Urea technology showcase

Toyo Engineering Corporation, Stamicarbon and Saipem showcase their state-of-the-art urea technologies.

Toyo Engineering Corporation, Stamicarbon and Saipem showcase their state-of-the-art urea technologies.

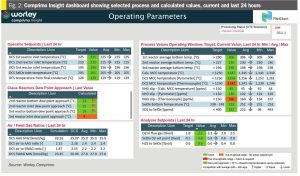

Continuous monitoring of sulphur recovery units (SRUs) has proven to be an excellent tool for energy optimisation and emissions reduction, yielding financial incentives in the form of CO2 credits and sustainability. Even in markets with limited CO2 credits, significant economic benefits can still be realised through reduction in utility consumption, as demonstrated by a recent collaboration between Worley Comprimo and PRefChem in Malaysia.

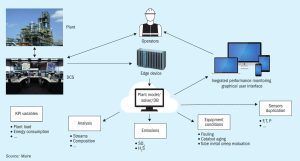

Metso describes how digital solutions can profit from the deep integration of using a digital process twin in sulphuric acid technology, helping to improve operation, monitoring and reporting.

thyssenkrupp Uhde has signed a 5-year framework service agreement with Brunei Fertilizer Industries, aimed at advancing digitalisation and implementing clean technologies in the fertilizer industry. Central to these efforts is the set-up and implementation of a digital twin, which will provide a virtual representation of the plant to enable real-time monitoring, predictive maintenance, and data-driven decision-making. This technology, together with specialized trainings, will allow BFI to enhance operational safety, reduce downtime, and achieve greater energy efficiency.

Metso launches Cu POX leaching process for copper extraction industry - solution maximises copper recovery while reducing environmental impact

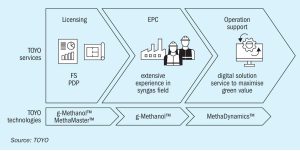

Toyo Engineering Corporation has developed two new digital solutions, MethaMaster™ and MethaDynamics™ , which enhance the operational efficiency of e-methanol production from variable renewable energy.

A report on CRU’s annual Sulphur+Sulphuric Acid Conference, held in Barcelona, in early November.

The ‘golden batch’ refers to stable periods at production plants that consistently generate high quality NPK products at high output. Yara’s Golden Batch digital tool digitises and stores past data from optimal production runs, making these easy to retrieve and implement again in future. Yara’s Marianne Ytterbø provides an overview of this novel digital tool, explains how it was developed, and highlights key benefits.

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

The pursuit of operational excellence requires continuous process monitoring, together with qualified analysis of the collected data. The Digital Process Monitor (DPM) provides a process digital twin which consists of an accurate process plant model that incorporates the licensor’s knowledge and expertise in sulphur recovery technology, thereby providing continuous insights into plant performance. This article provides an overview of the DPM features focusing on the related benefits in terms of overall operational improvements and plant efficiency for the sulphur recovery unit.