Sulphur 420 Sep-Oct 2025

13 October 2025

Sulphur 420 Sep-Oct 2025

13 October 2025

CRU’s annual Sulphur+Sulphuric Acid Expoconference was held from November 3rd to 5th, at The Woodlands, Texas.

Süd-Chemie discusses the importance of pressure drop in a sulphuric acid plant and the many benefits that can be gained from using a guard bed, typically in the first bed of the converter to safeguard the catalyst bed and increase campaign life.

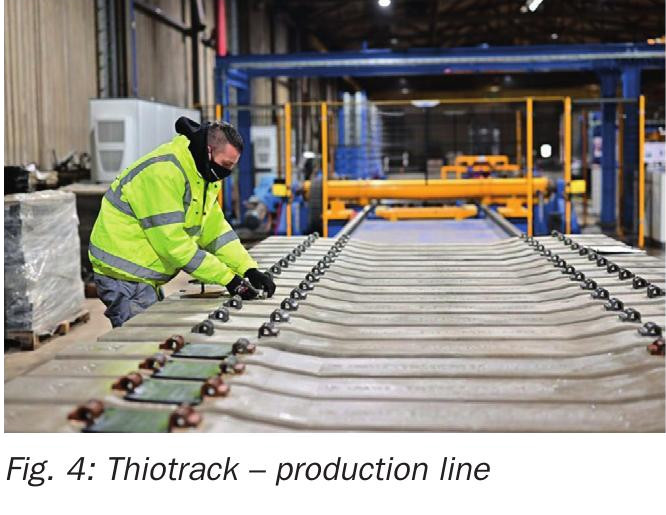

Thiomaterials reports on the key features and successful performance of Thiotrack sulphur concrete sleepers, offering high fatigue endurance with a truly reversible circular binder.

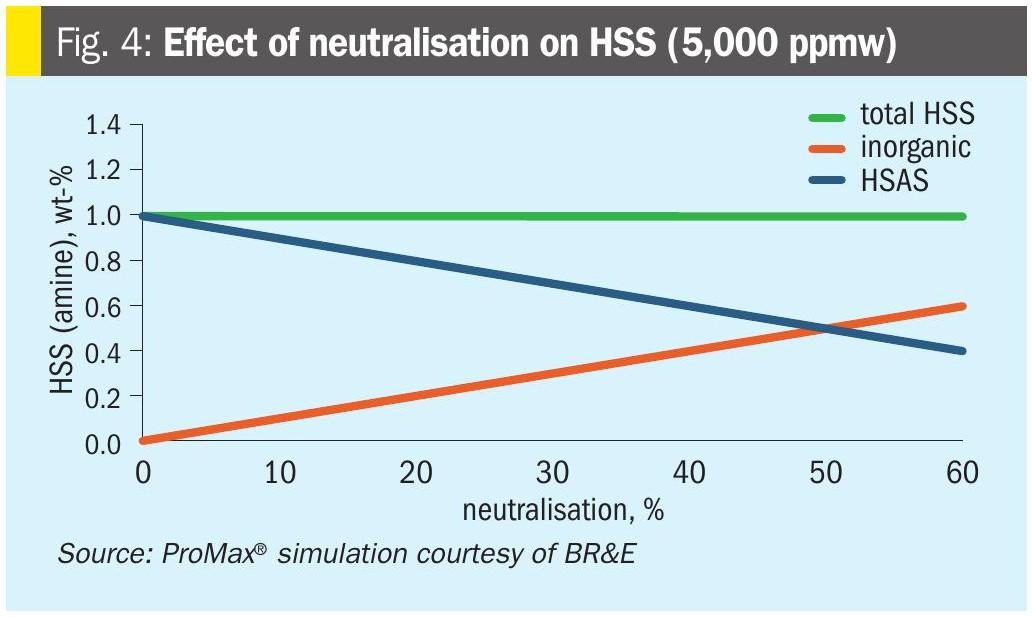

Bryan Research & Engineering (BR&E) and INEOS GAS/SPEC continue their review of neutralisation of heat stable salts. Part 2 focuses on how caustic (NaOH) affects amine chemistry and corrosion and the effects of adding too much NaOH.

Begg Cousland Envirotec reviews different mist eliminator types and some of the operational problems encountered which can be managed by correct installation, targeted cleaning or replacement, and selecting appropriate corrosion-resistant materials.