CO2 recovery options in sulphur plants

CO2 emission abatement strategies have become increasingly important as the world strives to combat global climate change. RATE discusses carbon capture options available for sulphur recovery units.

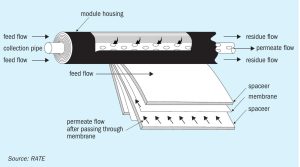

CO2 emission abatement strategies have become increasingly important as the world strives to combat global climate change. RATE discusses carbon capture options available for sulphur recovery units.

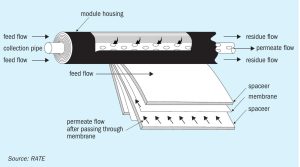

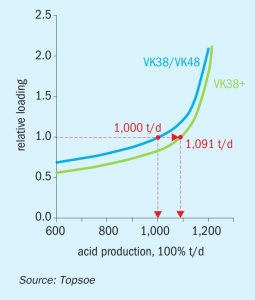

With energy prices skyrocketing, sulphuric acid plant operators face a heightened challenge to improve plant efficiency. Martin Alvarez from Topsoe discusses how the company’s new high-activity catalyst, VK38+, can help acid plants maximise energy efficiency to secure important economic benefits while simultaneously reducing their carbon footprint.

Industry focus on technologies to reduce the carbon intensity of ammonia and methanol production has been intensifying. In this article thyssenkrupp Uhde, Proton Ventures, Toyo Engineering Corporation, Stamicarbon, BD Energy Systems and KBR report on some of their latest technology developments towards decarbonisation.

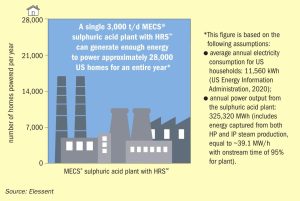

By recovering waste heat as process steam or electrical energy, technologies are available that can help sulphuric acid plants meet their energy goals. Colin Shore of Elessent Clean Technologies discusses how MECS® HRS™ technology can offer a sustainable solution to enhance sulphuric acid plant performance, while lowering its carbon emissions.

The recently-published IEA Ammonia Technology Roadmap sets out a future pathway for decarbonising the nitrogen industry. New technology options for low-carbon ammonia production are emerging and project activity is on the rise.

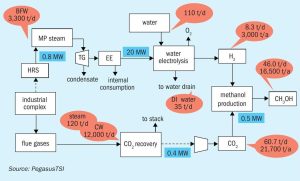

Heat recovery systems at sulphuric acid plants have been providing carbon-free energy for decades now and continue to improve. There is also potential to combine the clean power generated at acid plants with hydrogen production from water electrolysis. This could provide the basis for green fertilizer production.

Erika Niino-Esser of thyssenkrupp Industrial Solutions explains the importance of thyssenkrupp’s technologies for sustainable hydrogen and ammonia value chains in the global energy transition, and how they are contributing to a climate-neutral world. Several novel green hydrogen projects are also highlighted.

The COP-26 summit in Glasgow last year signed into force new rules on carbon emissions trading which may gradually start to see carbon pricing spread worldwide, with knock-on effects on emissions intensive industries like ammonia and methanol.

As all industries come under pressure to decarbonise, are there ways to reduce the carbon footprint of sulphur recovery operations?

Ricardo L. Sepulveda of PegasusTSI reviews options to decrease the CO2 footprint of a fertilizer industrial complex and illustrates the technical and economic feasibility of utilising clean energy from a sulphuric acid plant in a fertilizer complex to produce green hydrogen, which in turn can be used to produce green methanol or green ammonia.