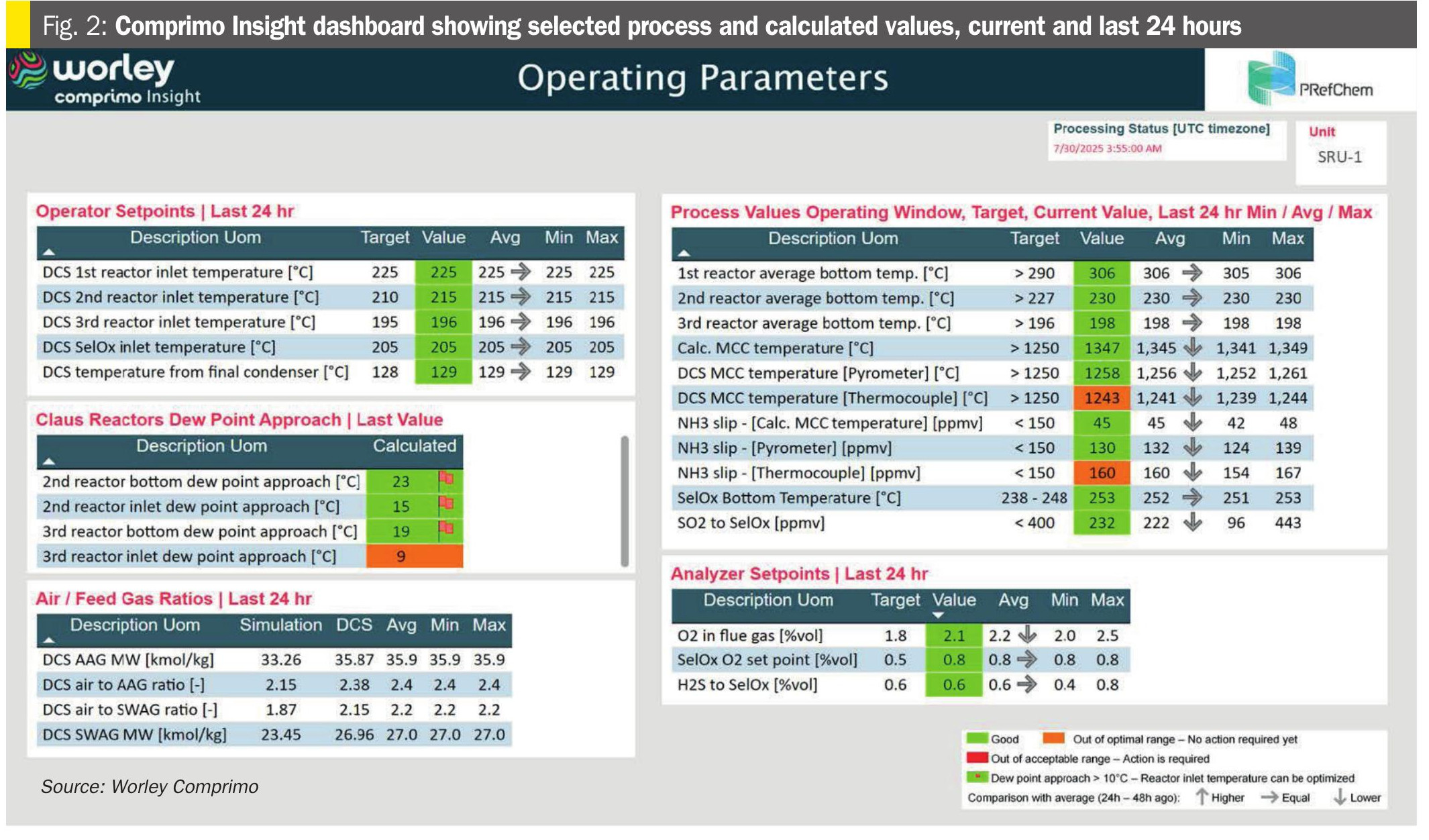

Reactor temperature profiles are also closely tracked and compared against historical data to identify potential signs of catalyst deactivation or other operational anomalies, as illustrated in Fig. 3.

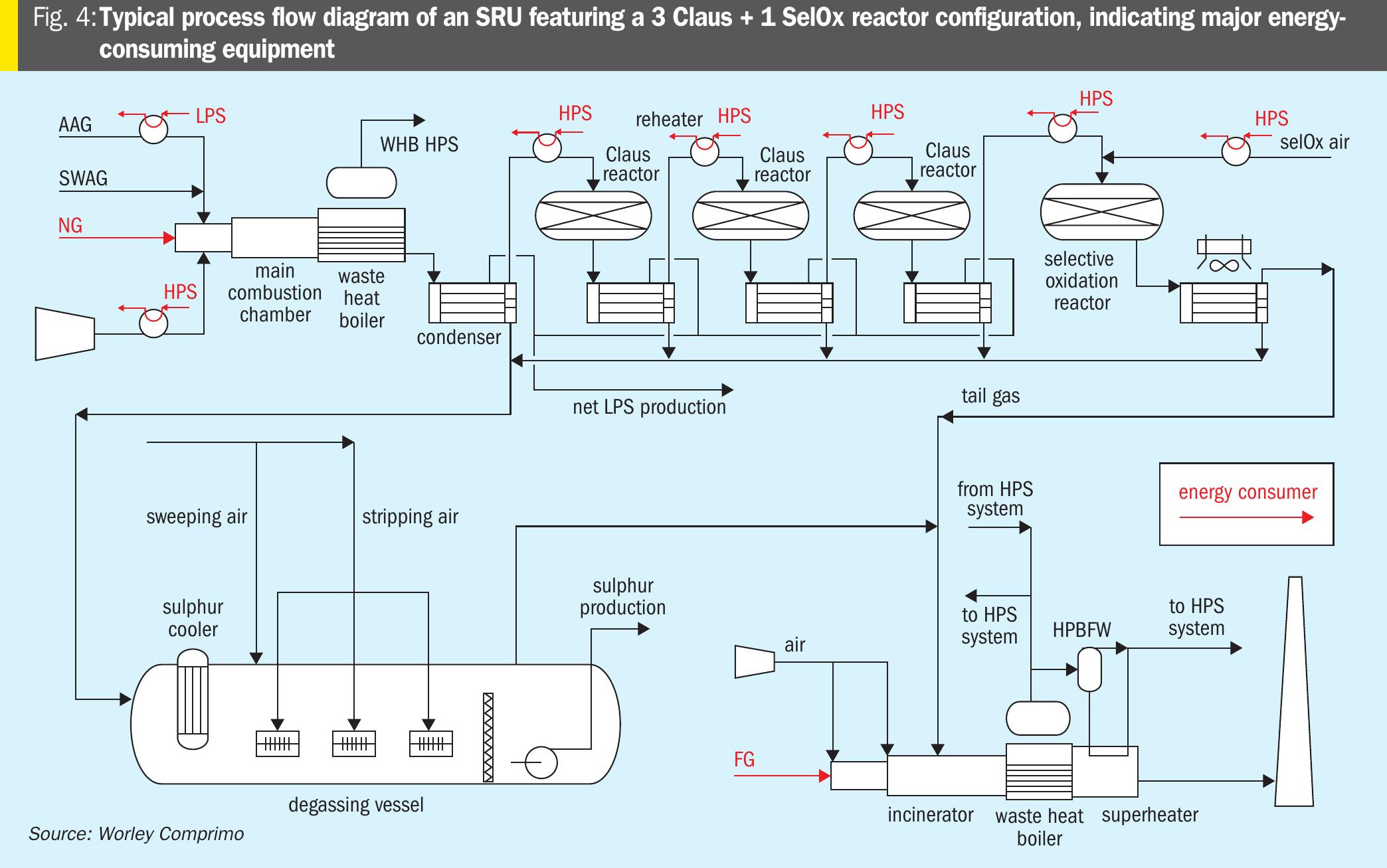

Fig. 4 shows a representative process flow diagram for an SRU configured with three Claus reactors, followed by a single SelOx reactor. Analysis of the available operational data revealed optimisation opportunities in both the Claus reactor section and incinerator operation.

Reactor operation optimisation

By continuously monitoring temperature profiles across the catalyst beds through the Claus and SelOx reactors and estimating the dew points of process gas streams using proprietary process simulation tools, the operating conditions of the reactors are systematically assessed to identify opportunities for process optimisation and energy reduction.

For example, although the reactor inlet temperatures (RIT) are typically specified by the process licensor to meet the desired plant performance, careful evaluation can reduce energy consumption in the reheaters, without adversely affecting operational efficiency.

1st reactor optimisation

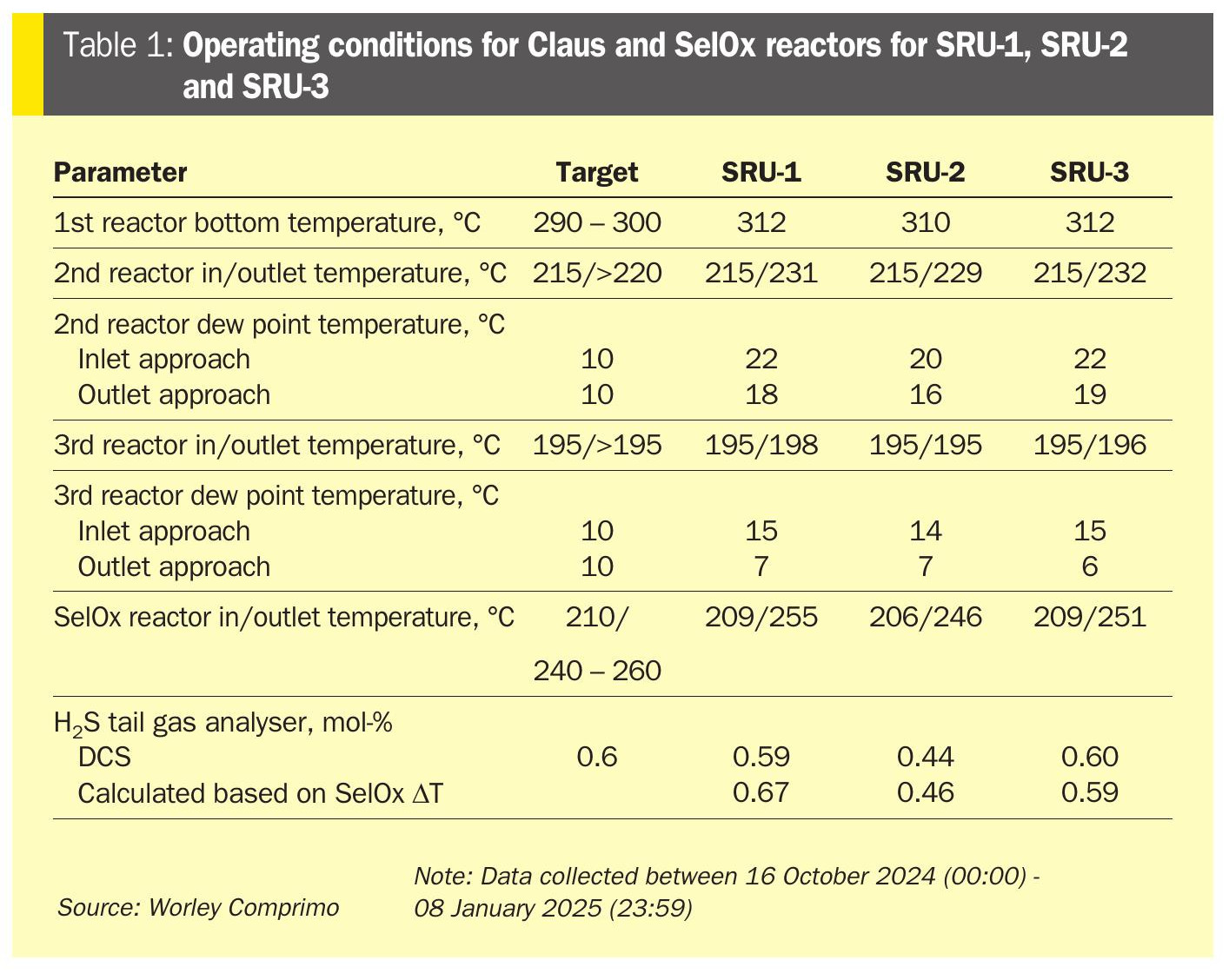

In addition to the Claus reaction, COS and CS2 destruction happens in the 1st Claus reactor, requiring an outlet temperature of at least 290°C. Table 1 shows outlet temperatures for the 1st Claus reactors for all units, typically around 310 to 312°C, giving around 20°C margin from the minimum bottom temperature required.

2nd and 3rd reactor optimisation

The 2nd and 3rd Claus reactors are operated so that the inlet and outlet temperatures are above the sulphur dew point to prevent sulphur condensation on the catalyst. Based on the data shown in Table 1, the dew point approach in the 2nd reactor is above 20°C, which is much higher than the industry standard of 10°C.

SelOx reactor optimisation

The SelOx RIT is maintained at 210 °C to ensure optimal yield. In the PRefChem 3+1 SUPERCLAUS® configuration, the typical H2S tail gas setpoint is 0.5 mol-%. Because PRefChem H2S setpoint is 0.6 mol-%, enough heat generation is expected, potentially permitting a 5°C reduction in the RIT while maintaining comparable reactor performance.

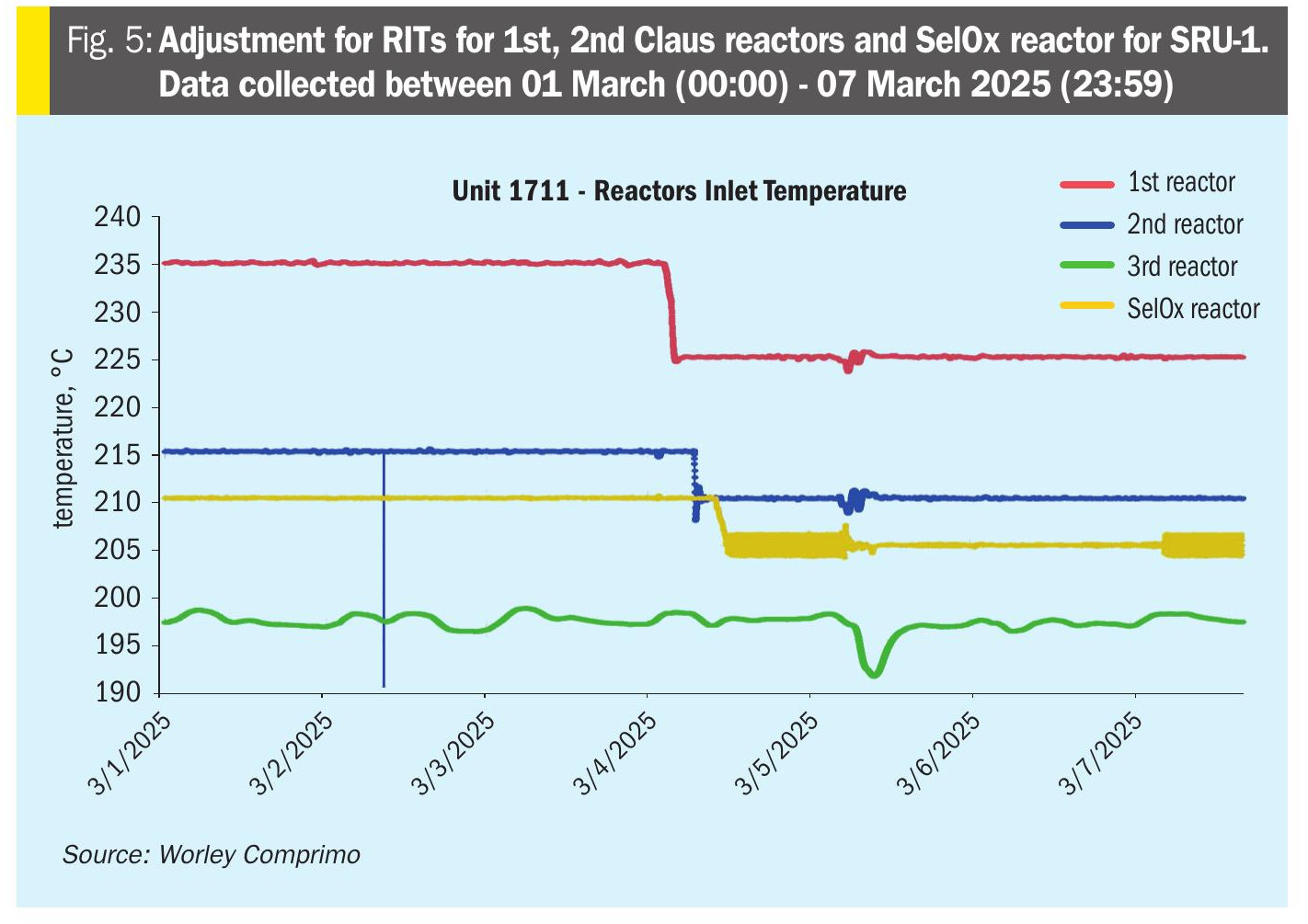

Based on the reactors operating conditions, it was suggested to decrease the RIT by 10°C in the 1st Claus reactor, and by 5°C in both the 2nd Claus and SelOx reactors to reduce HPS consumption in the reheaters, while assessing the plant performance. The 3rd reactor outlet already operates close enough to the sulphur dewpoint.

PRefChem carried out a test, decreasing the RIT in the reactors for all three units as shown in Fig. 5, and it was demonstrated that the plant performance was maintained.

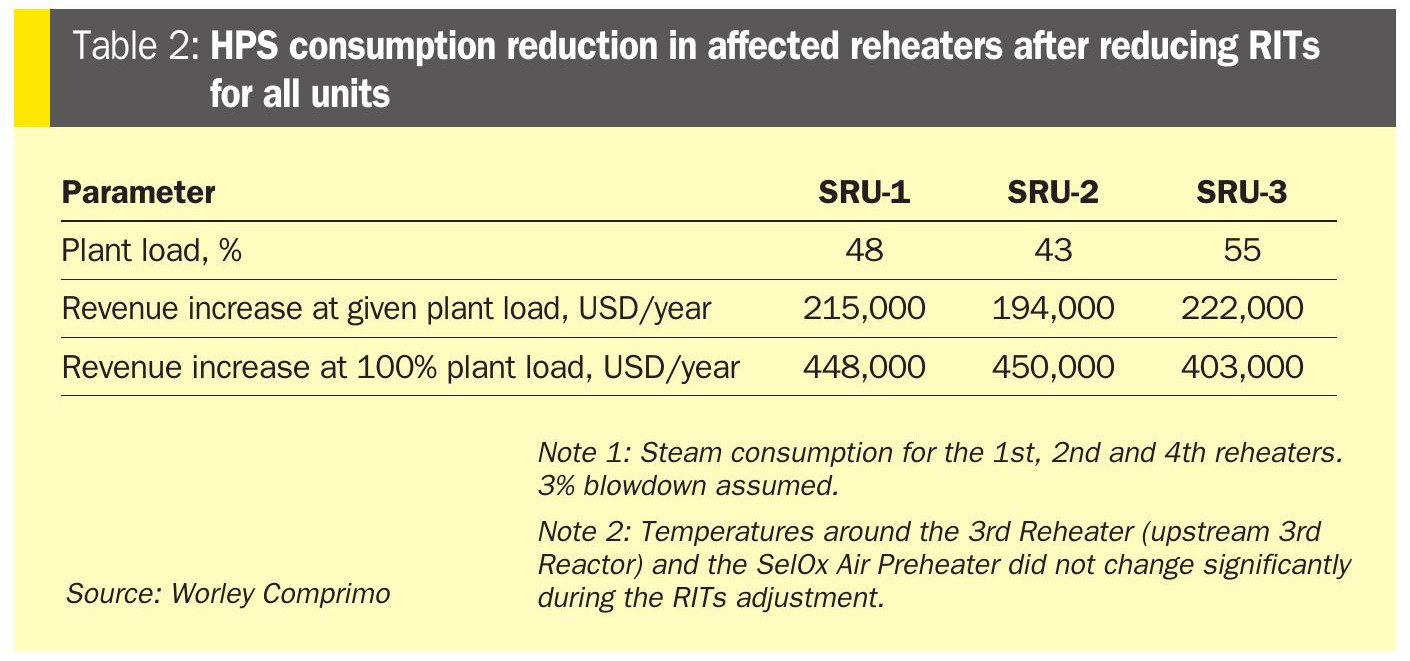

The savings in HPS consumption in the reheaters upstream the 1st, 2nd, and SelOx reactors (1st, 2nd, and 4th reheaters respectively) was estimated based on the actual DCS inlet and outlet temperature values of the process gas through these reheaters, before and after the adjustment in the RITs. These savings are presented in Table 2.

Incinerator optimisation

The incinerator is among the largest energy consumers in an SRU, making it a key candidate for optimisation efforts. The SRU incinerator is followed by a waste heat boiler (WHB) and a superheater for each train, providing superheated steam to steam turbines in the refinery complex.

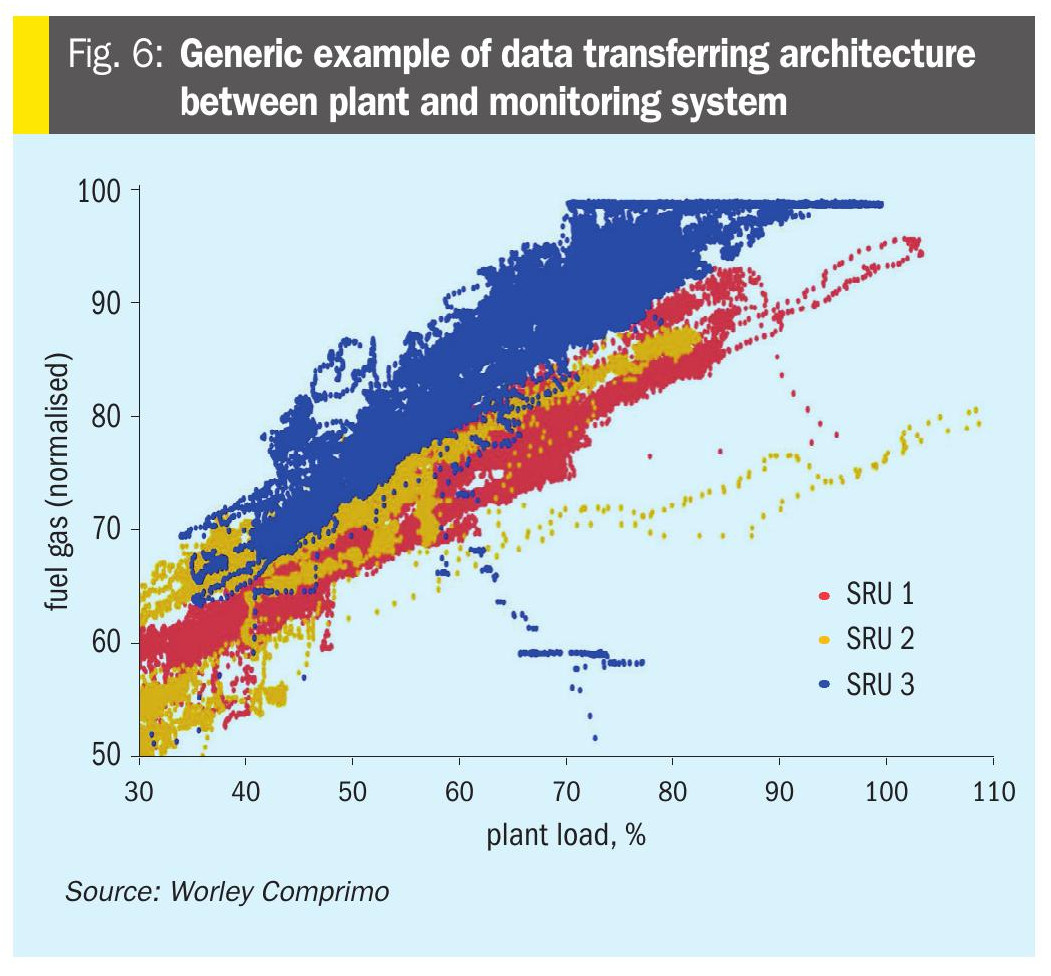

Data analysis revealed inconsistent performance across the three SRUs under similar plant loads, as shown in Fig. 6.

SRU-3 consistently consumed more fuel gas than SRU-1 and SRU-2. Additionally, a fuel gas consumption ceiling for SRU-3 at plant throughputs exceeding 70% was observed, demonstrating that the maximum flow rate for fuel gas had already been reached. Further investigation revealed inadequate control of the combustion air flow rate to the incinerator caused by sticky valves, leading to increased fuel gas consumption to maintain the required incinerator temperature.

Incinerator flue gas temperatures averaged 750°C to 760°C with flue gas oxygen concentrations typically above 5 vol-%, the latter a result of the insufficient control of combustion air flow. Optimising the high oxygen concentration in the stack will lead to reduced fuel gas consumption and, consequently, lower operating cost.

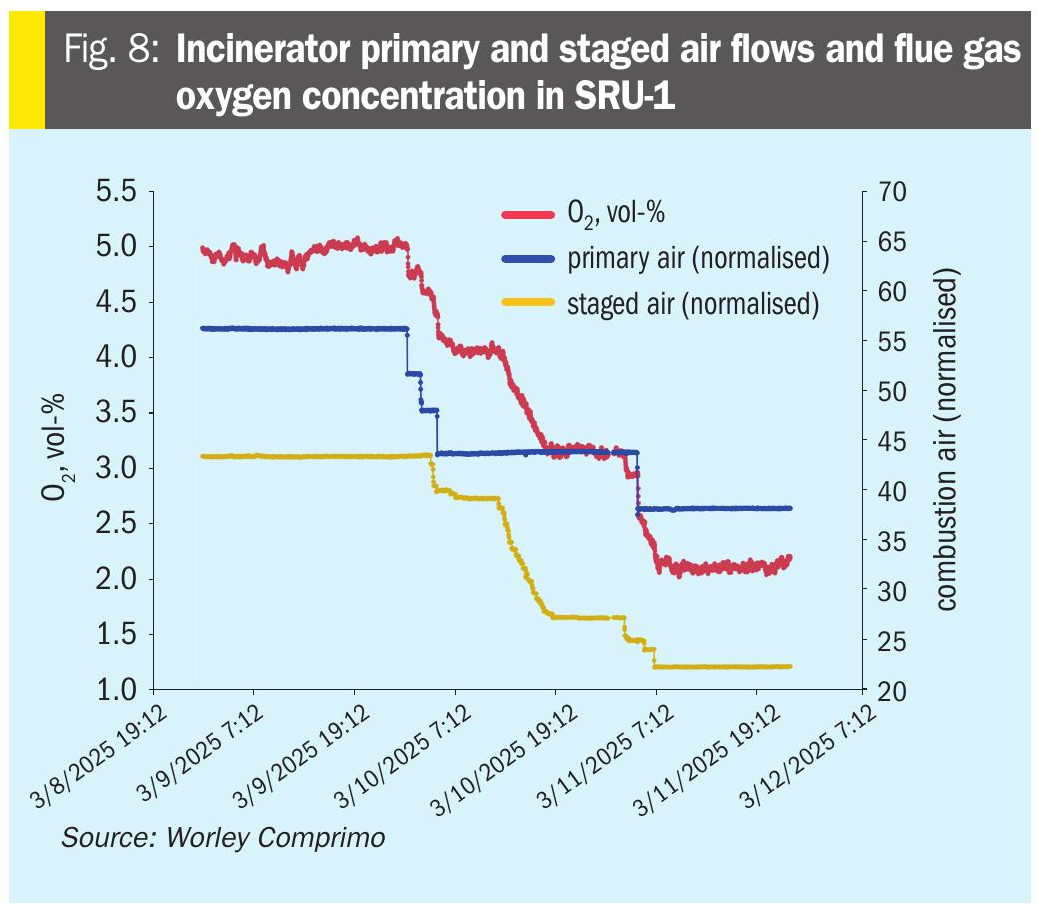

Despite the sticky valves on the primary and staged air system, which challenge precise control of oxygen levels in the flue gas, an optimisation exercise conducted by PRefChem demonstrated notable energy savings opportunities.

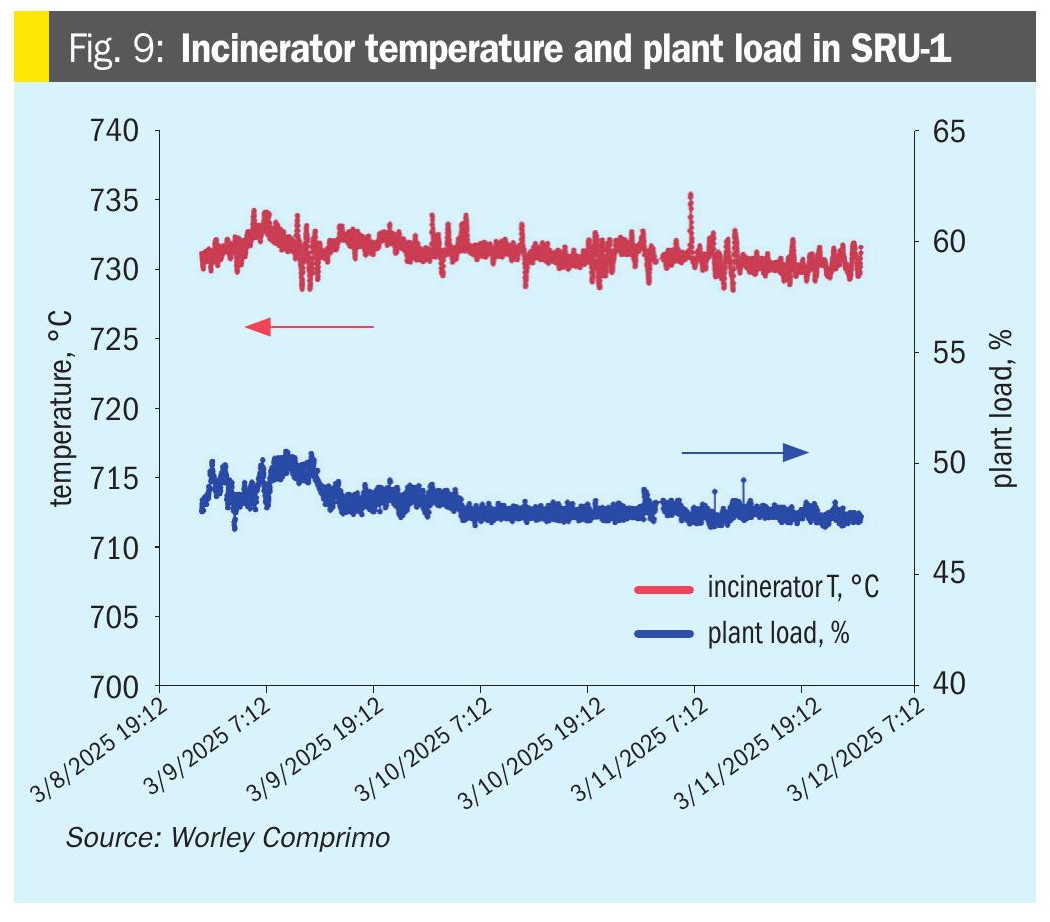

The primary and staged air flows were manipulated to reduce the oxygen content in the flue gas while maintaining the incinerator temperature, without compromising the emission levels at the stack.

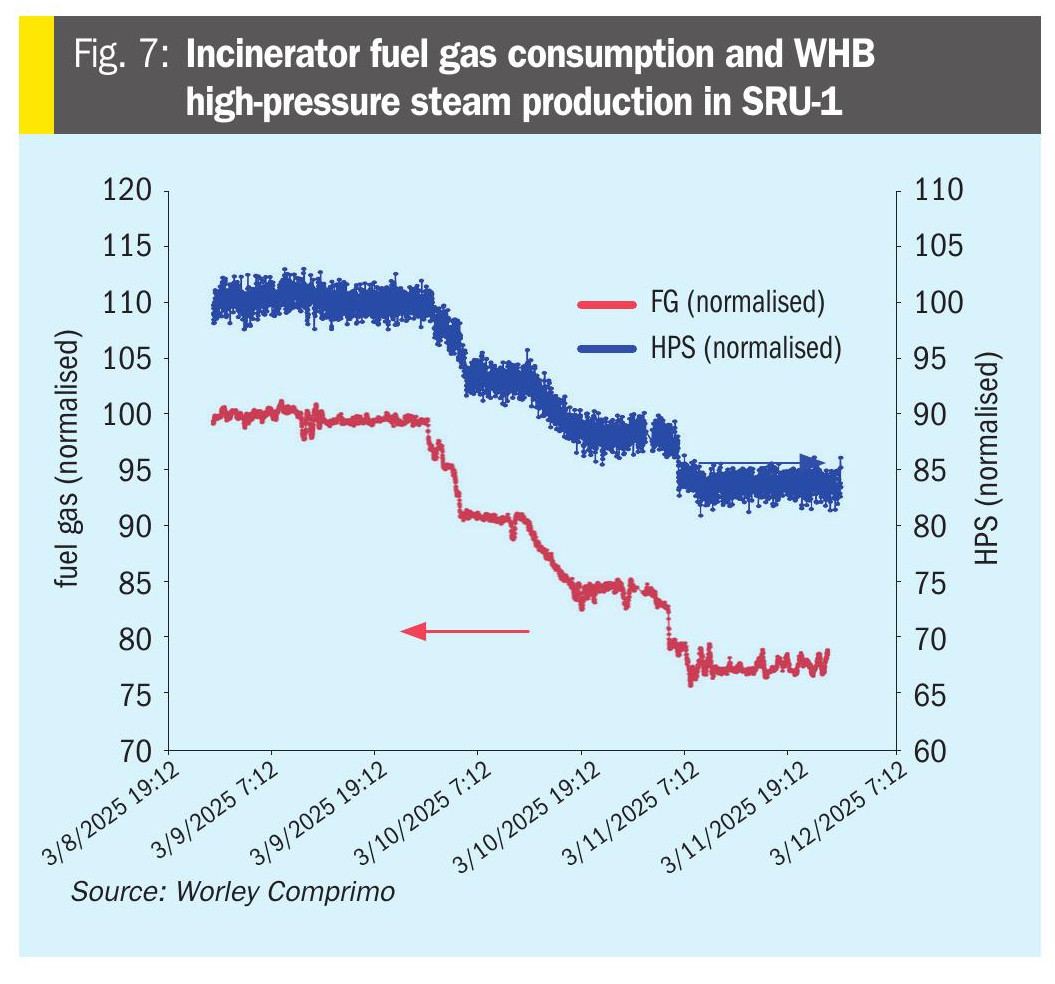

Figs 7 through 9 illustrate the impact on fuel gas consumption and high-pressure steam production in the WHB as primary and staged air flows to the incinerator were gradually lowered during the optimisation test performed for SRU-1.

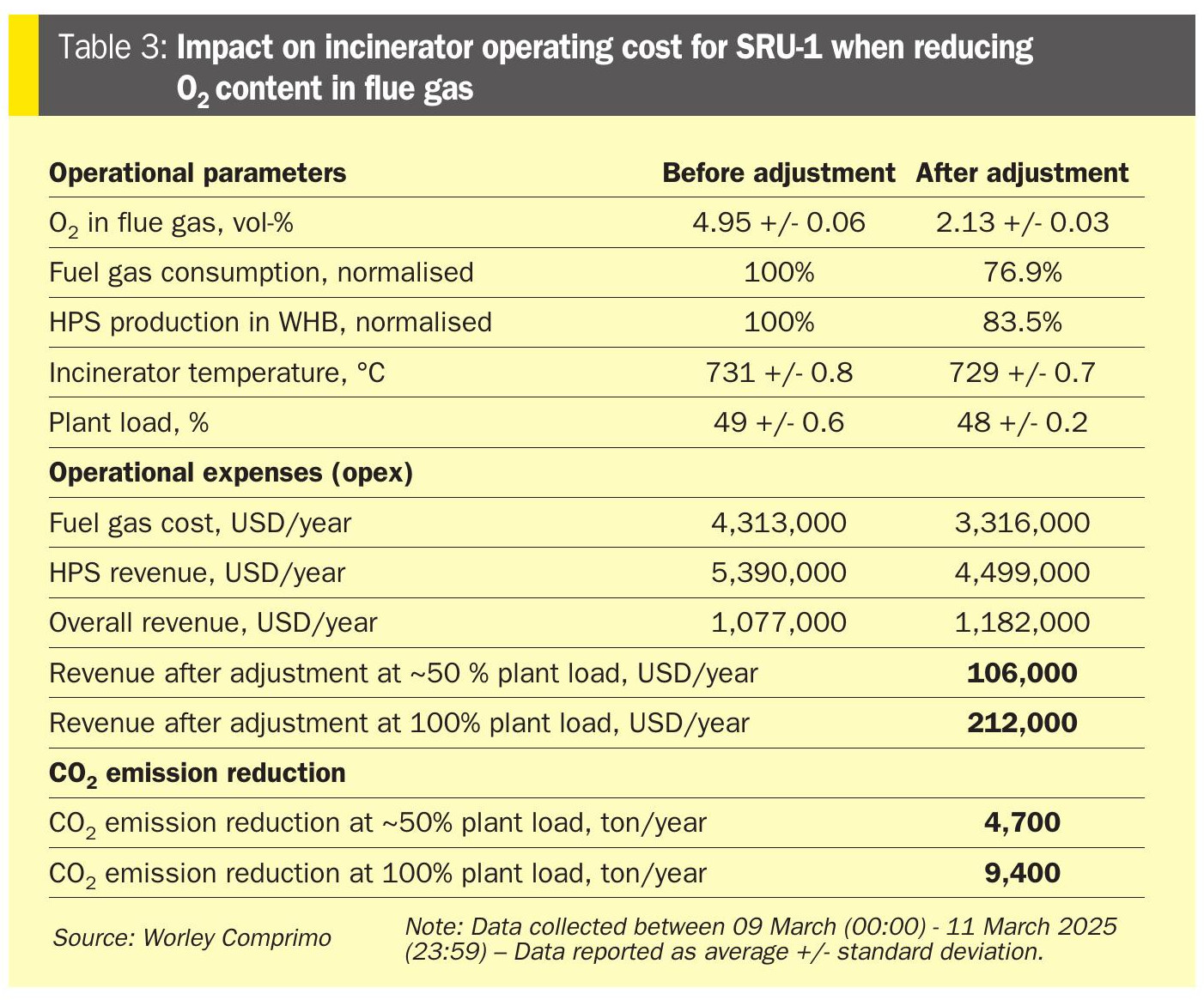

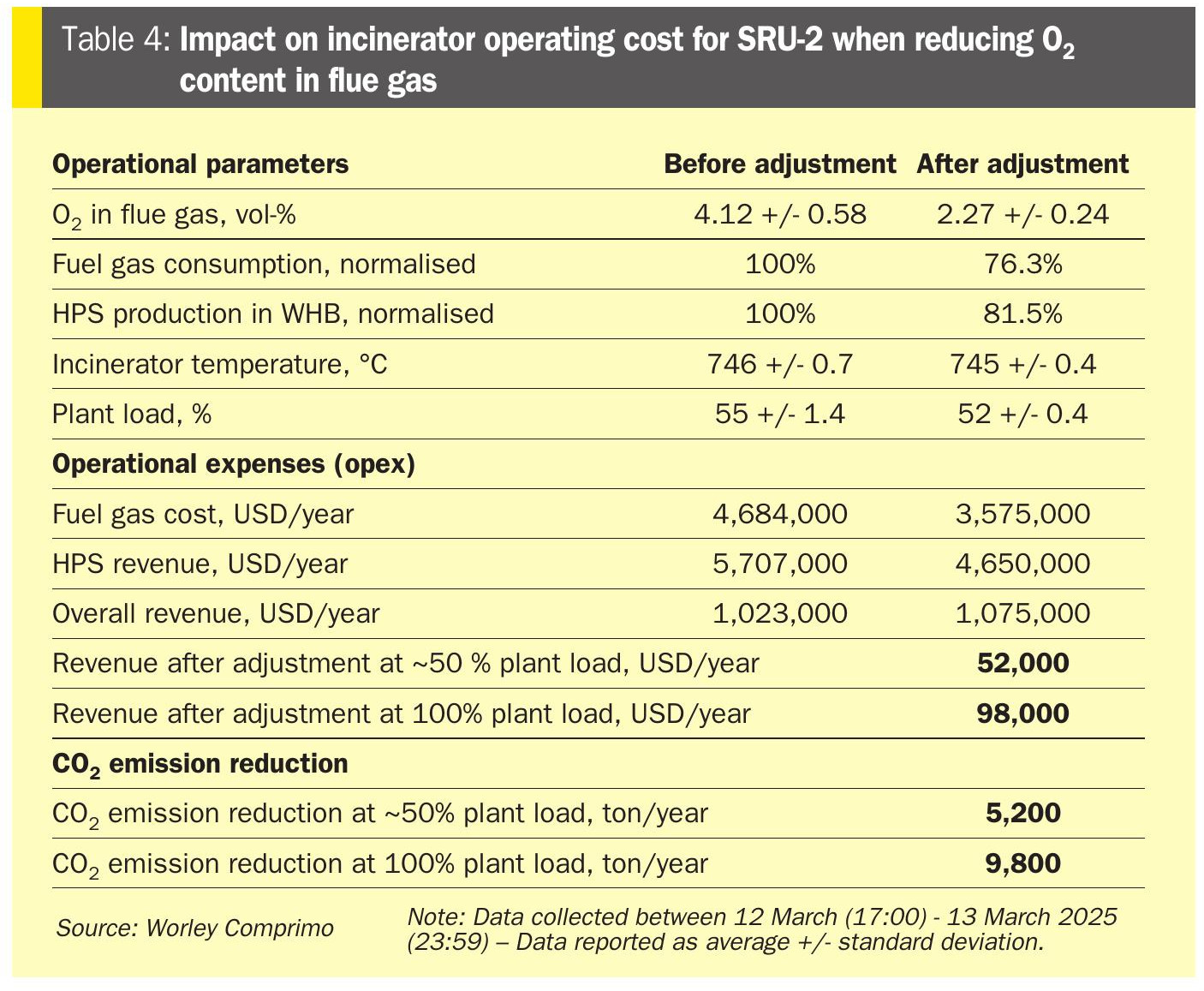

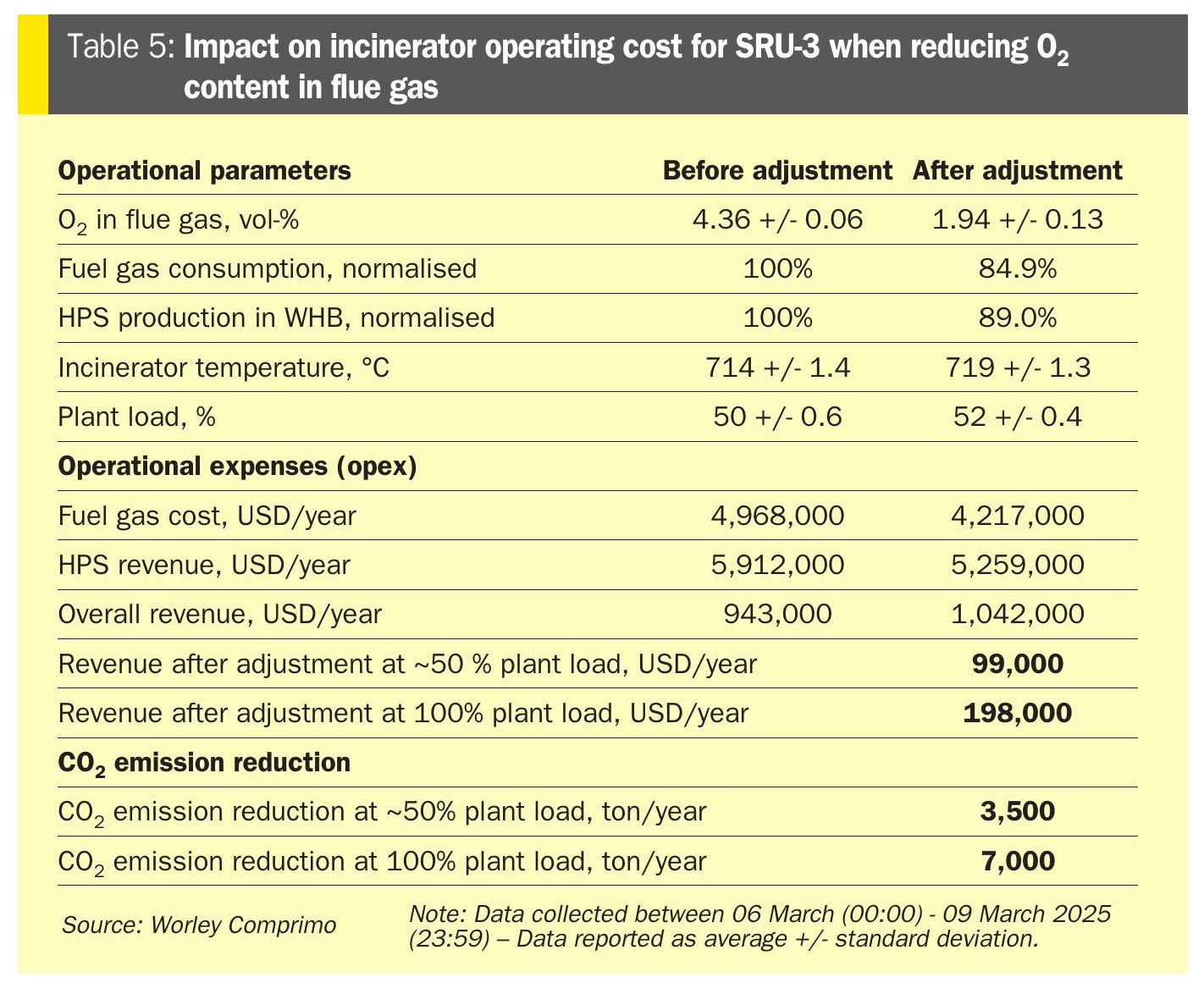

The same optimisation exercise was carried out for SRU-2 and SRU-3. Tables 3 through 5 summarise the resulting impact on utility consumption, steam production, and operating costs for the incinerator and waste heat boiler following flue gas oxygen level optimisation.

Annual cost savings between $52,000 and $106,000 per train were achieved by optimising flue gas oxygen concentration at approximately 50% plant load. The range in savings reflects variability in oxygen concentration adjustments across units, as well as operational challenges associated with precise air valve modulation. PRefChem plans to replace the air valves during the next turnaround to enable more precise air control and deeper optimisation.

In addition to fuel gas savings, a reduction in CO2 emissions is also realised through improved combustion efficiency. This environmental benefit may translate into further economic gains in markets where CO2 emission credits or carbon trading mechanisms are in place.

Conclusions

Implementing advanced monitoring services in SRUs enables proactive performance management and optimisation. By leveraging real-time KPIs, virtual analysers, and data-driven insights from technology specialists, plant engineers and operators can identify inefficiencies, adjust operating conditions, and maintain compliance with environmental requirements.

Multiple energy and operating cost saving opportunities were identified for PRefChem:

- An estimated annual cost savings of approximately $1,300,000 for all three trains combined (at 100% plant load) can be realised by lowering the reactor inlet temperature in the 1st and 2nd Claus reactors, as well as the selective oxidation (SelOx) reactor.

- An estimated annual cost savings of around $500,000 for the three trains combined (at 100% plant load) can be obtained by minimising flue gas oxygen levels in the incinerator. It is possible that even higher savings could be realised once the incinerator combustion air valves are replaced, and a more precise air control is possible.

It is remarkable that these significant savings can be accomplished without any additional investment or changes to the process configuration, and only by adjusting the operating parameters of the plant. This demonstrates the value of assertive and timely technical assistance, and the importance of having a service, such as Comprimo Insight, that enables rapid testing and implementation of such guidance.

With ongoing data collection and analysis, and growing operational trends over longer periods of time, it is expected that other savings opportunities will be identified in the future.

Future initiatives

Looking ahead, continuous monitoring will explore integration with AI and specifically machine learning to enable predictive analytics, anomaly detection, and automatic performance optimisation. Additionally, remote monitoring and cloud-based environments allow centralised oversight of multiple units across different locations.

With the increasing availability of operational data from different plants and unit configurations, standardised benchmarks for key performance indicators and energy consumption are being established, facilitating more effective optimisation of plant operations.

Continuous monitoring services will become a vital component of a proactive strategy for environmental compliance and energy optimisation in SRU plants, as regulations tighten and efficiency demands grow.

Reference

CRU Sulphur + Sulphuric Acid 2024 – Barcelona 2024, article and presentation, “Energy and Cost Optimisation Opportunities in an SRU”, by Jan-Willem Hennipman and Martin Gensor, Worley Comprimo and Slovnaft.

Acknowledgment

Worley Comprimo would like to thank PRefChem for sharing and allowing the use of their plant data in the preparation of this collaborative work. Worley Comprimo also thanks Gokul Sundaramoorthy, Technical Specialist II, in the Sulphur Complex and Acid Gas Treating, Pengerang Refining Company Sdn Bhd (PrefChem Refining) for acting as reviewer and co-author of this article.