Sulphur 422 Jan-Feb 2026

28 January 2026

Defined, designed, delivered, diagnosed

MIST ELIMINATOR TROUBLESHOOTING

Defined, designed, delivered, diagnosed

Mist eliminators in sulphuric acid plants are critical for maintaining production, protecting downstream equipment and minimising emissions, with each type having specific velocity ranges and turndown limits that determine particle size capture performance. Graeme Cousland of Begg Cousland Envirotec reviews different mist eliminator types and some of the operational problems encountered which can be managed by correct installation, targeted cleaning or replacement, and selecting appropriate corrosion-resistant materials.

The duties of mist eliminators in a sulphuric acid plant are significantly important for maintaining production, for protecting downstream equipment and for minimising the environmental impact of its atmospheric emissions. Therefore, the design of the correct type of mist eliminator to meet the efficiency and pressure loss requirements is critical. Equally critical, however, is the understanding of the problems and challenges mist eliminators face during their operational lifetime, and the role played by troubleshooting.

Broadly speaking, sulphuric acid plant mist eliminators come under the following two groupings:

- Demister droplet separators:

- Knitted wire mesh demisters

- Co-knitted wire and fibre yarn mesh coalescer/demisters

- Structured mesh demisters

- Mist eliminator fibre beds:

- High velocity, impaction type

- High efficiency, low velocity Brownian diffusion type

The main issues that arise during operation and can affect all above mist eliminators are:

- Blockage by solids, insoluble or undissolved

- Process excursions (e.g. higher temperature, higher acid load) affecting efficiency

- Chemical attack (e.g. HF)

- Corrosion due to diluted acid (e.g. water leaks, humidity ingress)

Demister droplet separators

Knitted wire demisters, which catch droplets larger than 5 microns, and coalescer/ demisters or structured mesh pads, which catch particles of 2 microns and larger, are traditionally installed horizontally, or conically, in drying towers (some older plants may still have absorbing towers equipped with them still). The typical velocity range is between 2.0 and 3.5 m/s and they have a turndown to 30% before any loss of efficiency would take place.

Designed and sized to give guaranteed pressure loss and efficiency, problems happen when solids begin to block the mesh. The more dense and therefore the more efficient the mesh pad, the faster the blockage increases the pressure loss and causes flooding. The velocity through the remaining free volume of the mesh pad will entrain droplets from the flooded mesh pad. The solids can be ferrous sulphate (full surface or partial surface blockage), atmospheric dust or insoluble particles not removed by an upstream gas cleaning section, sublimed sulphur or nitrosyl crystals.

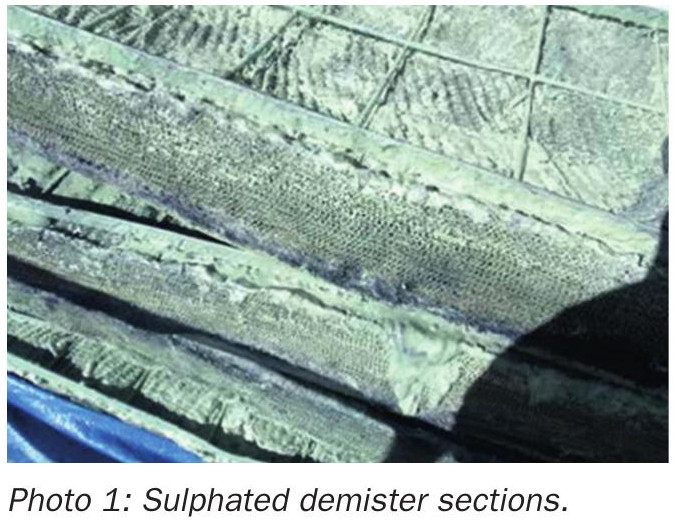

When inspecting the mesh pad in the tower from above you may be able to see evidence of sulphates (see Photo 1). However, it should already be expected if the recorded pressure loss trend showed a gradual or rapid rise of 30% or more. The demister would need to be cleaned or replaced.

Replacing the mesh pad with a less dense mesh style may slow the rate of blockage but the resultant reduction in efficiency is the trade-off. Installing a structured mesh style, however, is one way that pressure loss can be reduced while maintaining the overall collection efficiency (see Photo 2). Structured mesh pads are also generally easier to wash and re-use.

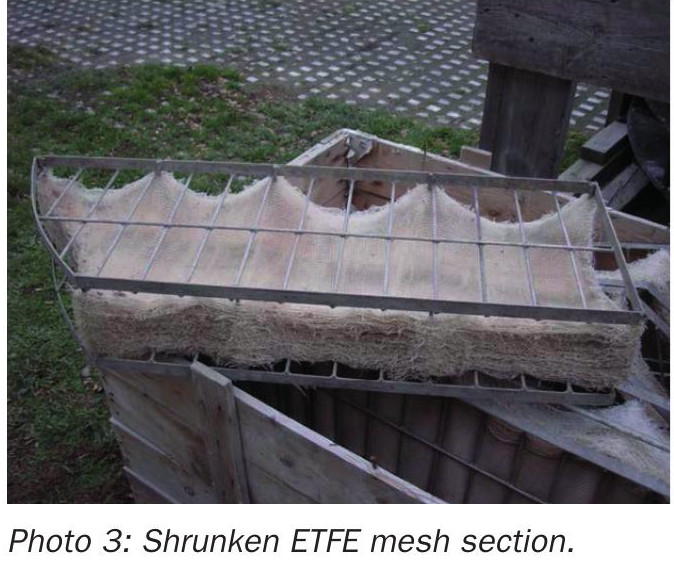

Corrosion of metal wire mesh (or even support grids) can be identified during an inspection and may be anticipated if acid drainage downstream increases. Corrosion may sometimes be localised, rather than general, and may point to a problem lower down in the tower. Depending on operating conditions, required campaign length etc. the choice usually lies between 316L stainless steel, Alloy 20, high silicon alloys (e.g. Saramet 35 or SX) or ETFE fluoropolymer. The latter does not corrode but is heat sensitive and eventually shrinks above 80˚C and does not usually last longer than three to four years (see Photo 3). Alternative arrangements, such as ‘brickwork’ ETFE mesh pad sections can help.

Ensuring that the mesh pads are correctly installed may sound obvious but sadly is often overlooked. If the mesh pad sections are not fitted and compressed in sequence as directed by the supplier’s instructions, then you may not get the final section(s) in place. Worst case, unbelievably, is to find that the external contractor decides unilaterally to cut the mesh, thereby destroying the intentional oversize compression fit – resulting in gaps between adjacent sections and no mesh circumferential seal around the shell and therefore gas by-pass. Distances between the support grids on adjacent demister sections should be equal. Order a roll of extra, spare mesh which can be used to create a circumference seal against the shell where it is not truly round.

Additionally, ensuring correct installation also means that the demister is securely held in position against the upward gas flow. The fixing method should be strong enough to hold every section in place even when the mesh pad is being blocked. Only using tie wire is often insufficiently strong. Angle section hold-down bars on top or hook-bolt and clamp sets from below are recommended.

Troubleshooting such matters above is always good when a physical inspection can be made. During operation there are other tasks that need to be carried out regularly to monitor the demister’s performance:

• Keep a record of the pressure loss to observe trends, up or down, and the rate of change.

• Do regular stick tests to check on changes of efficiency – sizes and quantities of acid burn marks on the stick, which can be photographed and kept for later comparison.

• Carry out sight glass observations, if possible.

• Record downstream acid drainage rates and changes.

Mist eliminator fibre beds

There are four ‘collection mechanisms’ applicable to mist elimination: impaction, interception, coalescence and Brownian diffusion. The impaction type of mist eliminator works purely mechanically, passing the acid particle-laden gas through, variously, coarse glass fibres and/or knitted wire mesh layers, often comprising multi-media materials. These materials are lighter density fibre beds, relying on the momentum of the acid particles to hit a fibre or wire and be collected, draining away from the gas flow. Used in drying towers and in final absorbing towers, they are generally between 1.0 and 1.6 m long, standing on a supporting tubesheet, so that the gas passes from inside to outside and the collected acid drains down the outer surface. Efficiencies vary according to the composition of the filtration media, but their efficiency reduces below 3 microns and they have little effect below 1 micron.

The typical velocity range is between 1.5 and 2.5 m/s and they have a turndown only to 50% before any loss of efficiency would take place. That means they must be carefully designed for duties with varying gas flow conditions, since at slower gas speeds through the filtration media acid particles can slip-stream past the fibres and wires. As an analogy, imagine riding a motorcycle through a forest – at high speed you would not be able to avoid hitting a tree, but at slower speeds you can weave your way between them. There is also a risk in a final absorbing tower of a visible stack plume if the regime in the tower changes due to a process upset or upstream equipment problem, generating more mist below 3 microns.

The Brownian diffusion type of mist eliminator uses all four mechanisms, but it is Brownian diffusion that gives the ability to collect sub-micron acid aerosols as well as larger particles and droplets. For optimum Brownian diffusion the gas would pass through the dense, saturated bed of small diameter glass fibres at a speed in the range of 0.05 to 0.25 m/s. Within that velocity range the sub-micron aerosols move randomly due to the random motion of the gas molecules and then contact a fibre where they are collected drop-wise or film-wise, before draining down the exit surface of the mist eliminator. The analogy here involves you walking carefully between trees in a dense wood, but gusts of wind push you onto trees. The slow gas velocities required mean that long mist eliminators can be used, hanging or standing, and many of them to keep the pressure loss within a reasonable range.

Typically, the emissions from absorbing tower Brownian diffusion mist eliminators will be below 30 mg/Nm3 and mostly less than 20 mg/Nm3 which means the stack will be optically clear. As the performance of Brownian diffusion mist eliminators can be guaranteed even with a turn-down to 30% it makes them invaluable for both intermediate and final absorbing towers.

When inspecting standing type mist eliminators in the tower, the inlet surface is the inside, which is visible from below. It is important to check the inside for signs of solids blockage (see photos 4 and 5) and, visible from above, for signs of sulphate deposits/formation.

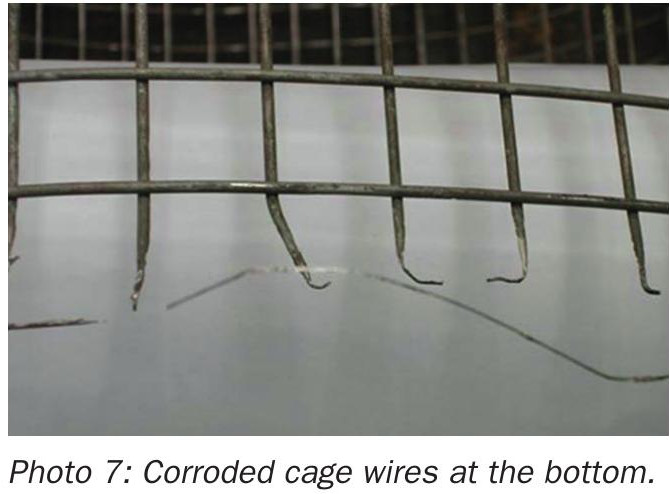

Corrosion of mist eliminator structures is initially found at the bottom of the structure, where a small amount of acid remains undrained from the fibre and which gets diluted by humidity, for example. The cage wires being the thinnest material involved are then corroded and, if they are welded to a flange or plate, the structure’s integrity will begin to fail (see photo 7).

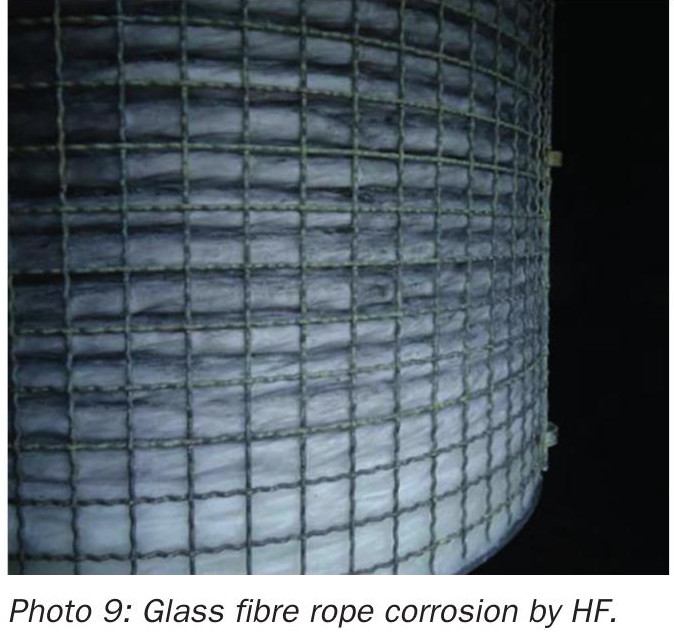

When there is fluorine present in the gas, this will form HF which corrodes glass fibre, randomly and initially visible near the top of a mist eliminator (see photos 8 and 9). As the glass fibre bed thins and develops holes, there can be a noticeable decrease in pressure loss and a loss of efficiency seen on stick tests.

Good practice, when opening a tower during a shutdown, is to take general photos from the manway before any workers enter the tower. That way you can potentially see evidence of flange leakages (e.g. wet areas vs dry areas, traces of flange gas by-pass on tubesheet) before a team’s boots disturb everything and cleaning begins. Simple, avoidable things happen like incorrectly torqued or missing bolts which mean that the flange/gasket seal is compromised and gas by-pass takes place. central area of tubesheet and flange sealing. With hanging type mist eliminators, however, they can usually be inspected in the tower from below (looking for signs of solids on the fibre) and from above. In the case of fibre bed blockage by nitrosyl

Maintenance of demisters and mist eliminators

Cleaning a knitted mesh pad is not always easy. Using a hot water lance spray can be effective, but when there are solids in the middle layers of the mesh pad, it is a challenge. Even when there are only sulphates on the middle of the demister (fallen down from the carbon steel exit duct), failure to wash these away can lead to weak acid formation and wire mesh corrosion.

Care should be taken when the demister sections are removed from and re-installed into the tower. As previously mentioned in the comments on a demister’s compression fit, the workers should expect a degree of resistance when removing the central sections. Damage done at this point can compromise the demister when the sections are re-installed. Bending of support grids and crushing of the mesh pad’s sides can be hard to repair but would lead to gas by-pass if left untouched (see photo 10).

It is also the case that repeated handling of mist eliminators involves risk of damage. However careful a crane operator tries to be, a 3.66 m long mist eliminator swinging out from, or back into, a tower manway or tubesheet hole can be damaged by hitting the circumference of the hole through which it is being lifted.

When cleaning the fibre beds of mist eliminators, care should be taken not to damage them by too high hose water pressure, or rapid lifting out of wash tanks causing excessive hydraulic stress on the fibre or by careless handling. After the final washing step (see Washing Guide on www.beggcousland.com) both demisters and mist eliminators should be dried as much as possible to avoid weak acid formation when back in operation. When deciding whether to wash or replace mist eliminators, it is unusual for an impaction type to be usable after a second washing. Brownian diffusion type can require washing due to general solids or sulphur sublimation, but in the case of the former reason it should be justified by a significant increase in pressure loss and not as a routine activity. It is not 100% effective in reducing the pressure loss to the original, clean state. Using an experienced, specialist company to do the washing is advisable, if available.

Taking care of your operating, maintenance and other procedures is a key target when getting the most life from your mist elimination equipment. Begg Cousland Envirotec understands how to customise mist eliminators for optimum performance, how to produce them reliably and how to assist customers with the troubleshooting assistance needed. Defined, designed, delivered and diagnosed.