Emissions scrubbing technology

We highlight recent advances in ammonia and dust scrubbing systems for urea plants from Stamicarbon, thyssenkrupp Industrial Solutions and Toyo Engineering Corporation.

We highlight recent advances in ammonia and dust scrubbing systems for urea plants from Stamicarbon, thyssenkrupp Industrial Solutions and Toyo Engineering Corporation.

NOx emissions from chemical processes such as steam methane reforming contribute to air pollution. The chemical industry is required to take steps to lower such emissions. Technology, developed for related industries, can be designed and optimised to reduce NOx emissions from steam methane reformers. Emission control experts can use a combination of modelling and experience to guide plant operators in recommending and designing optimum, sometimes tailor-made solutions. In this article different options are discussed including low NOx burners, selective catalytic reduction, selective non-catalytic reduction and high emissivity ceramic coatings.

In a carbon-constrained world, carbon capture and utilisation or storage (CCUS) installed on a methanol plant is a necessary and feasible solution. The new, patented AdWinMethanol CC® technology, jointly developed by thyssenkrupp Industrial Solutions AG and GasConTec GmbH, integrates carbon capture into large-scale, natural gas-fuelled methanol production to yield a drastically reduced carbon footprint. U. Koss and W. Balthasar of GasConTec and J. Wagner of thyssenkrupp Industrial Solutions discuss how it removes CO 2 emissions in an efficient, cost effective, and environmentally friendly manner, taking advantage of the design features of AdWinMethanol ® .

A. Bhargav and A. Krishnan of Helium Consulting Pvt. Ltd discuss how it is possible to reduce SOx emissions within the existing system setup of an oil refinery or gas plant through detailed analysis, expedited corrective actions and the use of automated algorithms in real-time, by using a digital IIoT solution to monitor, control and optimise.

Malte Plewa, Volker Schmidt, Daniel Ávila and Enrico Rubertus of German development agency GIZ and Dr. Silke Karcher of the German Environment Ministry (BMU) discuss action on climate change from nitric acid production and the Nitric Acid Climate Action Group (NACAG) and its global initiative for mitigating emissions.

thyssenkrupp Industrial Solutions discusses a revamping concept to reduce CO2 emissions by replacing some of the hydrogen in the front end of the ammonia plant with green hydrogen, KBR and Casale report on revamp options to increase the capacity of vintage ammonia plants in the former Soviet Union, Johnson Matthey presents a novel integrated ammonia flowsheet for the production of ammonia, methanol, urea and UFC and Arvos | Schmidtsche Schack discusses the benefits of a new process gas boiler.

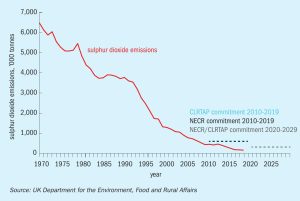

Legislation to control emissions of sulphur dioxide continues to tighten, via vehicle exhausts, and refinery and smelter emissions, leading to increased recovery of both sulphur and sulphur dioxide.

TechnipFMC’s EARTH ® technology, with its structured catalyst jointly developed by TechnipFMC and Clariant, has been proven to be a cost effective way to drastically improve productivity and energy efficiency of the steam reforming process, while reducing the CO 2 footprint per unit hydrogen and syngas product. The technology can be applied in projects to increase the capacity of ammonia and methanol plants and allows significant reduction of greenhouse gas emissions. S. Walspurger of Technip Benelux B.V. and S. Gebert of Clariant GmbH report on the EARTH ® technology and its applications.

Falling costs for production of hydrogen by electrolysis are encouraging more serious consideration of using recovered carbon dioxide as a feedstock for chemicals and even fuels production.

Fugitive dust emissions during the handling and storage of formed sulphur can result in negative environmental impacts and under specific conditions result in an explosion hazard. Enersul has developed a dust suppression system specifically targeted at controlling sulphur dust particles. The Enersul SafeFoam Transfer System (STS) reduces sulphur fines at critical transfer points throughout any sulphur handling system, resulting in a significantly safer and more environmentally friendly sulphur handling system.