A new generation of methanol catalysts

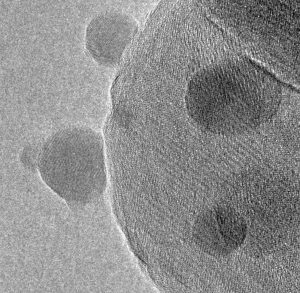

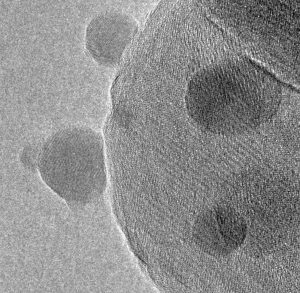

Haldor Topsoe has launched a new methanol synthesis catalyst, MK-181 PRIME, based on new technology developed via close study of copper-zinc interactions on the catalyst surface.

Haldor Topsoe has launched a new methanol synthesis catalyst, MK-181 PRIME, based on new technology developed via close study of copper-zinc interactions on the catalyst surface.

Methanex has said that, in light of the uncertainty in the global economy from the Covid-19 pandemic, it will defer approximately $500 million of previously announced capital spending on its $1.4 billion Geismar 3 methanol project for up to 18 months. Geismar 3, which is intended to eventually produce 1.8 million t/a of methanol, will be placed on temporary “care and maintenance” for up to 18 months, enabling the company to complete the project when market conditions improve. Methanex says it will spend $100 million in Q1 2020 and a further $200 million from April 1, 2020 to September 30, 2021 on the project, the majority of which is spending that occurred or was committed during Q1 2020. This is approximately $500 million lower than the $800 million that was expected to be spent over that same period. Construction activity and procurement of non-critical equipment and bulk materials will be suspended until market conditions allow the Geismar 3 project to restart.

Olefins production from methanol, particularly in China, has come to dominate the methanol market over the past few years. However, environmental and market concerns complicate the outlook there.

Digitalisation and the analysis of big data are playing an increasing role in fertilizer production. Innovative digital and cloud-based services are being offered by a range of technology companies, including Casale, tkIS, Topsoe and TOYO.

Charlotte Hebebrand, Director General of the International Fertilizer Industry Association (IFA), will end her term with the organisation on May 1st. IFA’s Senior Director of the Agriculture Service, Patrick Heffer, will serve as interim Director General as of 1 May, until a new permanent Director General can be proposed by IFA’s Board of Directors and approved by the membership at the organisation’s General Meeting, with the aim of having a new person in place by July.

Clariant has announced that Stephan Lynen will be appointed chief financial officer (CFO) of the company as of April 1st, 2020. Lynen is currently head of the Clariant’s Additives business unit, and has served with the company for more than 20 years in various international general management and business roles. He will succeed Patrick Jany who will be leaving to pursue a career opportunity outside of Clariant as CFO of A.P. Moller-Maersk, a global leader in shipping services.

The Global Gas Flaring Reduction Partnership (GGFR) is a World Bank sponsored programme to end wasteful and CO2 - intensive flaring of natural gas from oil production and stranded shale wells, and has been looking to small-scale methanol and GTL projects as a way of utilising this gas for productive ends.

New ammonia and urea plants in Nigeria and Ethiopia are part of a wave of new capacity in Sub-Saharan Africa, and may help pull up regional demand from its current low base level.

At the Nitrogen+Syngas Conference 2020, held in The Hague, Netherlands, Haldor Topsoe launched its new TITAN ™ series of steam reforming catalysts. The company says that the new series, which consists of the RC-67 TITAN and RK-500 TITAN catalysts, offers improved performance and longer catalyst lifetime thanks to the hibonite-rich composition. The addition of titanium promoters adds exceptional mechanical strength while a seven-hole cylindrical shape yields both a very low pressure drop and a high surface area. Pressure drop build-ups in syngas plants can cause unscheduled downtime and cost millions of dollars, while thermal instability during operation can lead to operational risk and reduce plant lifetime. Topsoe says that the catalysts can mitigate these risks, ensuring lower operating costs, increased profit margins, and reduced energy usage.

This year’s Nitrogen + Syngas conference was held from 17-19 February in The Hague, Netherlands.