Price Trends

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Most inspection personnel are familiar with the symptoms of process-related issues; however, they often lack an understanding of the root causes of water-related issues. In this article L. Huchler of MarTech Systems and E. Nasato of Nasato Consulting provide insight about early warning signs of common water-related failures in steam generators and sulphur condensers, proactive monitoring practices, practical operating strategies, options for corrective actions, reminders about robust water-side design and reminders about the challenges of prematurely destroying evidence by prioritising cleaning over diagnostic efforts during turnaround activities.

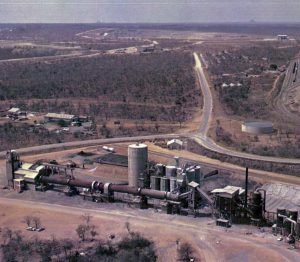

This is the 400th issue of Sulphur magazine, now in its 69th year. From its beginnings as the Quarterly Bulletin of the Sulphur Exploration Syndicate, it remains the only magazine dedicated to both the sulphur and sulphuric acid industries.

The economic conversion of phosphogypsum waste into a valuable product has been pursued for decades. Although phosphogypsum is still generally disposed of as waste, industry attitudes are changing and greater use of phosphogypsum will be expected in a circular economy.

A new fully automated process has been developed that combines real time H2 S readings from an H2 S analyser and Q2 Technologies’ proprietary scavenger chemistry to treat high H2 S crude oil on demand. The process provides an efficient and effective way to administer the chemical product to avoid overtreating or undertreating. In some cases, the end user is seeing greater than 50% savings. It is a unique confluence of technology including IoT, advanced chemistry, and oil and gas personnel incentivised to demonstrate continuous improvement.

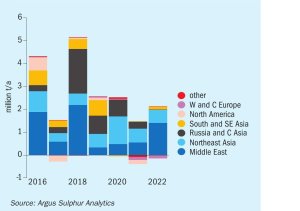

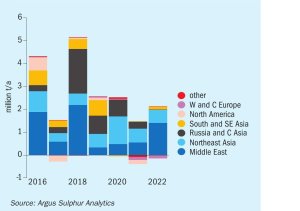

Russia’s invasion of Ukraine has turned the sulphur market on its head, potentially removing several million tonnes of supply from Russia and Kazakhstan and sending prices skyrocketing.

US refiners have upgraded to take advantage of generally cheaper, sourer crude feeds. However, a ban on oil imports from Russia may make that harder to come by.

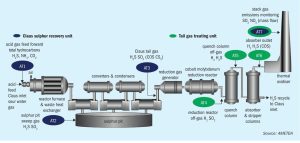

Jochen Geiger of AMETEK Process Instruments reviews SRU process analyser standards, how to choose the right instruments, what to watch out for when selecting the point of installation, responsibilities for the analysers after installation, and how to make best use of the information provided by these analysers. Potential upset conditions and how analysers can help us to understand and mitigate them are also discussed.

The ongoing conflict in Russia-Ukraine remains a key focus for the market in the months ahead. It is unclear whether buyers that are currently doing so will permanently choose non-Russian sulphur sources, but trade flow changes are expected to persist through the rest of 2022.

The Sulphur Community is set to reconvene in Abu Dhabi. CRU and UniverSUL Consulting, with the support of ADNOC, are hosting a new live event, Middle East Sulphur Conference (MEScon), which will take place at the Rosewood Abu Dhabi from 24-26 May 2022.