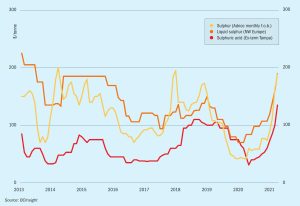

Market Outlook

Major projects to consider in the short term outlook are Barzan in Qatar and the Clean Fuels Project in Kuwait. Combined these would add over 3 million t/a of sulphur capacity.

Major projects to consider in the short term outlook are Barzan in Qatar and the Clean Fuels Project in Kuwait. Combined these would add over 3 million t/a of sulphur capacity.

Although 2020 saw a contraction in GDP by 10% due to the impact of the coronavirus pandemic, the country had been one of the fastest growing of the world’s top 10 economies, with growth of 8.3% in 2016, although this had slowed to 4.1% in 2019. Its population is growing, and it is due to become the most populous country in the world by 2027 according to UN figures, with total population reaching 1.64 billion by 2050. The country thus continues to require more food, leading to rising sulphur/sulphuric acid consumption for the phosphate industry on the one hand, although increasing vehicle use and growth in domestic refining is also leading to some additional sulphur production.

With declining ore grade feed to a metallurgical smelting process comes an increase in impurity load in the gas cleaning/acid process chain. K. Hasselwander, L. Skilling and C. Bartlett of Metso Outotec discuss a range of process solutions and how to maintain high productivity while keeping costs in check.

This year’s SulGas conference, covering sulphur recovery and gas treating with a special focus on India and southeast Asia, was run as a virtual event from February 1st to 3rd 2021.

The profound demand shock caused by Covid-related lockdowns has had a major impact upon the refining industry. Run rates have been at low levels in North America and Europe, and a new wave of rationalisation is under way, at the same time that capacity continues to grow in Asia. Will this spur diversification into petrochemicals and low carbon options for Atlantic basin refiners?

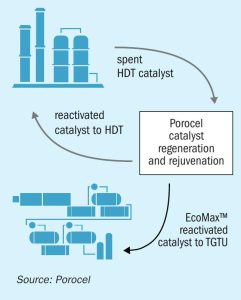

EcoMax™ tail gas catalysts offer a sustainable and cost effective choice for tail gas catalysts. They are made from spent hydroprocessing catalysts, which reduces the environmental and socioeconomic impacts of sourcing fresh cobalt and molybdenum and therefore supports operators’ sustainability goals. B. Visioli of Porocel (a part of Evonik) discusses the benefits of catalyst reuse from hydroprocessing for tail gas treating.

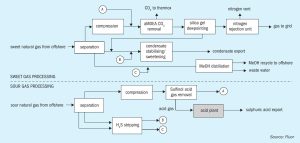

M. Baerends of Fluor reports on the conception, engineering, construction, commissioning and start-up of a new sulphuric acid plant that replaced an existing acid plant at a European sour gas processing terminal. This highly complex gas processing facility handles sour gas from an off-shore field, containing H2 S that must be removed to meet transmission grid specifications. Various issues encountered, their resolution by the joint owner, Fluor and Topsoe team, and plant operating results are discussed.

Wet sulphuric acid technology when used as tail gas treatment for a Claus unit, or in place of a Claus unit with amine-based tail gas unit, brings many benefits if there is a market for the sulphuric acid and steam. A new alternative is to have a WSA unit in combination with a Claus unit and to recycle the acid to the Claus unit for higher sulphur recovery efficiency.

Sour gas processing presents a number of unique challenges, especially at high levels of hydrogen sulphide and carbon dioxide content.

Euro Support’s new generation, titania-based low temperature tail gas catalyst shows a marked robustness to the start-up procedure compared to its common alumina-based counterparts. Dr B. Hereijgers of Euro Support discusses the promising lab results.