China’s phosphate industry

Continuing rationalisation in China’s phosphate industry has been reducing demand for sulphur and sulphuric acid at the same time that the country is producing more of both.

Continuing rationalisation in China’s phosphate industry has been reducing demand for sulphur and sulphuric acid at the same time that the country is producing more of both.

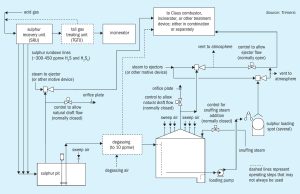

Fires are known to occur in sulphur storage pits and tanks somewhat frequently due to the presence of both flammable material and air, so methods for preventing and extinguishing these fires are critical. D. J. Sachde, K. E. McIntush, C. M. Beitler, and D. L. Mamrosh of Trimeric Corporation review fire suppression methods used in the industry including snuffing/sealing steam, rapid sealing, water mist, and inert gas blanketing. Protective tank design features to reduce the likelihood of a sulphur fire are also reviewed. Benefits and limitations, design considerations, and recommended guidance for suppression and preventative measures are discussed.

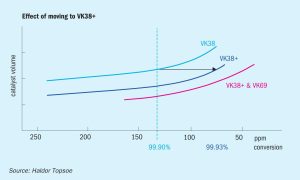

Selecting the right catalysts for the SO2 converter in a sulphuric acid plant has always been about balancing expenses, gains, and compliance. With increasing demands for sustainability and in challenging economic times, operators need to adjust their plants to get even more from less. This has led to market demand for new catalytic solutions that offer better productivity and a lower climate footprint, all at the lowest cost possible. Catalyst design and formulations continue to evolve with Haldor Topsoe, DuPont Clean Technologies and BASF all adding new types of sulphuric acid catalysts to their portfolios.

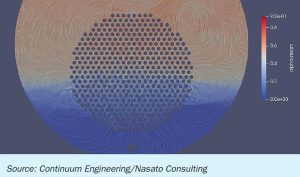

Failure investigations, equipment design and process upgrade projects for SRUs often overlook the impact of water quality. In this article E. Nasat o of Nasato Consulting and L. Huchler of MarTech Systems explore impacts of higher heat transfer rates, control of boiler and condenser water chemistry, conventional equipment design/configurations and monitoring program designs. SRU operators can improve the effectiveness of their failure investigations by implementing a broader, more holistic approach that assesses equipment design, process conditions, operating protocols and water quality issues.

After many years of slow decline, Canadian sulphur exports have begun to rise slightly, but dwindling US markets are seeing a move towards more sulphur forming to expand export opportunities.

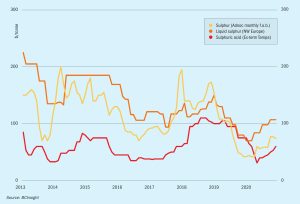

The global pandemic and new wave of lockdowns in some regions continue to pose a level of uncertainty to oil demand and in turn sulphur recovery. There are positive signs in the macro economic picture on the back of the vaccine rollout but significant question marks remain.

A look back at some of the major events of 2020 for the sulphur and sulphuric acid industries, as well as a look forward as to how 2021 might look.

Demand for oil in developed countries was already falling before the coronavirus outbreak, and consumption growth is slowing in the developing world. Peak oil demand may arrive in the next decade. Coupled with more reinjection of sour gas rather than sulphur extraction, could we be seeing falling elemental sulphur production in a decade or so?

Although 2019 had been a volatile year for acid markets, with shutdowns disrupting supply, the coronavirus outbreak wrought even more havoc in 2020, across both supply and demand.

Sulphur reports on this year’s Sour Oil and Gas Advanced Technology (SOGAT) conference, which was run as a virtual event at the end of September 2020.