Sulphur 409 Nov-Dec 2023

30 November 2023

Seeking out energy in sulphuric acid plants

CASE STUDY

Seeking out energy in sulphuric acid plants

A sulphuric acid plant in Northwest China is looking to capture its low-grade heat for re-use. With the support of Alfa Laval’s semi-welded plate heat exchangers and energy recovery expertise, in winter, all of the recovered low-grade heat could be put back into their system with 30% being used in production and the remaining 70% going to heating. During the summer, 14% of the energy that is no longer needed for indoor heating could be used to preheat boiler feedwater. This would enable them to significantly reduce the amount of fossil fuels used in production, without redesigning their entire factory footprint.

Baiyin city is the core area of the Greater Lanzhou Economic Zone and is a sub-centre of the Lanbai Economic Circle, which means that a lot of its infrastructure is connected to the district heating zone in northern China. With current energy demands, Baiyin city uses up its full quota of district heating within six months every year and must rely on traditional coal heating to fill the gap. But in a world where we are all trying to move away from fossil fuels, the government and enterprises are actively looking for solutions that will help them do more with less.

Hunting for excess heat

Driven by the Chinese government’s dual-carbon policy, metallurgical acid manufacturing enterprises have made heat recovery a standard procedure. Today, Alfa Laval has already cooperated with five smelter companies in China, using this low-temperature heat recovery technology.

But, China is not the only country looking to clean up existing infrastructure with heat reuse. Alfa Laval’s Low-Temperature Heat Recovery System has been incorporated on a global scale and can be found in Sweden, Finland, the UK, Germany, India, and many other countries.

This forms part of Alfa Laval’s mission to decarbonise and transform existing traditional systems with energy efficient solutions. The goal is to support customers as they reduce their energy consumption and limit the amount of carbon that enters the atmosphere each year.

In the case of a sulphuric acid plant in Baiyin city, it has already taken important steps to improve energy efficiency within its production facilities. In fact, Alfa Laval has been supporting it with advanced plate heat exchanger technology that can capture excess heat for reuse in production since 2012. In a process where the plant can produce 300,000 tonnes of cathode copper and 1.1 million tonnes of sulphuric acid (calculated as 100% H2 SO4 ) every year, the high and medium temperatures can easily be recovered using a boiler to generate steam for power generation and production. Despite this, the volume of excess heat that can be captured for reuse still falls short of the overall heating demands of the whole plant, especially over winter. It is therefore in urgent need of finding new ways to boost energy efficiency in its sulphuric acid production.

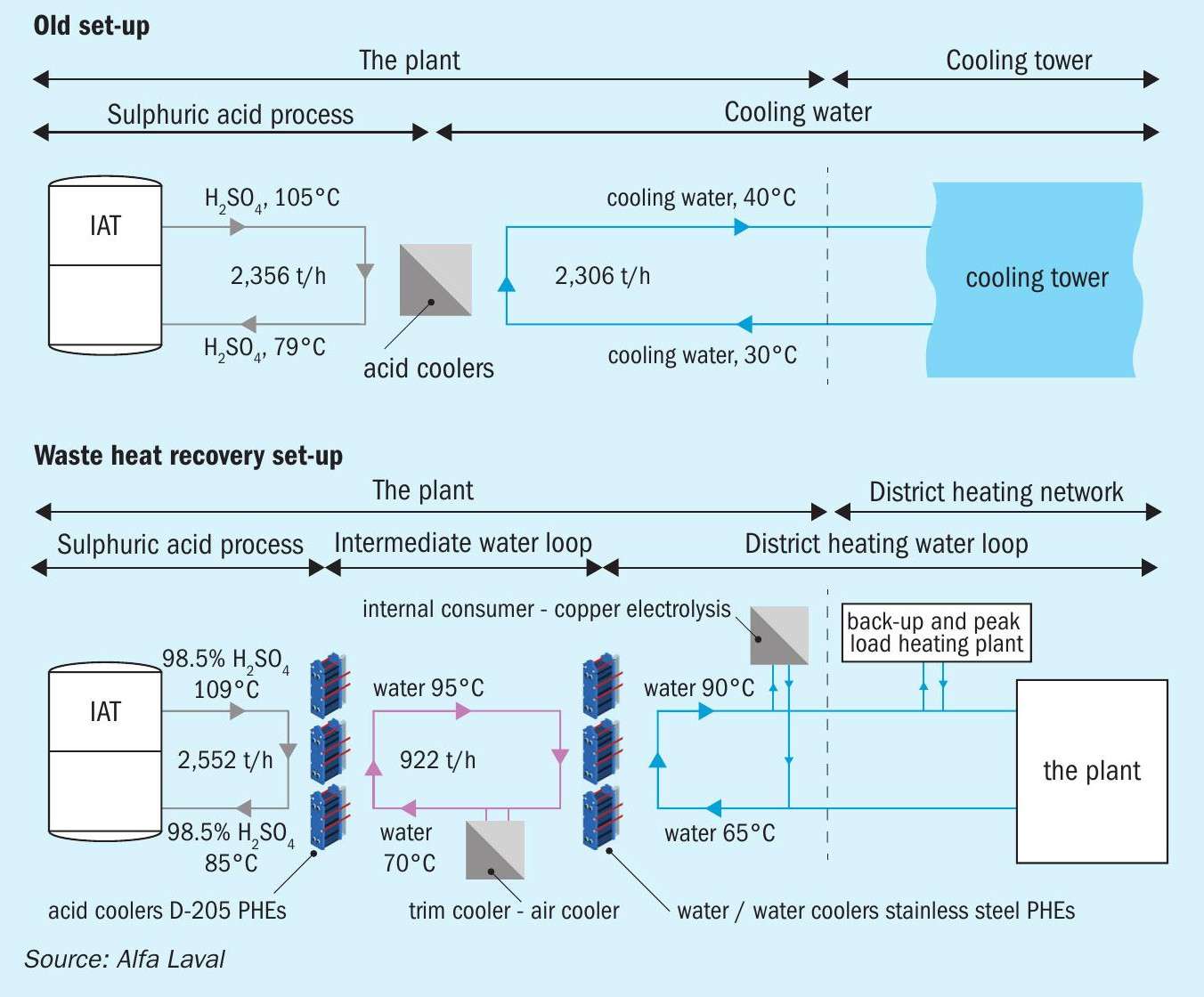

In traditional acid production, a large amount of low-grade heat (heat temperature below 100°C) is generated in the sulphuric acid absorption tower. But because of the extremely close temperature difference between the cold and hot sides, traditional shell-and-tube heat exchangers cannot recover this low-grade heat. In other words, this excess heat ends up discarded in cooling water instead of being put to effective use.

Capturing low-grade heat

With Alfa Laval’s efficient semi-welded plate heat exchanger (SW-PHE) assembly and unique Hastelloy D-205™ plate technology, the customer could have a system that recovers heat from the intermediate absorption tower cooler in the drying and adsorption section of their sulphuric acid production and generates hot water for the copper electrolyte heating in their electrolysis workshop. In addition, this excess heat generated hot water could also be used for pure water preheating, to cool their workshop, and even replace partial low-pressure steam when heating the factory in winter.

In this case, two Alfa Laval plate heat exchangers made of Hastelloy D-205™ would be the best option, as this nickel-based alloy is particularly resistant to highly concentrated sulphuric acid and elevated temperatures. With over 300 units installed worldwide over many decades, it provides a proven reliable solution for their heavy-duty fluid handling requirements.

However, the application scope of D-205 material has strict requirements. For the best possible results, it is necessary to adjust the process according to each situation. With service centres worldwide, Alfa Laval’s sales and service teams coordinate, supply professional support, and follow up on all their products promptly to provide the best customer experience.

With this solution, the heat recovered from the intermediate absorption tower is 26,820 kW, which is the same as reducing 5 bar (a) low-pressure steam consumption by 45.82 t/h. This means that in winter, all the recovered heat can be reused in the system. In this case, 13.75 t/h (30%) is used in the production, while the remaining 32.07 t/h (70%) is used for heating in the heating station. During the summer, when there is no need for building heating, 14% of the 32.07 t/h is used in the pure water station and the rest is ready and available to be used where needed.

Sustainable and profitable investment

Besides financial and environmental benefits, Alfa Laval’s Low-Temperature Heat Recovery System also comes with the following advantages:

- a return on investment within 11 to 13 months;

- less cooling water is needed for drying and adsorption circulation in sulphuric acid production and no need to redesign the gas boiler;

- implementation is easy and won’t affect any existing equipment or systems.

- In Phase I of applying the Alfa Laval Low-temperature Heat Recovery System, the customer has already seen the following environmental benefits:

- they recovered 153,296 MWh of excess heat, enough to heat up 12,000 homes in Europe for a year;

- they reduced their steam consumption by 262,062 t/a

- they reduced their carbon dioxide emissions by 46,922 t/a

- they reduced their overall power consumption by 46,639 MWh per year.