Urea technology showcase

Toyo Engineering Corporation, Stamicarbon and Saipem showcase their state-of-the-art urea technologies.

Toyo Engineering Corporation, Stamicarbon and Saipem showcase their state-of-the-art urea technologies.

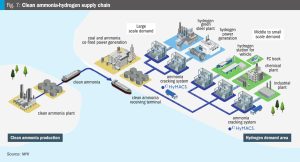

Mitsubishi Heavy Industries is developing a low temperature ammonia cracking technology (HyMACS™ ) that leverages exhaust heat from existing sources, such as boilers, steam turbines, engines, and heating furnaces. This innovative approach, which also includes the development of more efficient membrane separation technology using molecular sieves for hydrogen purification, is designed to offer a more sustainable, reliable and cost-effective pathway towards hydrogen production.

For six decades, Chemetics has been a pioneering force in the sulphuric acid design and equipment industry, consistently introducing groundbreaking technologies that have revolutionised the field by optimising the methodology in which chemicals are produced. This year, Chemetics celebrates its 60-year anniversary as one of the leading designers, direct equipment suppliers and fabricators that has modernised the sulphuric acid industry of today. This article dives into Chemetics’ rich history and key innovations that have shaped and moulded the industry.

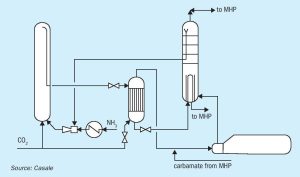

We highlight recent production advances and innovations in nitrogen fertilizer production from Casale and Stamicarbon, two global leaders in process technology.

Transporting sulphur as a dry bulk solid can lead to it breaking into small particles which create dust. Over the years, various forming processes have been developed to try and minimise dust formation and produce the strongest, most resilient formed sulphur particles.

As more focus extends to a circular economy, there are industry wide discussions on whether future global sulphur demand will be challenged by the energy transition and decarbonisation. Hannes Storch, Collin Bartlett and Marcus Runkel of Metso discuss how the recycling of pyrite tailings could address some of these issues.

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

Waste heat recovery in the potash industry is now possible thanks to the availability or robust and reliable heat pipe heat exchangers (HPHEs). Igor Makarenko , Solex Thermal Science, explains how HPHE technology can help potash producers reduce their primary energy consumption and cut their CO 2 emissions.

PT Petrokimia Gresik detail an inventive redesign of their economiser, a critical component in sulphuric acid production, focusing on energy efficiency, decarbonisation, process optimisation, and equipment durability.

Alfa Laval reports on a case study of a sulphuric acid plant in Northwest China that is looking to capture its low-grade heat for re-use and to significantly reduce the amount of fossil fuels used in production.