Methanol demand for olefins production

Olefins production from methanol, particularly in China, has come to dominate the methanol market over the past few years. However, environmental and market concerns complicate the outlook there.

Olefins production from methanol, particularly in China, has come to dominate the methanol market over the past few years. However, environmental and market concerns complicate the outlook there.

As existing facilities grow older, service requirements increase. Equipment needs to be low maintenance and back in operation quickly after service and repair. Technology licensors are expanding their technical services with new digital tools, using digitalised expertise with real time insights and data driven analytics to boost chemical production and ensure that equipment operates reliably and efficiently, while maintaining product quality.

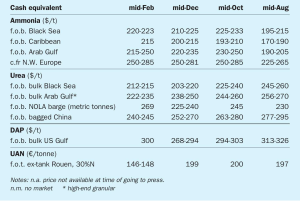

Alistair Wallace, Head of Fertilizer Research, Argus Media, assesses price trends and the market outlook for nitrogen.

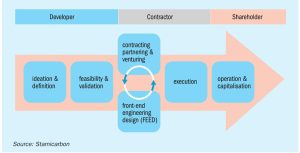

Paving the way for commercially attractive, sustainable, decarbonised fertilizer production, J. Dobrée of Stamicarbon BV discusses the latest developments for nitrate fertilizer production based on renewable feedstocks sourced from solar and wind energy. Stamicarbon has upgraded plant designs used in the past to create a new type of small-scale fertilizer plant capable of producing a product mix that can be adjusted to meet specific local requirements with maximised output value, thereby maintaining a competitive position towards imported products and large-scale producers.

The Global Gas Flaring Reduction Partnership (GGFR) is a World Bank sponsored programme to end wasteful and CO2 - intensive flaring of natural gas from oil production and stranded shale wells, and has been looking to small-scale methanol and GTL projects as a way of utilising this gas for productive ends.

Alistair Wallace, Head of Fertilizer Research, Argus Media, assesses price trends and the market outlook for nitrogen.

Lessons can be learned from the challenges faced during the construction, commissioning and start-up phases of major projects. In this article challenges and experiences are shared from the recent successful commissioning of ammonia and urea plants around the world, including projects in Indonesia, India, Egypt and the Middle East.

New ammonia and urea plants in Nigeria and Ethiopia are part of a wave of new capacity in Sub-Saharan Africa, and may help pull up regional demand from its current low base level.

The impact of coronavirus on both supply and demand continues to provide considerable uncertainty to the market. With much of Hubei province on lockdown, and a corresponding reduction in ammonia demand for DAP production, Chinese imports appear to be down, pushing more ammonia onto the international market and creating generally bearish sentiment.

AmoMax ® -Casale is a new ammonia synthesis catalyst jointly developed by Casale and Clariant. Retaining the same superior resistance to ageing, poisoning and mechanical strength as the well-known wustite-based catalyst, AmoMax ® 10, the new catalyst is significantly more active. C. Berchthold of Clariant and S. Panza of Casale explain the advantages of AmoMax ® -Casale and share the start-up experience of the first commercial reference.