Fertilizer International 530 Jan-Feb 2026

23 January 2026

The shift in food and agriculture

VILLETA PROJECT UPDATE

The shift in food and agriculture

The ATOME-CASALE Villeta Project in Paraguay represents a significant step forward for fertilizer sustainability. As the fertilizer industry moves toward decarbonisation, the project is emerging as a leading reference for future low-carbon fertilizer production. CASALE’s Giovanna Roviello, Process Manager, and Francesco Baratto, Head of Syngas Department, provide an update on the progress of Villeta as it approaches a final investment decision.

Introduction

The global fertilizer industry is undergoing a profound transformation as producers seek out low-carbon feedstocks and sustainable production routes. Within this context, the ATOME-CASALE Villeta Project in Paraguay stands out as one of the sector’s most promising and advanced green fertilizers developments.

Supported by abundant baseload hydropower and state-of-the-art process design, the project aims to deliver competitive, low-carbon fertilizer for both domestic and international markets. This article presents an overview of the project – with a particular focus on engineering progress and the EPC (engineering, procurement and construction) development strategy.

A fully-integrated production centre

The Villeta project has been conceived and engineered as a fully integrated production complex, covering the complete value chain from the sourcing of the renewable electricity to the manufacture of calcium ammonium nitrate (CAN) at the scale of 260,000 tonnes per annum (t/a). The project’s design philosophy focuses on high energy efficiency, operational reliability, and minimal environmental impact. All core process technologies are sourced from the CASALE portfolio, ensuring a high level of integration, consistent design standards, and optimised performance across the entire plant.

At the front end of the production complex, renewable electricity and water are converted into green hydrogen. This is combined subsequently with a high purity nitrogen feedstock and processed into ammonia and downstream products such as nitric acid and CAN.

The main process units of the complex include:

• A water electrolysis plant. This produces green hydrogen using renewable power.

• An air separation unit (ASU) supplying high-purity nitrogen.

• An ammonia synthesis loop. This operates with CASALE’s proprietary SMART-N technology with a configuration designed for high efficiency and flexible operation under variable power supply.

• A nitric acid plant. This is based on CASALE’s dual-pressure DualPURE process and provides high conversion efficiency and low emissions.

• An ammonium nitrate solution (ANS) production unit. This utilises CASALE’s NitroPIPE technology, with enhanced safety and heat management.

• A granulation plant for CAN production. This is based on CASALE’s NitroCULTIVA drum granulation technology to deliver consistent product quality and robust granule strength.

The complex – beyond the core process units – is also equipped with comprehensive utilities and offsite systems. These include water treatment, cooling facilities, power distribution, and storage infrastructure, as well as administrative, maintenance, and logistics buildings to support long-term operation.

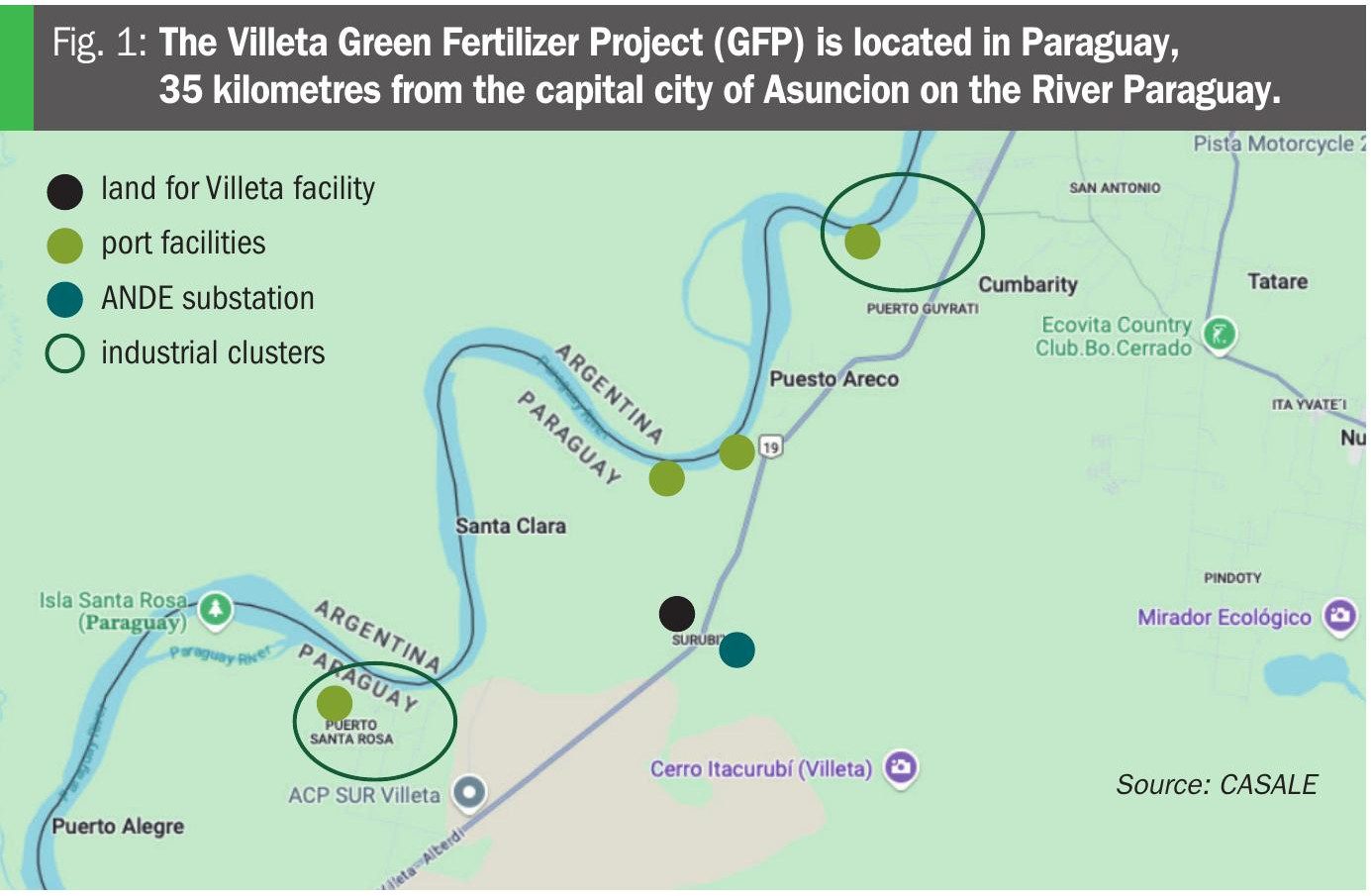

Villeta, the selected location for the production complex (Figure 1), offers access to reliable, cost-effective renewable electricity, due to its close proximity to Paraguay’s hydropower grid. This advantage is a critical enabler for the economic viability and competitiveness of both green ammonia production and – ultimately – the downstream manufacture of fertilizer at the site.

The shift in food and agriculture

Nitrogen fertilizers are the backbone of modern agriculture, being responsible for feeding up to 50% of the world’s population. Yet agri-food systems also contribute 30% towards global greenhouse gas (GHG) emissions. Hence the fertilizer industry, which has largely been driven by production volumes previously, is now shifting its focus towards agronomic efficiency and more sustainable ways of making affordable crop nutrients at scale.

When it comes to sustainability, the production of low-carbon nitrogen fertilizers – from ammonia via the green hydrogen route – offers a particularly impactful and scalable near-term solution. The ease with which this manufacturing process can be readily integrated within today’s food and farming value chains, versus other options, also makes it a highly promising production route. Indeed, the evidence from recent reports (Hydrogen Council, McKinsey & Company) is that using low-carbon fertilizer can reduce up to 30% of food product emissions while adding only an extra 1-3% to food product end-costs.

Major food and consumer packaged goods (CPG) companies are also now taking decisive steps and setting ambitious Scope 3 emissions targets – aided by the market push from the regulatory environment and global standards (e.g., CBAM, REDIII, SBTi) – a move which is supporting the adoption of low-carbon fertilizers across their value chains.

The low-carbon fertilizer supply agreements already announced between Yara international (the marketing partner for Villeta) and both PepsiCo and chocolate manufacturer Barry Callebaut are notable examples. Major players such as Nestlé, Unilever, Mars and M&S are among other major brands committed to sustainable farming practices to tackle Scope 3 emissions.

The Villeta project represent an accelerator of this sustainability shift in food and agriculture, with a production process that could potentially displace up to 12.5 million tonnes carbon dioxide equivalent (CO2e) over its life. Moreover, at a time when demand for sustainable fertilizer products is intensifying, the CAN market itself is growing due to the product’s superior agronomic performance. Compared with widely-used urea-based fertilizers, CAN has a higher nutrient use efficiency (NUE) – making it better positioned for the farming needs of the future.

Project Status

The Villeta project has successfully completed conceptual engineering and FEED (front-end engineering design) phases. Key permits are obtained, initial site preparation activities are underway, and the necessary vendor engagement for long-lead equipment items has been completed. Discussions with financing institutions, meanwhile, are near to completion – with early 2026 being the current target for a final investment decision (FID).

Engineering

Engineering work for this green fertilizer project is at an advanced stage and continues to progress ahead of the contractual schedule in several critical areas. Following completion of the FEED, a series of detailed engineering tasks have been initiated and completed ahead of the FID.

A thorough review of the Contractual Project Schedule has been carried out. This identified priority engineering activities with particular emphasis on the first 12 months of execution and critical-path activities. The gains from this review have meant progress to date has been ahead of schedule, reinforcing overall confidence in the ability to meet the contractual project duration.

Key engineering deliverables have been completed or are well advanced, including process unit documentation, equipment datasheets, and P&IDs (piping and instrumentation diagrams). Reviews of the 3D model and HAZOP (hazard and operability) studies for technological units are ongoing, enabling early incorporation of client feedback and mitigation of potential downstream impacts.

Procurement

Procurement activities are advancing in parallel with engineering, with a particular focus on long-lead and schedule-critical equipment packages.

Technical specifications, bid evaluations and tabulations have been prepared for major equipment, including electrolysers, electrical systems (switchyard, transformers and switchgear), the air separation unit, main compressors, converters and heat recovery equipment.

For several critical packages, commercial and technical negotiations with suppliers are already underway, while others have entered, or are ready to enter, the purchase order placement phase. Early and structured engagement with vendors is enabling confirmation of delivery schedules and manufacturing capacities, thereby reducing exposure to supply-chain constraints and mitigating the risk of cost escalation.

Construction

Construction preparatory activities are progressing in parallel with engineering and procurement. The site preparation engineering package has been completed, for example, and ATOME is working with subcontractors to handover the site area to CASALE ahead of the original schedule. In addition, early arrangements have been defined to accelerate the availability of power supply and river water at the plant battery limits, supporting early mobilisation and overall construction readiness.

In parallel, subcontractor scouting and prequalification are underway, together with permitting and logistics planning, to ensure that construction activities can commence promptly once the project becomes executable.

Project execution programme from FID

Following the FID, the project execution strategy will have a total duration of around 40 months – from commencement to handover – with plant start-up scheduled for the first quarter of 2029. This execution timeline is achievable, despite the scale and complexity of the project, thanks to CASALE’s extensive track record in delivering lump-sum turnkey EPC fertilizer projects.

Fundamental to the execution strategy is CASALE’s integrated delivery model. This places the licensor and EPC contractor together as part of the same project organisation throughout the project’s full lifecycle, from technology licensing through to the point when the complex is in a ready-for-start-up condition. This integration eliminates transition risks between different project phases, avoids bottlenecks relating to licensing approval, and ensures early involvement of the construction and commissioning teams.

Construction and commissioning considerations are embedded within the project as key drivers from the earliest engineering stages. The engineering organisation operates in close coordination with construction and commissioning specialists, enabling early identification and mitigation of execution risks.

Throughout all project phases, rigorous project control processes are applied to ensure schedule adherence, cost discipline and quality compliance. These include:

• An integrated planning and progress measurement system covering the full project duration.

• Structured cost control with forecast trending of costs and worker-hours.

• The application of CASALE’s Quality Management System across both supplier and subcontractor scopes.

CASALE’s quality system is fully compliant with the UNI EN ISO 9001:2015 standard, ensuring consistent and effective control of project activities.

Conclusions

The ATOME-CASALE Villeta Project represents a significant step forward for sustainable fertilizer production in Latin America and the wider global industry. Supported by a strong business case and market conditions, available renewable resources and a solid lumpsum turnkey EPC execution plan, the project demonstrates how green fertilizers can be produced competitively and at scale.

As the industry moves toward decarbonisation, the Villeta project – as a leading reference for future low-carbon fertilizer production – offers a replicable model that combines technical reliability, environmental integrity and commercial viability.