Sulphur 422 Jan-Feb 2026

28 January 2026

Prolonging campaign life with guard catalyst

SULPHURIC ACID CATALYST

Prolonging campaign life with guard catalyst

M. Shanmuga Sundaram and Sreekanth of Süd-Chemie discuss the importance of pressure drop in a sulphuric acid plant and the many benefits that can be gained from using a guard bed, typically in the first bed of the converter to safeguard the catalyst bed and increase campaign life.

The pressure drop (differential pressure, DP) in a sulphuric acid plant is a measure of the pressure difference across components and equipment. Regular monitoring helps operators track performance and detect and troubleshoot problems early.

In an acid plant, each process step and piece of equipment has a designed pressure drop that typically increases over time for several reasons, including accumulation of foreign material, equipment damage, and scaling. The rate of increase in pressure drop indicates the condition of the equipment or process step. Pressure drop is monitored at two levels: the initial (baseline) pressure drop – measured under clean conditions and often compared with the design value – and its subsequent evolution. Although decreases in pressure drop from the original level can occur in specific cases, this article focuses on increases, which create many operational challenges and bottlenecks for the acid plant operator.

Pressure drop across each catalyst bed in the SO2 converter reflects the performance of that bed. The rate at which pressure drop evolves in the catalyst beds is a critical factor when planning catalyst turnarounds for replacement or for screening and replenishment.

Importance of pressure drop

An optimum pressure drop indicates efficient gas flow through the catalyst bed, ensuring proper contact between reactants and the catalyst surface. A high DP in the converter reduces conversion efficiency, increases energy consumption, increases mechanical stress on catalyst pellets, and lowers productivity. Many factors can cause an elevated DP in the converter; common causes include:

- accumulation of dust or other foreign material on the top of the catalyst bed;

- plugging of the catalyst bed bottom grids or support screens;

- unfavourable catalyst properties;

- converter geometry;

- improper gas distribution;

- catalyst deterioration;

- catalyst poisoning;

- excessive catalyst loading;

- gas flow rates higher than the design rate;

- deterioration of bed-support inerts.

Similarly, a low differential DP in the converter also reduces conversion efficiency, which can increase stack emissions and lower productivity. Common causes of low DP include:

- gas channelling;

- insufficient catalyst volume;

- increased voidage in the catalyst bed due to foreign material;

- catalyst size and shape;

- poor gas distribution;

- oversized converter diameter (relative to flow);

- gas flow rates below design.

Converter design and DP

Converter design plays a critical role in achieving the optimal differential pressure. Key design considerations that affect DP include:

Material selection: Choose construction materials that resist deformation and maintain dimensional integrity under operating conditions.

Superficial gas velocity: Superficial velocity depends on the free cross-sectional area (converter dimensions). Velocity is a primary factor in pressure drop across the catalyst bed.

Gas flow pattern: Careful design of gas flow paths and distribution systems helps ensure even flow through the bed and prevents channelling.

Bottom-grid design: A well-designed bottom grid optimises gas flow, minimises unnecessary obstructions, reduces total pressure drop, and lowers the rate at which DP increases by preventing grid plugging.

Catalyst vs pressure drop

The size and shape of catalyst significantly affect both reaction performance and pressure drop in a reactor.

Catalyst size: Smaller catalyst particles generally show higher activity because of increased external surface area, but they also cause higher pressure drop due to reduced voidage and greater flow resistance.

Catalyst shape: Optimising catalyst shape requires balancing performance and pressure drop. For example, ribbed ring pellets can reduce pressure drop compared with cylindrical pellets of the same size.

Selecting the correct catalyst size and shape based on superficial gas velocity is critical because it determines residence time and the contact surface area available to reactants. Ribbed ring pellets of the same size as cylindrical pellets can offer up to 50% lower pressure drop.

Pressure drop increases with gas flow rate and decreases with greater catalyst surface area and higher void volume. While catalyst density and shape influence pressure drop, void fraction is a primary controlling factor.

Quantity: The optimum catalyst quantity ensures the required conversion and overall productivity.

Reliable pressure drop measurements

All analysis begins with reliable data; accurate pressure drop data is the foundation for sound decision-making, trend identification, and early detection of issues that could cause unplanned stoppages.

The pressure drop profile is a key health indicator for the acid plant; a stable, well-maintained profile indicates efficient operation and good process control. Close monitoring of pressure drop is essential: ensure the pressure points are well maintained with periodic cleaning, calibration of the sensors and cross-validation of the readings with a manometer or calibrated portable gauges. Perform thorough cleaning of pressure points during major shutdowns.

Why pressure drop evolves

The cause of DP evolution can be related to the catalyst, process and the equipment.

Catalyst-related factors

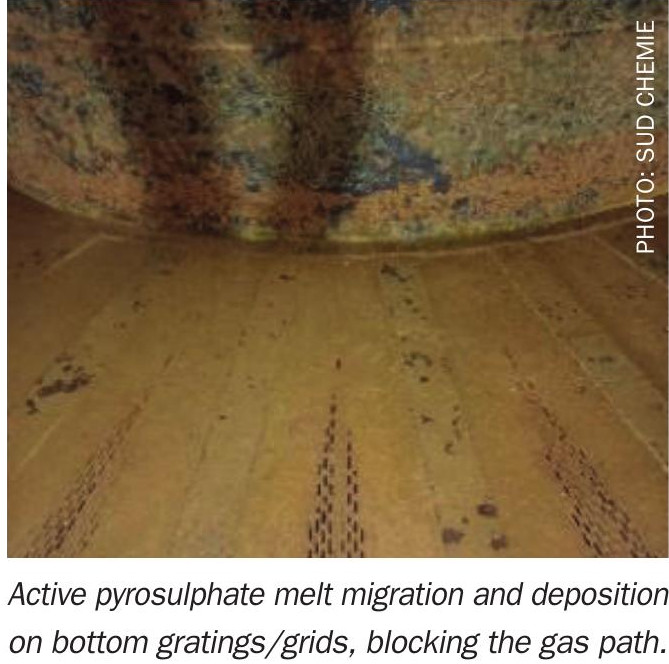

- Incorrect chemical composition can cause active pyrosulphate melt migration and deposition on bottom gratings/ grids, blocking the gas path.

- Catalyst aging reduces physical integrity (sintering), increasing DP.

- Thermal stress and sintering compromise catalyst integrity and raise DP.

- Low crush strength causes particle breakage, generating dust and reducing void fraction.

- Catalyst shape and size affect surface area and void fraction, affecting pressure drop.

- Frictional losses during gas flow depend on internal pore dimensions.

Process-related factors

- Impurities originating from the sulphur feed or air stream can increase DP.

- Acid carryover into the catalyst bed degrades performance and raises DP.

- Moisture ingress (e.g., from boiler or economiser leaks) affects DP.

- Higher gas flow rates increase pressure drop.

- Inadequate cleaning, screening, or catalyst-handling practices accelerate DP evolution.

- Chemical poisoning (e.g., arsenic, fluoride) negatively affects catalyst behaviour.

- Operating conditions such as elevated temperature or higher inlet SO2 concentrations influence DP.

Equipment-related factors

- Grid failure can cause gas channelling, resulting in reduced DP.

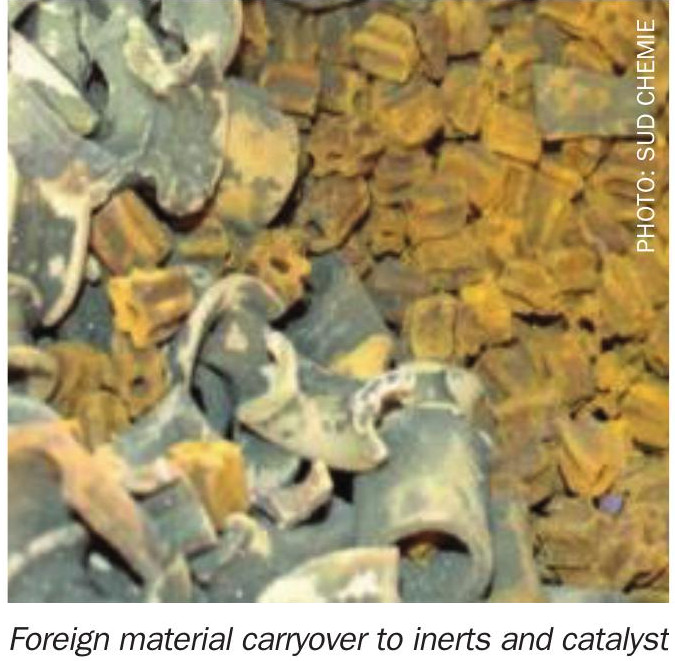

- Refractory breakdown can introduce refractory material into the beds, increasing DP.

- Mist eliminator failure can cause acid mist carryover into the converter bed.

- Steam/water equipment failures can cause moisture carryover into the converter bed.

Impact of catalyst physical properties on DP

Physical integrity: Physical integrity (mechanical strength) is a key property of catalyst pellets. Sharp edges or brittle pellets are more prone to breakage, lowering integrity. Prolonged exposure to acid mist or moisture accelerates deterioration and sintering.

Attrition: Low attrition rates reduce screening losses and extend catalyst life. Attrition depends on operating conditions, catalyst physical properties, and handling during screening.

Breakage: Pellet breakage increases pressure drop by reducing void fraction. Causes include improper handling, low crush strength, and exposure to high temperatures.

Sources of contaminants leading to DP evolution

Feed gas: Pressure drop across converter beds often results from contaminants carried in the feed gas. Clean feed gas extends catalyst life, slows DP evolution and extends catalyst screening intervals. Feed sources such as metallurgical smelting, spent-acid regeneration, and wet-gas sulphuric acid plants may contain heavy metals, organic matter, and particulate dust that should be removed upstream. In practice, gas-cleaning efficiency is sometimes suboptimal, allowing contaminants to reach the catalyst bed and cause mechanical and chemical deactivation in addition to increasing DP.

Sulphur feed: The form and purity of sulphur feed matter. Solid sulphur requires melting and filtration to reduce ash carryover. Molten sulphur from refineries is typically higher purity and contains fewer contaminants.

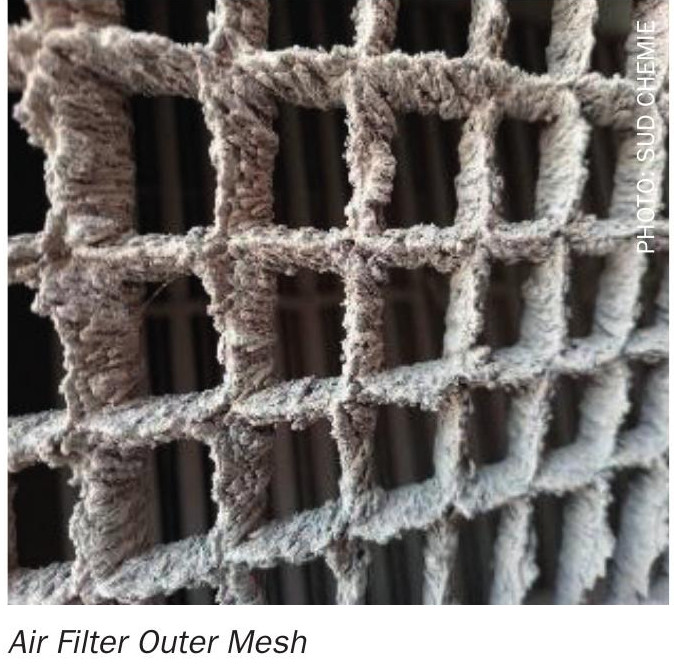

Air: Airborne contaminants are common in fertilizer or bulk-material handling plants. Dust and particulates can deposit on catalyst surfaces, reducing active surface area and affecting DP. Drying tower (DT) position and performance play a significant role in preventing contaminant carryover.

Mitigation measures

Remove contaminants at source using appropriate filtration tailored to the expected inlet contaminants. Common filtration options include pressure leaf filters, cartridge filters, and ceramic cartridge filters; multi-stage filtration is often used. Regular maintenance is essential to keep filtration effective.

For air streams, install proper filtration at blower inlets, ensure the DT operates at its rated efficiency, and consider a mist eliminator at the DT outlet. Some plants use online automated back-flushing systems to remove accumulated dust and improve capture efficiency.

Ensure the proper drying procedure is followed during refractory work in the furnace. Maintain and dry refractory work and other equipment before start-up to avoid carryover. During cold startups, ensure no carbon carryover to the converter during heat-up.

Catalyst safeguards: Catalyst geometry that provides high surface area and higher voidage reduces pressure drop evolution while maintaining conversion efficiency.

Hot gas filters: Hot gas filtration is critical in sulphuric acid plants for removing particulates from high-temperature process gas and protecting downstream equipment. Innovative designs incorporate proprietary technologies to improve efficiency and safety. However, at critical temperatures particulates can become sticky and clog filter candles, increasing DP and may lead to costly shutdowns to clean the filter media. Modern solutions focus on preventing clogging and minimising downtime.

Dust guard catalyst: Installing a dust guard catalyst layer on top of the sulphuric acid catalyst reduces DP evolution. These guard pellets have larger sizes and pore volumes, which preferentially trap dust and impurities while allowing clean gas to pass to the sulphuric acid catalyst.

How SulfoMax GRR (guard catalyst) helps

SulfoMax GRR is a dust-guard catalyst designed to capture and retain contaminants while keeping the gas path unrestricted. Because the gas flow remains

clear, DP buildup is controlled and the rate of DP evolution is reduced.

Chemically similar to functional V2O5 catalysts, SulfoMax GRR features enhanced geometry that improves dust capture and retention. Use of a guard layer reduces screening losses, improves gas distribution, lowers energy consumption, and extends catalyst life. Guard layers also reduce throughput loss and decrease the frequency of screening and related turnarounds.

Primary role: dust protection for the first bed (guard layer) to reduce DP evolution.

Secondary role: in some cases, GRR can replace ceramic inerts as a top support layer.

Other: SulfoMax GRR has a vanadium-based formulation which can initiate the conversion. Advantages over ceramic balls as top layer: greater surface area and a vanadia-containing melt on the catalyst surface that has higher affinity for dust, improving capture efficiency.

Operational note: as dust accumulates and the GRR pores become blocked, the guard layer typically needs replacement every campaign (about 12–18 months). When topping up the guard bed, place fresh GRR at the bottom of the guard layer and discard the exhausted top layer.

Way forward / recommendations

While preventing contaminants at the source is the best way to reduce DP evolution, an additional safeguard is to protect the converter’s first bed with a guard catalyst layer. A modest addition of guard catalyst provides a fail-safe even when feed purification is well controlled, prolonging converter campaign life. Benefits of a guard catalyst layer include:

- lower DP evolution, maintaining plant throughput;

- no additional power consumption;

- safeguards main catalyst activity by arresting carryover;

- unaffected catalyst conversion;

- longer catalyst life;

- longer campaign life, reducing screening frequency and related turnaround costs and stoppages;

- effective replacement for inert hold-down layers where headroom is limited;

- can be used after intermediate absorption stages to protect against mist carryover.