Sulphur 421 Nov-Dec 2025

24 November 2025

Platinum-catalysed conversion of sulphur species

OXIDATION CATALYST

Platinum-catalysed conversion of sulphur species

Platinum-promoted honeycomb catalyst bricks offer lower pressure drop, higher activity, reduced toxicity, and function as total oxidation catalysts that convert all oxidisable species under appropriate temperature and oxygen conditions. A case is presented for a sulphur-resistant total oxidation catalyst processing a gas stream bearing high amounts of H2S – relevant to the fibre industry, Claus offgas treatment, and other chemical sectors. Proper parameter settings enable conversion of H2S to SO3 for concentrated sulphuric acid production. Additional applications for the total oxidation catalyst include metallurgical offgas treatment, VOC abatement, and CO abatement under harsh conditions.

Johannes Hofer, Alexander Sigg, Michael Felsberger and Paul Piantino (P&P Industries AG)

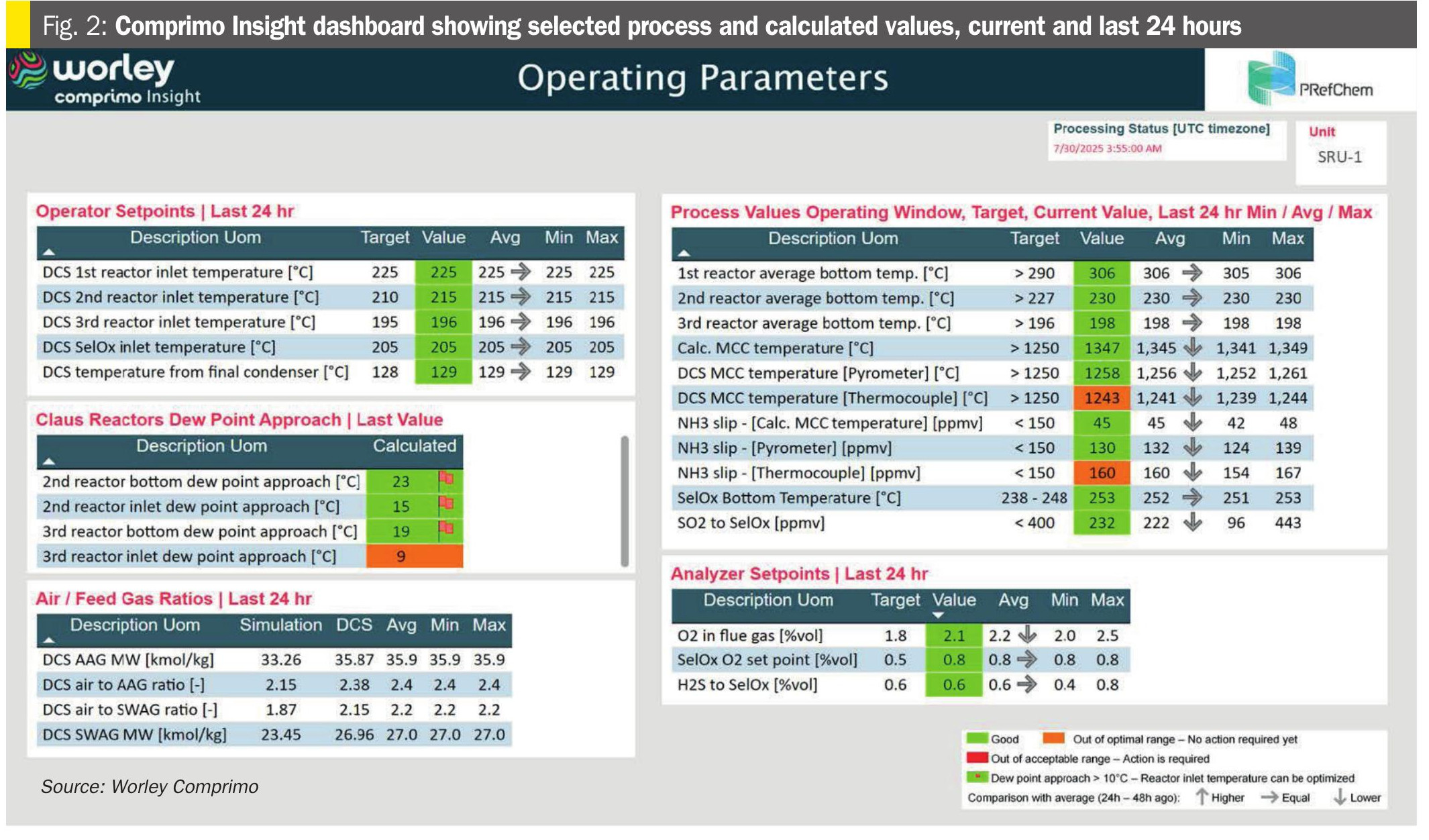

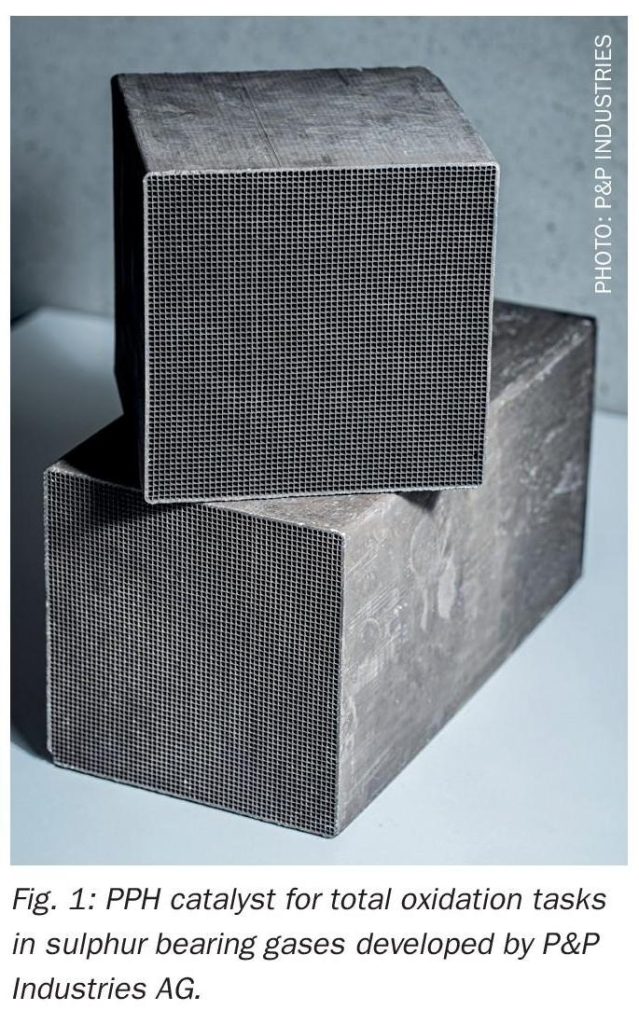

Platinum-promoted honeycomb (PPH) catalysts developed by P&P Industries AG (see Fig. 1) represent a significant technological progress compared to conventional bulk catalysts traditionally used in industrial oxidation processes of sulphurous species such as H2S or SO2 . Their structured monolithic geometry enables low pressure drop – even at high gas flow rates. At the same time, the highly dispersed platinum active phase provides superior catalytic activity and thermal stability. Unlike almost all state-of-the-art oxidation catalysts applied in sulphuric acid manufacturing, which are typically based on vanadium pentoxide (V2O5 ), the VividOx PPH catalyst provided by P&P Industries shows lower toxicity and extended operational lifetime. The combination of these factors, together with its high catalyst poison resistance, underlines its high suitability for the typically challenging industrial environment.

A distinguishing characteristic of the PPH catalysts is their total oxidation capability. Under appropriate operating conditions – specifically, sufficient temperature and controlled oxygen availability – these catalysts are capable of oxidising virtually all oxidisable components in a process gas stream, making them a highly versatile tool in multipollutant environments.

The presented study focuses on the turnover behaviour specifically for the oxidation of hydrogen sulphide (H2S), a species that poses health, safety and environmental hazards while being present in the tail gas of numerous industrial processes. High H2S loadings are a typical challenge in fibre production facilities, Claus tail gas treatment units, and a range of chemical process industries. Due to its toxicity and corrosive nature, H2S must be converted efficiently and reliably removed from the respective gas stream before being released or further processed.

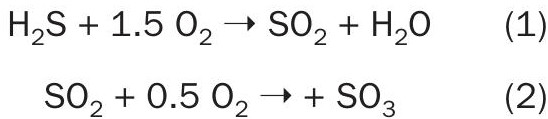

The catalytic oxidation using total oxidation catalysts like P&Ps VividOx PPH catalyst presents a robust solution to this challenge. The primary oxidation of H2S to sulphur dioxide (SO2 ) proceeds via a strongly exothermic reaction pathway, with high conversion achievable due to the reaction equilibrium, which is strongly in favour of the products (see equation 1). Modulating oxygen concentration, temperature and residence time accordingly, SO2 can subsequently be oxidised further to yield sulphur trioxide (SO3 ) as indicated in equation 2. The integration of such a catalyst into an acid production loop offers opportunities to transform H2S-rich off-gas into valuable downstream products, resulting in both environmental and economic advantages.

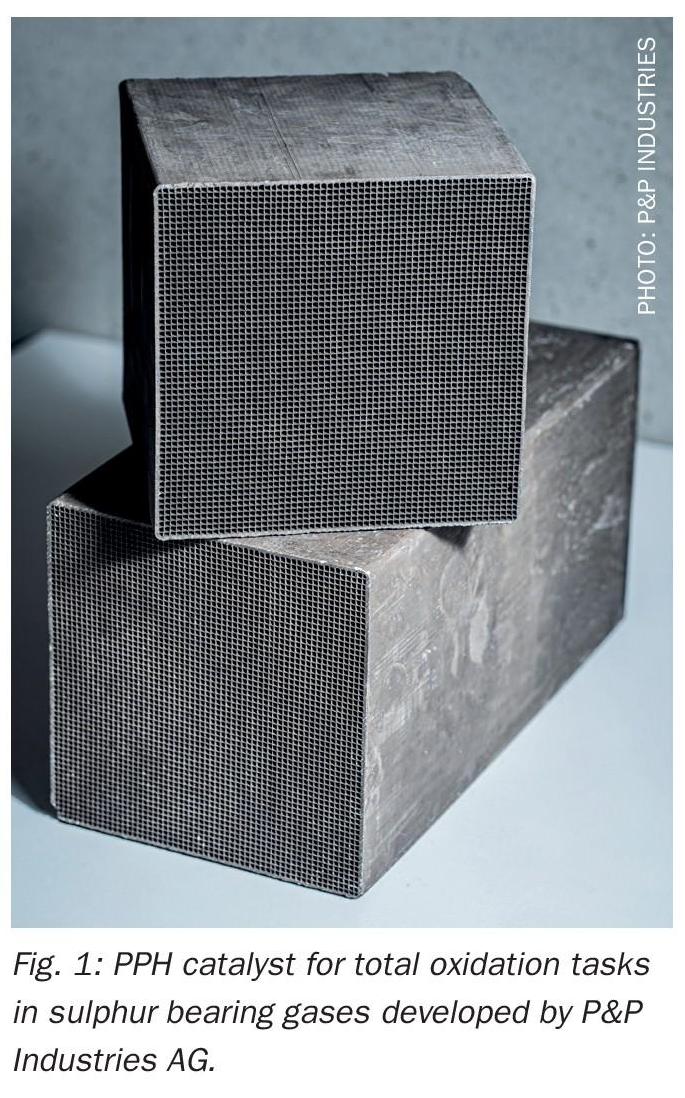

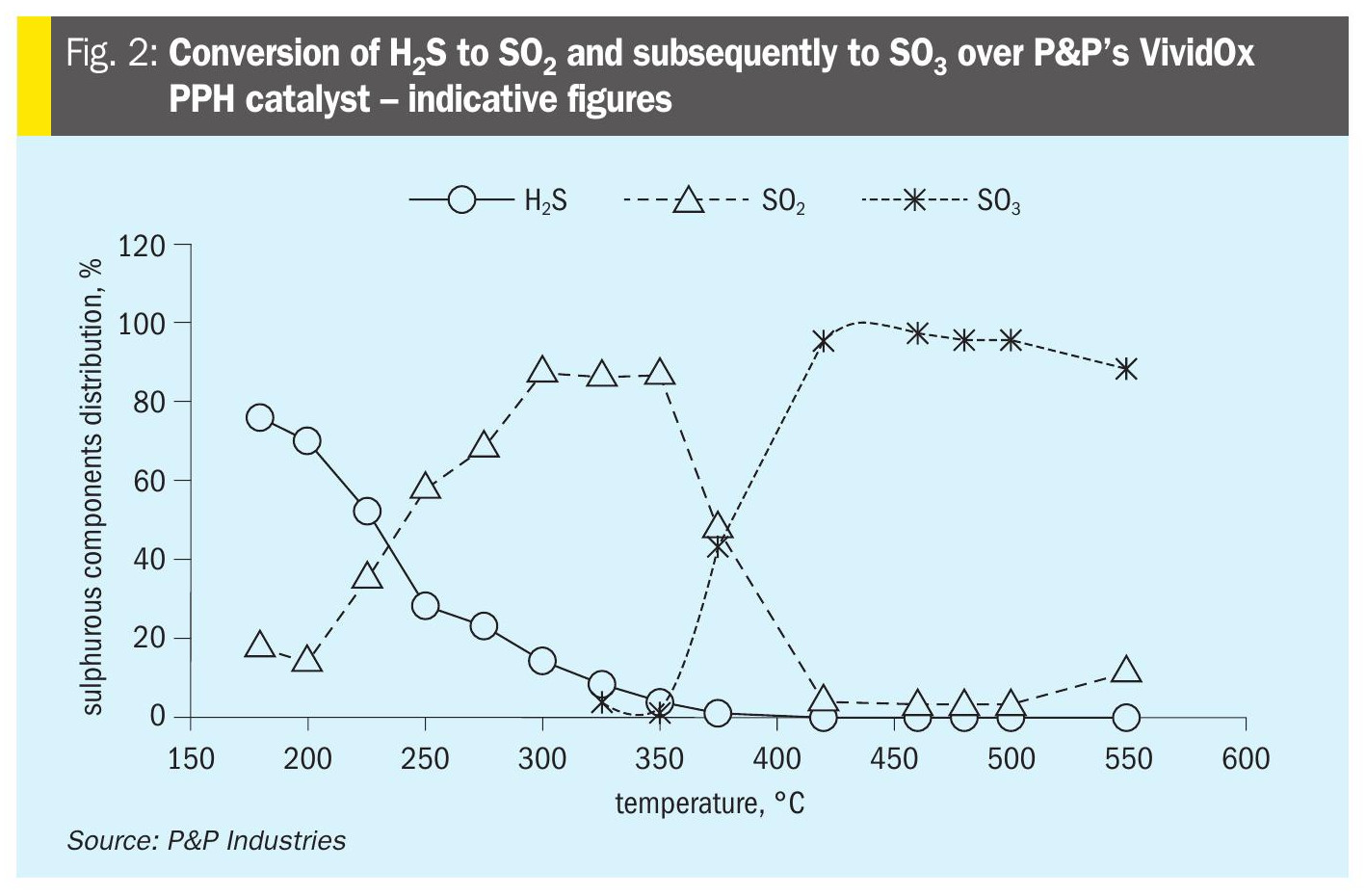

The experimental study performed on the P&P catalyst performance unit shows clearly the superior catalytic behaviour proposed earlier (see Fig. 2). The ignition temperature for H2S oxidation using a PPH catalyst was found to be below 200°C. H2S conversion yields up to 100% with increasing temperature, forming SO2, which is the dominant sulphurous species between 250°C and 375°C. With further increase of the reaction temperature the reaction proceeds to SO3 with expected thermodynamic limitations as the reduced SO2 conversion at higher temperatures indicates.

The sulphur tolerance of the examined PPH catalysts allows stable long-term operation even at elevated H2S concentrations, avoiding the rapid deactivation observed for other oxidation catalysts. The honeycomb design ensures minimal pressure losses, making it feasible to retrofit the system into existing industrial gas lines without significant requirements for flow or construction adaptations (see Fig. 3). PPH catalysts have been in service for over a decade across more than 30 sulphuric acid and other industrial plants worldwide.

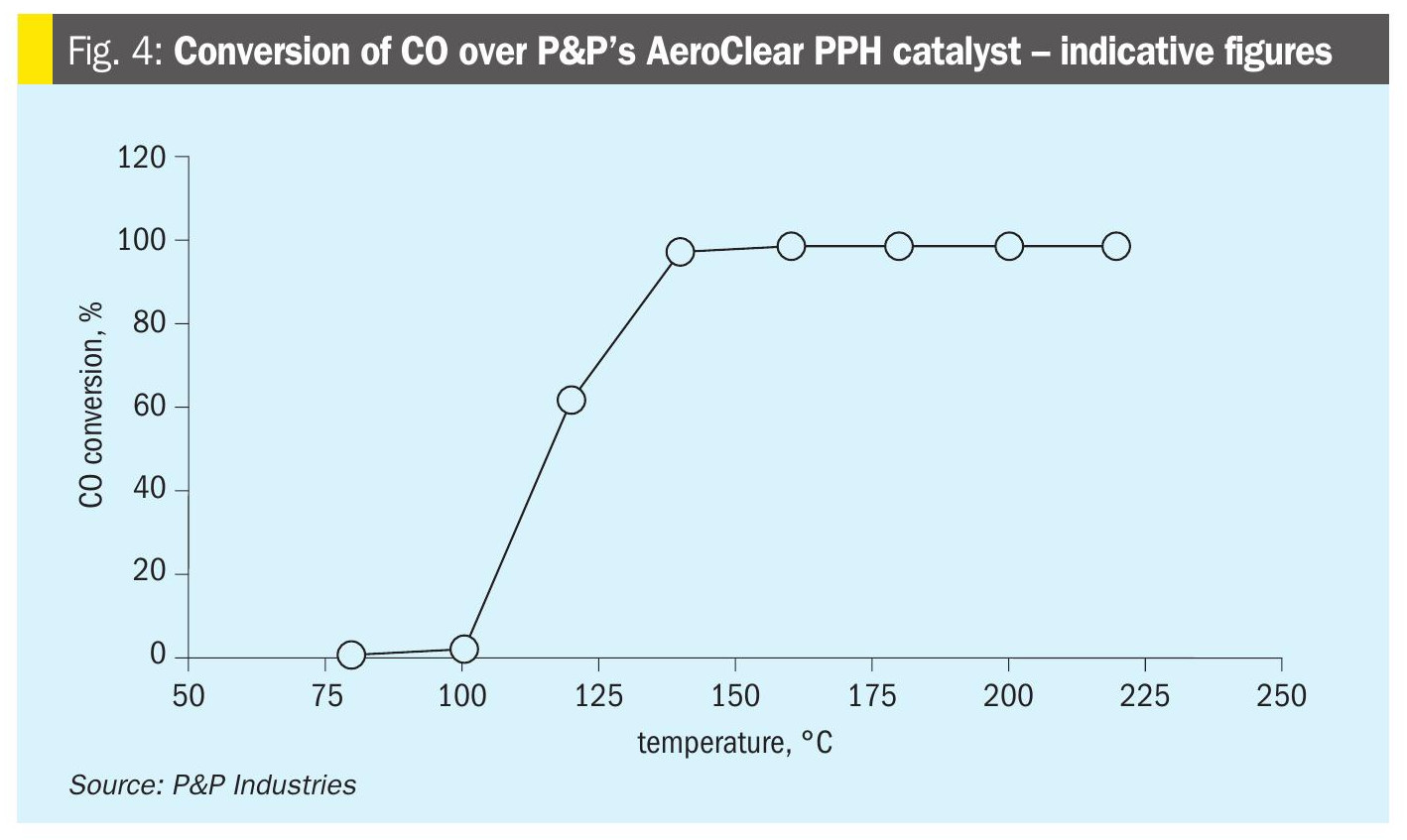

In addition to their superior catalytic performance in oxidising sulphurous species, PPH catalysts also excel in the total oxidation of carbon monoxide (CO) and volatile organic compounds (VOCs) in gas streams. For this challenging task, P&P Industries developed a highly robust total oxidation catalyst named AeroClear. The AeroClear PPH catalyst is characterised by an ignition temperature below 120°C and the capability of yielding 99.9% conversion (Fig. 4). For gas streams containing sulphurous compounds or heavy metals, specialised PPH catalysts from P&P Industries are available. These catalysts offer high resistance to heavy metal poisoning, making them ideally suited for waste-gas treatment in the secondary metallurgical sector. Moreover, two years of continuous operation in a metallurgical plant’s offgas treatment unit, without significant catalyst deactivation (data not shown), underscores the capability of P&P’s PPH catalysts in challenging environments.

The presented study confirms the PPH catalysts to be a highly effective and industrially robust solution for the oxidation of sulphurous compounds (VividOx), CO and VOCs (AeroClear) under demanding conditions. Compared to conventional bulk catalysts, it offers lower pressure drop, higher activity, and exceptional sulphur and poisoning resistance. Thanks to its modular design, thermal stability, and resistance to poisoning, the respective catalysts are highly advisable for demanding industrial environments such as Claus tail gas treatment, fibre production, metallurgical off-gas cleaning, and VOC or CO abatement. The portfolio is completed by P&P’s most recent release, the PrimePurity PPH catalyst, which has been developed for highly selective oxidation of post-SCR ammonia slip to nitrogen.

Overall, the PPH catalyst technology developed by P&P Industries is a versatile, scalable, and energy-efficient solution that couples emission control with economic value creation – validated by customer trust and strong performance across more than 30 operating plants worldwide. Finally, the ability to reclaim platinum at end of life is a further benefit of this innovative technology.