FID expected soon on blue methanol project

Transition Industries has signed a long-term firm natural gas supply contract for the Pacifico Mexinol project in Topolobampo, Sinaloa state with CFEnergía.

Transition Industries has signed a long-term firm natural gas supply contract for the Pacifico Mexinol project in Topolobampo, Sinaloa state with CFEnergía.

The government of Morocco has signed an agreement with the ORNX consortium to advance a $4.5 billion green ammonia project in the southern...

You can listen on demand to this webinar for free which took place on the 4th of March. Just register your details and you will be provided access to the event.

The promise of a global green hydrogen economy is immense, but its realization is hindered by a fundamental challenge: the monumental task of building the necessary infrastructure for production, storage, and transport.

Honeywell and Johnson Matthey have agreed to amend the agreement for Honeywell’s purchase of JM’s Catalyst Technologies business segment. Honeywell’s payment for the business has been reduced from £1.8 billion ($2.43 billion) to £1.325 billion ($1.8 billion), and the completion date for the transaction has been extended to July 21, 2026, with a possible extension […]

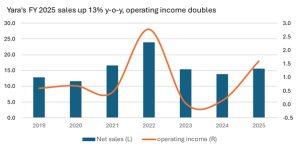

Yara’s full-year earnings (EBITDA) surged to $2.75bn in 2025, driven by stronger nitrogen margins, lower fixed costs and solid volumes.

Grupa Azoty has dismissed its CEO Andrzej Skolmowski after less than one year in the role.

At the CRU Nitrogen + Syngas conference, CRU spoke with Syed Aamir Abbas, Chief Technical Officer at Fauji Fertilizer Company Limited (FFC), about how Pakistan’s fertiliser sector is navigating tightening natural gas availability and what that means for future supply security.

Ballance Agri‑Nutrients and its partners say that the Kapuni Project has reached financial closure, unlocking an integrated renewable electricity and green hydrogen development in ....

Casale and Paralloy Group have signed a strategic Memorandum of Understanding (MoU) at the recent CRU Nitrogen+Syngas 2026 Conference in Barcelona to jointly commercialise ...