Nitrogen+Syngas 398 Nov-Dec 2025

24 November 2025

Technology pathways to clean ammonia

LOW CARBON AMMONIA

Technology pathways to clean ammonia

Ammonia is poised to grow beyond fertilizers into energy transition roles, with low-carbon pathways via blue ammonia and green ammonia, supported by existing logistics and market structures. To support this transition, Stamicarbon is expanding its NX STAMI™ ammonia technologies – with a medium-pressure design for large, CCUS-integrated plants and a high-pressure design for small/ medium renewable projects – demonstrating efficiency, reliability, and cost advantages.

While global demand for nitrogen-based fertilizers is sustained, the ammonia production and distribution landscape is undergoing a significant transformation. This change is driven by evolving global supply chains and the ambition to reduce greenhouse gas (GHG) emissions, supported by government regulations and incentives.

Beyond its role as a feedstock for fertilizer production, ammonia is gaining recognition as a key enabler of the energy transition. Clean ammonia – produced from low-carbon hydrogen – can serve as a hydrogen carrier or fuel, helping to decarbonise hard-to-abate sectors. It is relatively easy to store and transport in bulk, with well-established distribution networks and trading markets. This makes ammonia a practical solution to transport renewable energy from where it is generated to where it is needed.

As a result, ammonia production is expected to continue growing, either in line with global population and economic development or at an even faster pace as it enters new industries. To support this transition, Stamicarbon, the nitrogen technology licensor of NEXTCHEM, is expanding its ammonia technology portfolio to deliver highly reliable and cost-effective solutions for different plant scales and feedstock types (Fig. 1).

Paths to low-carbon ammonia

Reducing the carbon footprint of conventional ammonia production can be achieved by integrating carbon capture, utilisation, and storage (CCUS) systems. This way, over 95% of the CO2 that would normally be emitted can instead be captured for storage or use in other processes.

Alternatively, ammonia can be produced with near-zero carbon emissions using hydrogen generated by water electrolysis powered by renewable sources such as wind, solar, hydro, or geothermal electricity.

Both approaches are essential for the sustainable transformation of the ammonia industry. Blue ammonia leverages established large-scale processes with added carbon capture to deliver immediate CO2 reductions, while green ammonia offers fully renewable production pathways.

Stamicarbon’s ammonia technology portfolio includes two designs tailored to different project sizes, feedstocks, and sustainability goals. These technologies can be applied to large-scale production from fossil sources with CCUS integration, or to small- and medium-scale production from renewable electricity.

Economy of scale

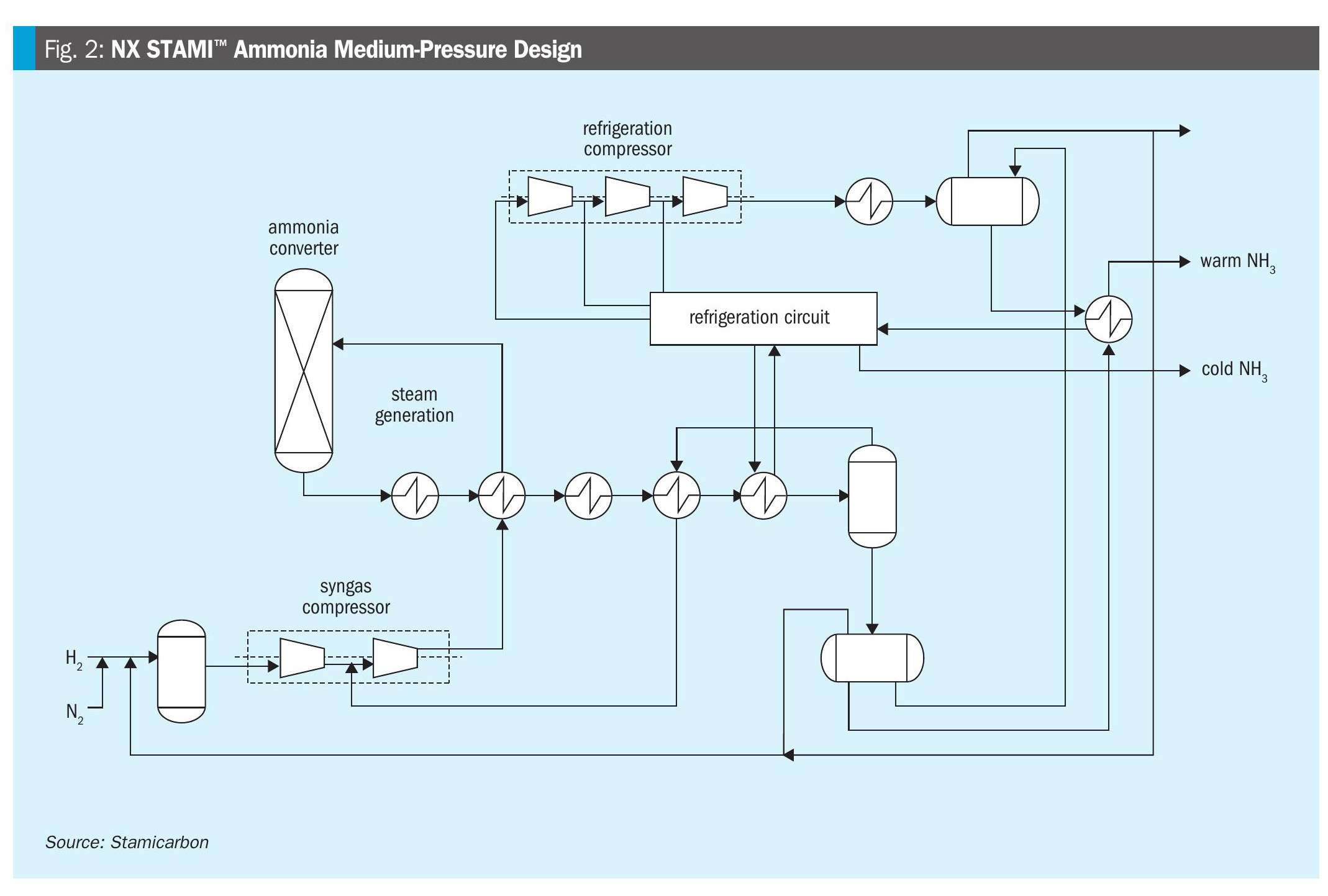

To meet the demand for cost-effective and energy-efficient ammonia production, Stamicarbon offers the NX STAMI™ Ammonia Medium-Pressure Design. This optimised Haber-Bosch process is suited for capacities from 50 to 3,500 t/d. A conventional large-scale plant using this design can produce low-carbon ammonia by integrating carbon capture at the front end. With more than 45 industrial references worldwide, this design is a proven, reliable, and economical solution for achieving efficiency at scale.

In Stamicarbon’s medium-pressure design (Fig. 2), ammonia synthesis is carried out in a reactor configuration that minimises pressure drop. This design maximises the per-pass conversion of hydrogen and nitrogen with effective catalyst utilisation. The converter’s first catalyst bed has superior temperature control, enabling more efficient operation and extending catalyst life by avoiding hot spots. The result is a highly efficient loop that ensures more ammonia yield while consuming less energy. By fine-tuning operating parameters, such as pressure, flow rates, and recycle ratios, the process can be adapted to specific project needs and conditions.

For blue ammonia projects, Stamicarbon provides advanced autothermal reforming (ATR) technology through its parent company, NEXTCHEM. ATR produces a high-pressure syngas stream with a high CO2 concentration, making downstream carbon capture significantly more efficient. This approach can achieve CO2 capture rates above 98% with 40% less solvent circulation (compared to conventional amine-based solvent technologies).

NEXTCHEM’s ATR operates at high pressure (above 60 barg), reducing the compression duty in the synthesis loop. This leads to lower capital and operating costs. The process uses robust, well-proven equipment and a simplified scheme that improves overall energy efficiency.

When combined with CCUS, an ATR-based ammonia plant can deliver world-scale output with a considerably smaller carbon footprint, offering “big blue” ammonia with strong economic performance.

Designed for renewables

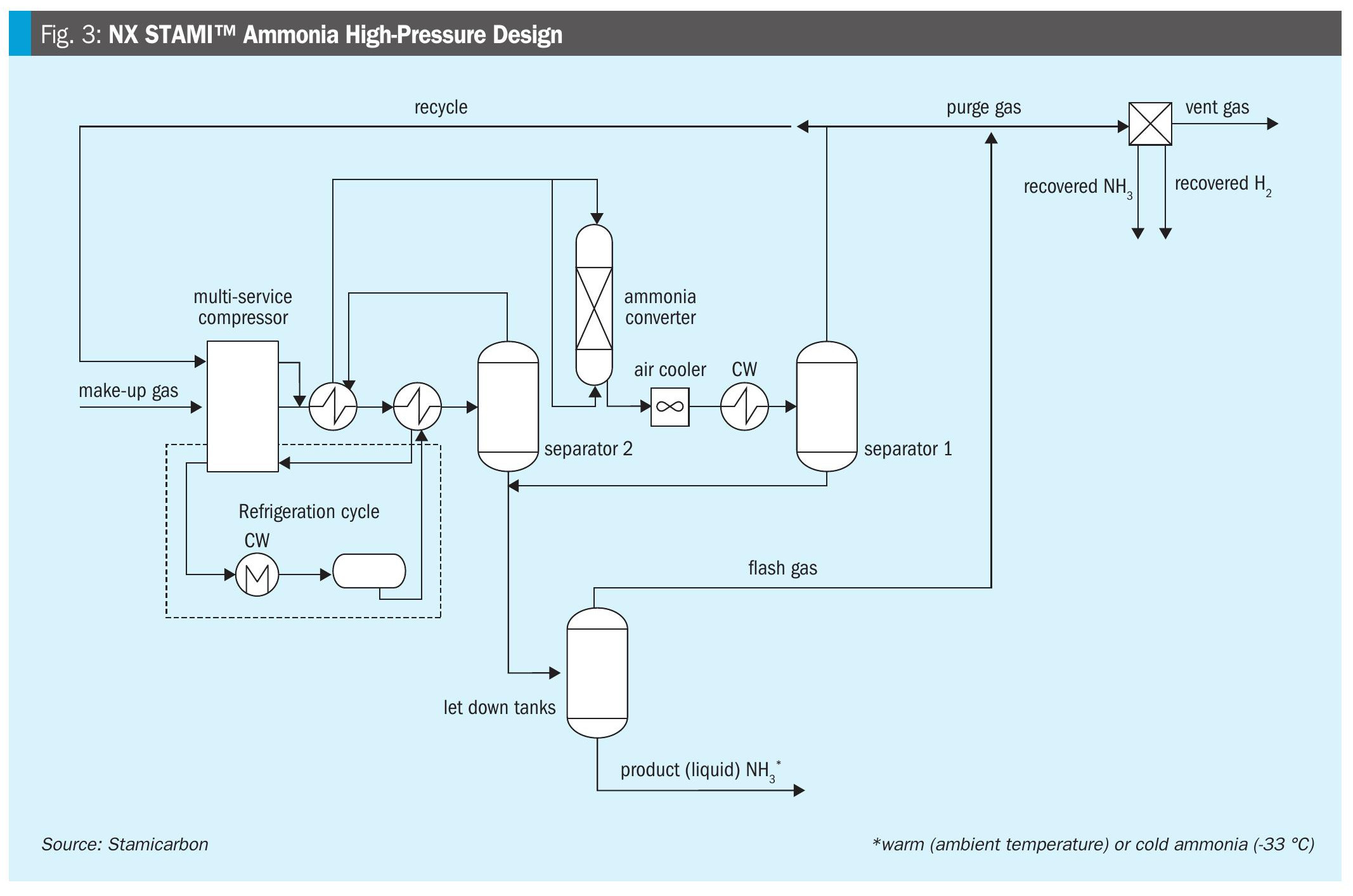

The NX STAMI™ Ammonia High-Pressure Design (Fig. 3) opens up new possibilities for producing ammonia from renewable electricity. Engineered for capacities between 50 and 500 t/d, this process maximises efficiency and simplicity. Its high-pressure synthesis loop (operating above 300 bar) achieves high per-pass conversion, reducing the need for recycle compression and refrigeration – an important advantage for smaller plants where simplicity and efficiency are critical. This setup can lower capital expenditures for the synthesis section by approximately 25–30%.

The high-pressure design uses a single-bed axial-flow ammonia converter with a compact tubular reactor design. Inside the converter, heat exchanger tubes are submerged within the catalyst bed to carefully control the temperature profile. Precise temperature control prevents hot-spot formation and catalyst sintering, prolonging catalyst life and maintaining performance. An integrated start-up heater is also included within the converter, allowing the reactor to heat up smoothly during plant start-up. Thanks to the high operating pressure, the converter and other equipment can be made more compact, and the overall footprint of the plant remains very small – a key benefit for decentralised or modular green ammonia installations.

The entire synthesis loop, including both fresh make-up and recycle gas, is handled by a single, electrically powered reciprocating compressor. This reduces the number of compressors required, enhances reliability, and minimises maintenance costs. The NX STAMI™ Ammonia High-Pressure Design is well-suited for distributed, small-scale green ammonia projects that can later be scaled up as renewable capacity expands.

With four operating references, Stamicarbon holds the strongest track record in the sub-500 t/d segment. By leveraging this proven technology, early adopters in the green ammonia market can achieve their decarbonisation goals and prepare for future expansion as renewable electricity becomes cheaper and electrolyser capacity grows.

Reducing the footprint of nitrogen fertilizers

In an integrated low-carbon fertilizer complex, shared process streams, such as oxygen from water electrolysis, can significantly enhance efficiency. These synergies save energy, lower emissions, and reduce both capital and operating costs through shared utilities and infrastructure.

A notable example of such integration is the FertigHy project in France, which is expected to start construction in 2027. The plant will produce 500,000 tonnes of low-carbon nitrogen fertilizers per year using hydrogen from renewable and low-carbon electricity. NX STAMI™ Ammonia and NX STAMI™ Nitrates technologies will enable ammonia and nitric acid production with minimal greenhouse gas emissions.

Stamicarbon is also engaged in renewable ammonia projects in Angola, Kenya, Indonesia, Qatar, and the United States, further supporting the global shift toward cleaner fertilizer production.

Conclusion

The availability of advanced ammonia technologies tailored to different feedstocks, scales, and applications is enabling a new generation of economically viable, low-carbon ammonia plants. By combining clean ammonia production with downstream processes such as urea and nitrates, fully integrated fertilizer complexes can be designed to meet both environmental and commercial goals. These facilities make low-carbon production across the agriculture and energy vectors achievable and viable.