Unintended consequences?

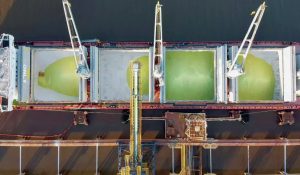

The modern sulphur industry is in effect a response to the environmental problems created by the presence of sulphur compounds in oil and gas, and the consequent release of sulphur dioxide when they are burned. The tens of millions of tonnes extracted, formed, traded and used for sulphuric acid production every year would otherwise be entering the atmosphere and causing health issues, especially in major cities, or returning as acid rain. One of the most recent step changes in sulphur recovery has come from the extension of rules on sulphur content of fuels that have been commonplace for road vehicles for many years into the maritime transport sphere. The International Maritime Organisation has mandated a reduction in sulphur content of bunker fuels to 0.5% worldwide, and 0.1% in busy shipping regions that have become designated emissions control areas (ECAs). Because bunker fuels were made from refinery residues, they often had high concentrations of sulphur in them; the limit before 2020 was 3.5%. As a result, a recent paper by two climate scientists calculates that global SO2 emissions have dropped by as much as 10% since 2020 because of the IMO limits. Given that atmospheric sulphur dioxide is responsible for an estimated 20-90,000 preventable deaths per year, this is surely a good thing.