CF ships first low-carbon cargo to Europe

CF Industries has made its first shipment of certified low-carbon ammonia to Europe.

CF Industries has made its first shipment of certified low-carbon ammonia to Europe.

Nitricity has secured $50 million in funding and commenced building a liquid fertilizer production plant in Delhi, California.

Mitsubishi Heavy Industries has successfully delivered compressor trains for the Beaumont ammonia project in Texas.

Sustainability consultancy ERM has been has been tasked with developing a low-carbon roadmap for the potash and phosphate industry.

Globally, operational renewable ammonia projects have exceeded one gigawatt (GW) of installed electrolyser capacity for the first time. Kevin Rouwenhorst of the Ammonia Energy Association (AEA) provides an overview of well-advanced projects and the associated technology options for ammonia synthesis.

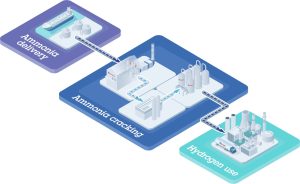

Air Liquide is developing a new ammonia cracking technology based on its proven steam methane reforming (including SMRX™ ) technology, which introduces a heat exchange concept to cut energy use, lower environmental impact, and potentially eliminate steam export. Leveraging extensive SMR design expertise, a robust R&D programme, and an industrialscale NH3 cracking pilot plant, it aims to rapidly mature all technology blocks and deliver safe, reliable, and customisable lowcarbon hydrogen solutions to meet growing demand.

Ammonia is poised to grow beyond fertilizers into energy transition roles, with lowcarbon pathways via blue ammonia and green ammonia, supported by existing logistics and market structures. To support this transition, Stamicarbon is expanding its NX STAMI™ ammonia technologies – with a mediumpressure design for large, CCUSintegrated plants and a highpressure design for small/ medium renewable projects – demonstrating efficiency, reliability, and cost advantages.

ATOME has signed a definitive offtake agreement with Yara International for its Villeta project in Paraguay.

Could demand mandates help the build the market for green fertilizers – by placing mandatory purchasing requirements on large-scale end users?

Delegates gathered in Morocco in September for AFA's Technical Conference. We present selected highlights from this year’s event.