Boosting sulphuric acid production with oxygen

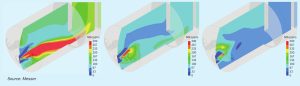

A plant operating a spent acid decomposition furnace as part of its sulphuric acid production facility desired to increase acid production primarily by processing additional spent acid while making minimal modifications to the plant equipment and operations. The Messer solution entailed introducing oxygen in two steps, both as an enrichment to the combustion air and by direct injection into the furnace. The resulting performance improvements exceeded the project objectives for acid production and spent acid decomposition, without increasing NOx emissions. This paper provides a summary of the system start-up and tuning and presents the resulting improvements and lessons learned.