Press Release: Greene Tweed achieves hydrogen compression breakthrough with record-speed composite impeller

Greene Tweed's advancement in hydrogen compression technology sets a record-breaking tip speed to 688 m/s in testing

Greene Tweed's advancement in hydrogen compression technology sets a record-breaking tip speed to 688 m/s in testing

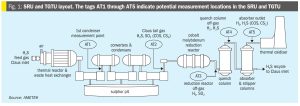

Maximising sulphur recovery in a modified Claus SRU/TGTU requires controlling and monitoring COS and CS2. Leveraging decades of monitoring experience, AMETEK Process Instruments discusses the formation, impact and monitoring of COS and CS2.

Nitricity has secured $50 million in funding and commenced building a liquid fertilizer production plant in Delhi, California.

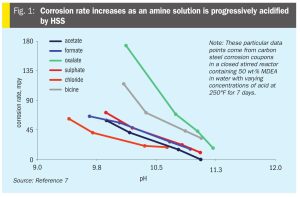

Joel Cantrell of Bryan Research & Engineering and Clay Jones of INEOS GAS/SPEC re-evaluate the historical practice of intentionally adding strong base such as caustic (NaOH) to amine with the purpose of improving performance and reducing corrosion by “neutralising” heat stable amine salts (HSAS) which have accumulated in the amine.

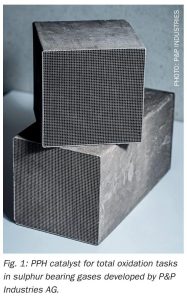

Platinum-promoted honeycomb catalyst bricks offer function as total oxidation catalysts that convert all oxidisable species under appropriate temperature and oxygen conditions. P&P Industries presents a case for a H2S-rich gas stream – relevant to the fibre industry, Claus offgas treatment, and other chemical sectors.

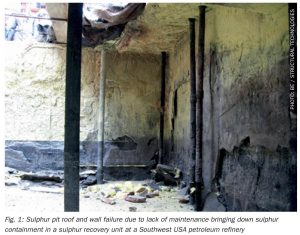

A full sulphur pit turnaround and rehabilitation is typically a once in a lifetime experience for refinery personnel. Specialists in sulphur pit turnarounds, Gavin Palmer of Brindley Engineering, Tom Kline and Bob Hall of Structural Technologies have compiled a database based on multiple sulphur pit turnarounds to identify typical deficiencies in mechanical systems, along with improvements to enhance operability, restore functionality and meet all codes/standards and best practices.

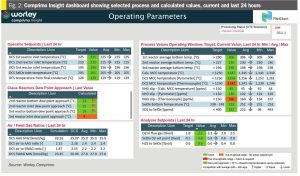

Continuous monitoring of sulphur recovery units (SRUs) has proven to be an excellent tool for energy optimisation and emissions reduction, yielding financial incentives in the form of CO2 credits and sustainability. Even in markets with limited CO2 credits, significant economic benefits can still be realised through reduction in utility consumption, as demonstrated by a recent collaboration between Worley Comprimo and PRefChem in Malaysia.

MHI has successfully completed the Ghorasal Polash Urea Fertilizer Project in Bangladesh - the country’s largest fertilizer complex. Key features of the project include: the KM CDR Process™ that captures CO2 , cuts emissions and boosts urea output; an energyefficient granulation unit using a bulk flow cooler to reduce power demand; and reinforced digital safety management.

The following case study describes a serious incident and the consequences of erroneously mixing nitric acid with hydrochloric acid. In Part 1 we reported on the incident and the causes that led up to the event. In part 2 the impact, recommendations and lessons learned will be discussed.

Advances in cooling technology are providing fertilizer facilities with new options when it comes to upgrading outdated equipment and improving environmental sustainability of their existing operations. Igor Makarenko of Solex Thermal Science explores cooling strategies to improve operational efficiencies while also reducing their energy consumption, greenhouse gas emissions and overall carbon footprint.