Begg Cousland – more than 70 years in the making

Fertilizer International interviews Graeme Cousland, Managing Director, and Martyn Dean, Sales Director, Begg Cousland Envirotec Limited.

Fertilizer International interviews Graeme Cousland, Managing Director, and Martyn Dean, Sales Director, Begg Cousland Envirotec Limited.

Rotary coolers remain a popular choice with fertilizer producers, explains Shane Le Capitaine of FEECO International, thanks to their ability to meet the industry’s rigorous demands.

Igor Makarenko of Solex Thermal Science reviews the main equipment options for fertilizer cooling and their relative merits.

Fertilizer International presents a global round-up of phosphate rock, phosphoric acid and finished phosphates projects.

Sulphur Experts outline the steps required to determine optimised SRU incinerator operating conditions. Although a proper determination of the ideal SRU incinerator operating conditions for any given facility is complicated by a combination of inconsistent permitting standards and poor understanding of the role of the SRU incinerator, the payoff for incinerator optimisation is a significant decrease in natural gas usage with corresponding savings in operating costs, a decrease in CO2 emissions, and a simultaneous reduction in NOx and SO3 emissions.

We report on the key highlights of the annual SulGas® conference, organised by Three Ten Initiative Technologies LLP,, which took place in Mumbai, India, from January 31 to February 2, 2024.

As the production of renewable methanol continues to scale up, it will provide a long term, carbon-neutral energy solution to different transport sectors. However, the optimum design parameters for green methanol plants are substantially different to natural gas-based methanol plants and pose new challenges to the methanol loop designer. Johnson Matthey discusses the challenges and presents the benefits of the tube cooled converter for e-methanol production.

TOYO has a long history in urea granulation technologies and has recently added two new technologies to its product line-up.

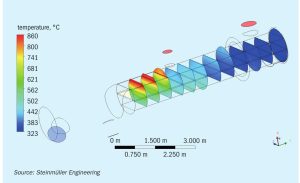

Steinmüller Engineering shares its experiences of applying CFD to re-design the waste heat boiler downstream of the secondary reformer to successfully achieve the desired uniform cross flow across the tube bundle.

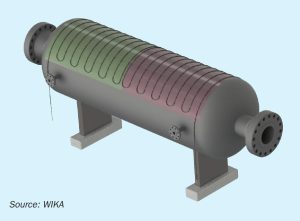

WIKA discusses a novel and easy way to monitor the shell temperature of the Claus thermal reactor using proven technology and highlights the benefits a purge-less thermocouple system for high temperature measurement.