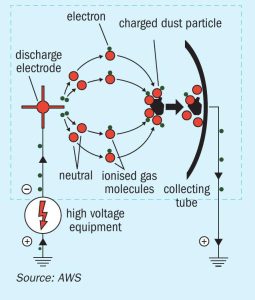

Urea dust scrubbing system with WESP

TOYO has recently introduced new proprietary urea technologies to its technology portfolio including a novel dust scrubbing system with integrated wet electrostatic precipitator (WESP) for ultimate clean-up of granulation or prilling exhaust air, to achieve urea dust emissions of less than 5 mg/Nm3 . Takuhiro Minato of Toyo Engineering Corporation explains how the new system works.