Van Iperen’s Green Switch journey

Van Iperen International is pursuing an ambitious sustainability strategy to cut its carbon footprint by 50%.

Van Iperen International is pursuing an ambitious sustainability strategy to cut its carbon footprint by 50%.

An ammonium nitrate industry geared around producing explosives for the mining sector is now being joined by a major urea project and a number of renewables-based products for export of green ammonia.

Short term supply constraints are dominating acid markets at present, but increasing smelter production across Asia may lead to oversupply in the longer term.

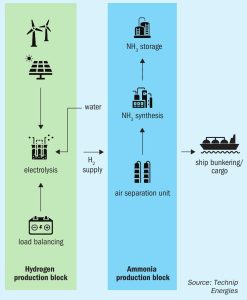

Green ammonia production facilities can be situated in remote areas with access to often fully off-grid renewable power supply. This article examines plant concepts and discusses the challenges and solutions for these plant architectures. Through a case study, an efficient and innovative methodology to compare options and optimise the sizing of the plant is presented. The methodology addresses the intermittency of the power production, the flexibility limits of the main process units, and the costs of investment and operation, using proprietary techno-economic dynamic simulation software, Odyssey.

China’s acid production continues to grow as new smelters come on-stream. But high domestic demand from phosphate production as export restrictions are lifted and a shortage of copper concentrate may limit the potential for acid exports.

We highlight recent innovations, including fertilizers recovered from industrial residues, novel controlled-release coatings, and products that incorporate biological components designed to benefit both crop nutrition and soil heath.

Brazilian phosphate producer Galvani says that it has begun work on its major phosphate expansion in Bahia state, including a new production plant at Ceará, in partnership with Indústrias Nucleares do Brasil (INB). The company aims to reduce Brazil’s northern and northeastern regions’ reliance on imported fertilizers. The first phase includes $133 million of investment, including $76 million for new phosphate mining at Irecê, and $38 million for Luís Eduardo Magalhães factory, also in Bahia. This expansion will take capacity from 600,000 t/a to 1.2 million t/a by 2026. The expansion at Luís Eduardo Industrial Complex includes expansion of sulphuric acid capacity from 165,000 t/a to 250,000 t/a.

The refining industry continues to pivot towards Asia, with knock-on effects for sulphur output.

Desmond Long has been appointed as Chief Executive Officer of BASF Shanshan Battery Materials Co., Ltd effective April 1, 2024. In his new role, Desmond will lead the business management of the company.

China’s drive to build new battery production capacity for electric vehicles and stationary storage is leading to a familiar problem for the Chinese economy; overcapacity.