Sulphur fertilizers – the processes, the products

Mark Brouwer of UreaKnowHow.com reviews the main production options for incorporating sulphur into urea

Mark Brouwer of UreaKnowHow.com reviews the main production options for incorporating sulphur into urea

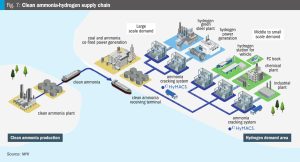

Mitsubishi Heavy Industries is developing a low temperature ammonia cracking technology (HyMACS™ ) that leverages exhaust heat from existing sources, such as boilers, steam turbines, engines, and heating furnaces. This innovative approach, which also includes the development of more efficient membrane separation technology using molecular sieves for hydrogen purification, is designed to offer a more sustainable, reliable and cost-effective pathway towards hydrogen production.

For the first time, K+S is offering farmers low-carbon potash and magnesium fertilizers.

Fertilizer International talks with Jakob Liedberg, the CEO of innovative potassium sulphate producer Cinis Fertilizer.

Common risks of ammonia cracking as a new technology and how these risks can be recognised and mitigated by applying an innovative approach of the technology maturation process is described as seen through the eyes of an end user/investor. Addressing those risks is pivotal to enable end users to choose the best technology for their needs. Albert Lanser of Duiker Clean Technologies discusses some of these risks and how they have been addressed in its novel technology for producing the lowest levelised cost of hydrogen via its unique ammonia cracking process.

NextChem compares KPIs and overall costs to evaluate the performance of several low carbon (blue) hydrogen production technologies. A detailed comparison of SCT-CPO, SMR and ATR technologies is reported.

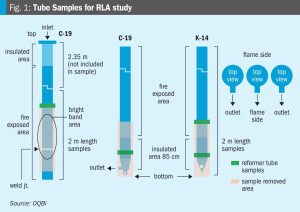

Muhammad Faisal Faraz and Abdullah Al Balushi of OQBi explain how by implementing a series of technical and process improvements, OQBi has successfully extended the lifespan of its reformer tubes by six years beyond the original design life of 100,000 hours.

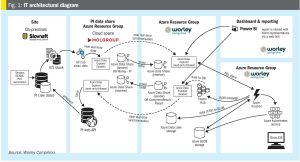

Together with Slovnaft, Worley Comprimo has developed a near real-time monitoring dashboard using data sharing via the Cloud. Using a two-year data set containing minute average data, trends and insights were used to optimise performance. This paper describes the main learnings and improvements with respect to energy optimisation, which supports sustainability targets for Slovnaft.

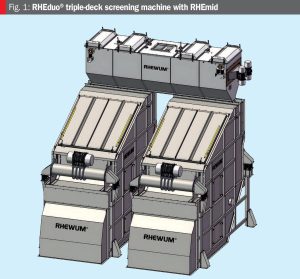

De-bottlenecking is a profitable path for potash producers, as RHEWUM's Tountzer Ramadan and Alexander Krasovsky explain.

PuraLoop is a new fertilizer created from recycled phosphorus. ICL’s Patricia Imas and Lucas van der Saag highlight its main benefits.