Sounding the price klaxon

The war in Ukraine has caused 9,000 civilian deaths and created 5.7 million refugees. If this immense and spiralling human tragedy was not enough, the unprecedented shock inflicted on commodity markets continues to unfold.

The war in Ukraine has caused 9,000 civilian deaths and created 5.7 million refugees. If this immense and spiralling human tragedy was not enough, the unprecedented shock inflicted on commodity markets continues to unfold.

More than 300 delegates from over 130 companies and 29 countries gathered for CRU’s Phosphates 2022 conference, 7-9 March.

Liquid fertilizers are emerging as a high growth, multibillion dollar market. Their growing use is linked to trends such as no-till farming and the greater adoption of precision agriculture. Leading producers and products are highlighted.

We profile leading suppliers of tailor-made pumps and pipes to the phosphates and sulphur industries.

Erosion and corrosion are two of the biggest challenges faced by equipment used in phosphate fertilizer production. This harsh operating environment requires exceptionally well-designed pumps made from sophisticated and robust construction materials. Hani Tello of ITT Rheinhütte and Harvinder Bhabra of ITT Goulds Pumps outline the range of options.

Heat recovery systems at sulphuric acid plants have been providing carbon-free energy for decades now and continue to improve. There is also potential to combine the clean power generated at acid plants with hydrogen production from water electrolysis. This could provide the basis for green fertilizer production.

Certain fertilizer prices are likely to remain above $1,000/t well into 2023, according to Moody’s.

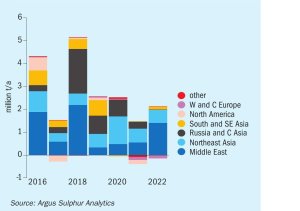

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

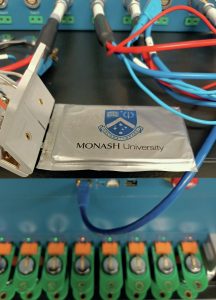

Researchers from Australia’s Monash University say that they have created a new generation of lithium-sulphur batteries which could provide a cheaper, cleaner and faster-charging energy storage solution that outlasts lithium-ion alternatives and is rechargeable hundreds of times without failing. The team has creating a new interlayer which allows for exceptionally fast lithium transfer, as well as an improvement in the performance and lifetime of the batteries.

Most inspection personnel are familiar with the symptoms of process-related issues; however, they often lack an understanding of the root causes of water-related issues. In this article L. Huchler of MarTech Systems and E. Nasato of Nasato Consulting provide insight about early warning signs of common water-related failures in steam generators and sulphur condensers, proactive monitoring practices, practical operating strategies, options for corrective actions, reminders about robust water-side design and reminders about the challenges of prematurely destroying evidence by prioritising cleaning over diagnostic efforts during turnaround activities.