Fertilizer International 529 Nov-Dec 2025

21 November 2025

Flexible fertilizer pastillation

FERTILIZER FINISHING

Flexible fertilizer pastillation

With more than 2,500 systems installed globally, IPCO’s Rotoform technology has become the default solidification solution for a wide range of chemical products – delivering efficiency, quality, and sustainability benefits.

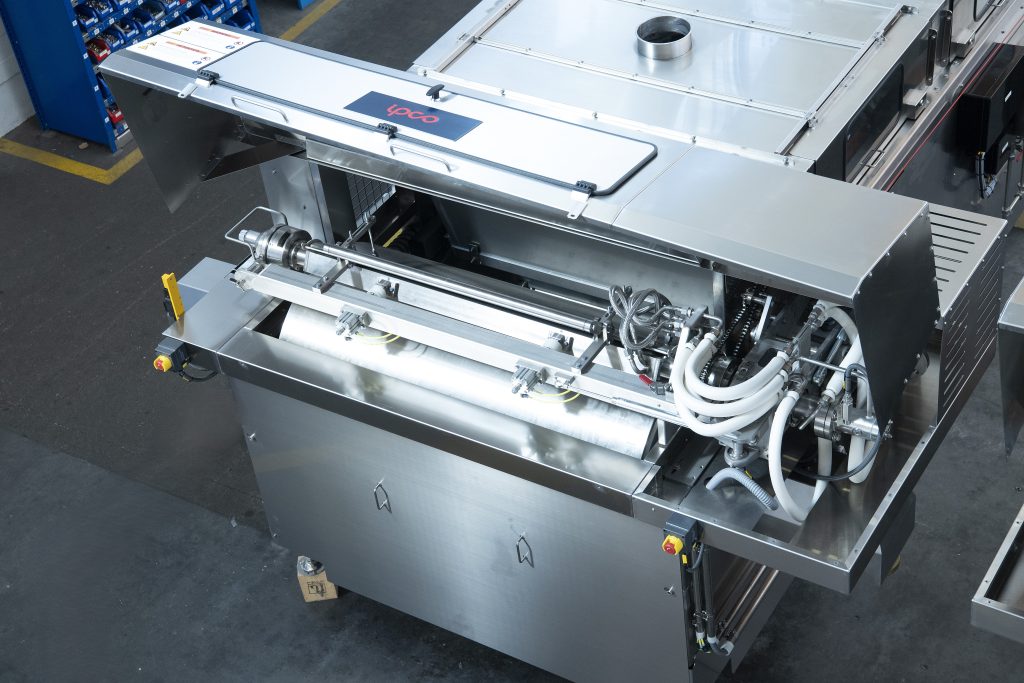

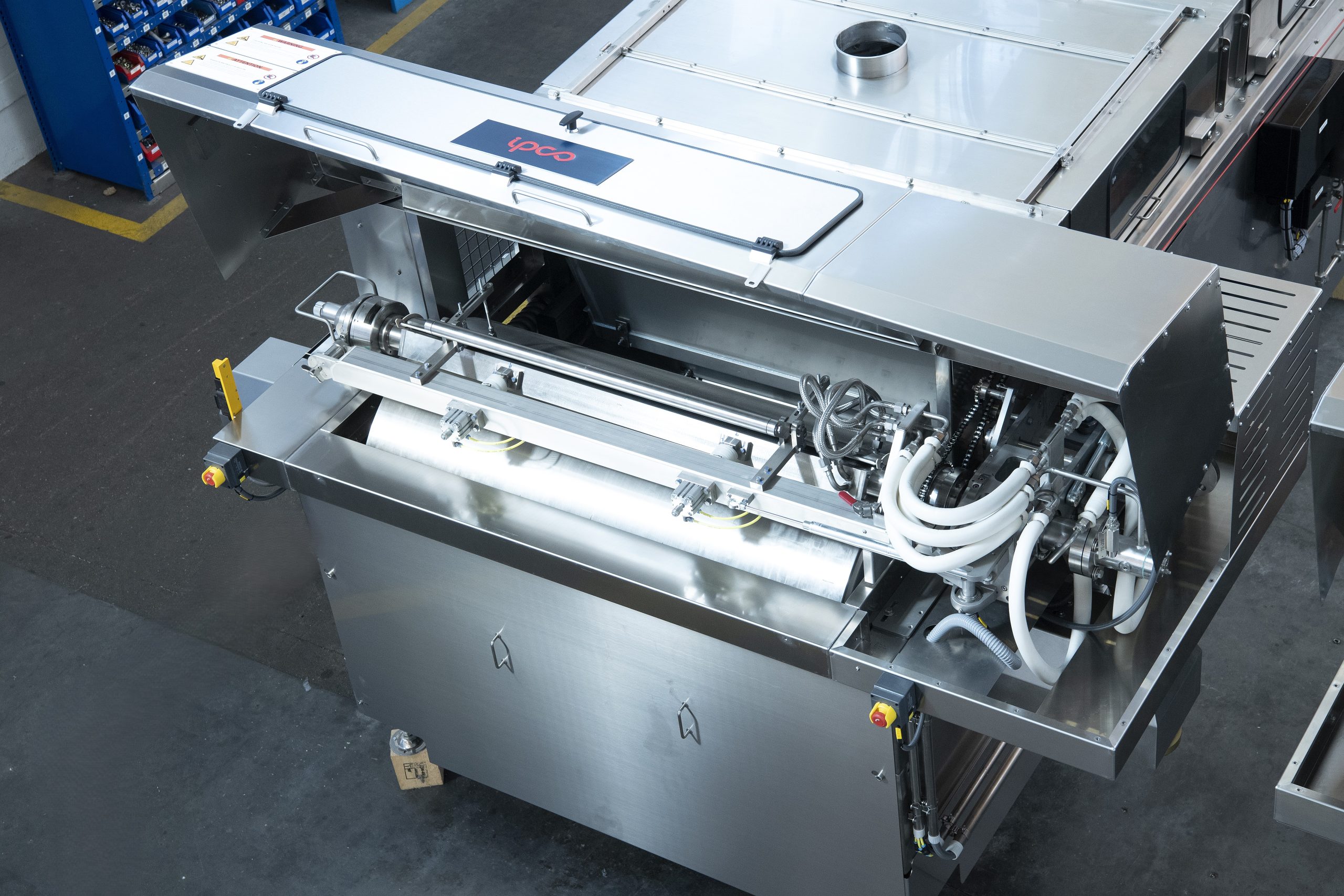

IPCO’s latest Rotoform XG high-capacity pastillation system for fertilizer finishing.

With the world’s population projected to reach around 9.7 billion by 2050, the pressure on agricultural systems to deliver higher yields – despite increasingly degraded soil conditions and finite nutrient resources – continues to mount.

For fertilizer producers, the challenge is twofold: they need to develop multi-nutrient fertilizers that respond to varying soil deficiencies, while doing so within a framework of reduced emissions, improved safety, and enhanced process efficiency. For many, IPCO’s Rotoform granulation system has proved to be the ideal solution.

Originally developed for solidifying the sulphur extracted from oil and gas, Rotoform has gone on to become the default solidification solution for a wide range of chemical products, with more than 2,500 systems installed since its introduction in the early 1980s.

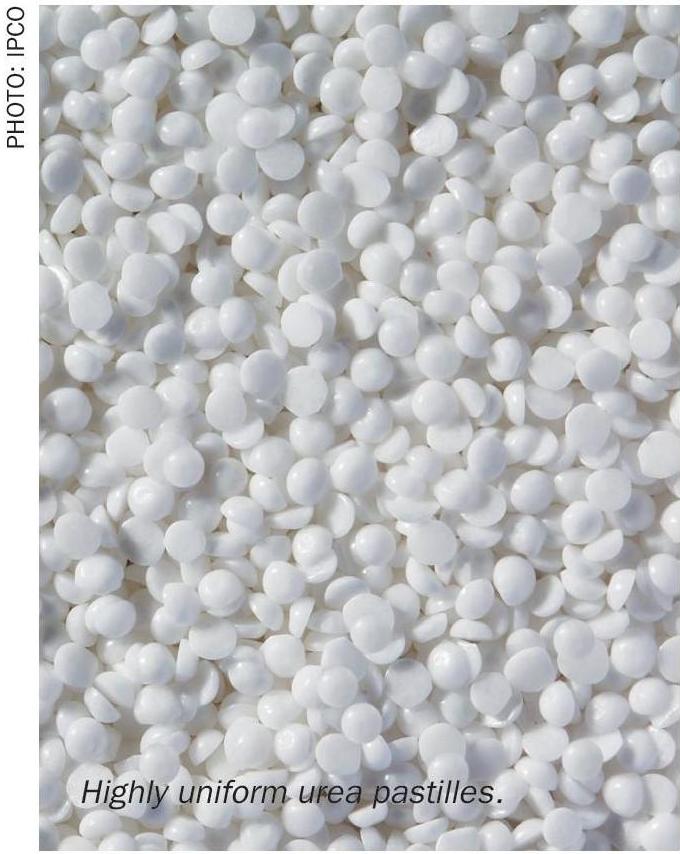

Designed to convert chemical melts into uniform, free-flowing pastilles in a single step, Rotoform combines speed, simplicity, and high product quality with low energy consumption and minimal environmental impact. For the fertilizer industry, it has enabled manufacturers to enhance product quality, reduce emissions, and explore new markets with multi-nutrient and specialty fertilizers.

Controlled, consistent pastillation

The system is based on a simple yet highly controlled process. A liquid fertilizer melt is deposited onto a continuously running stainless steel belt in the form of uniformly sized droplets. As these droplets travel down the belt, cooling water sprayed onto the underside extracts heat, converting them into solid pastilles with high mechanical strength and consistent shape.

One of the key environmental advantages of this process is the separation between cooling water and product: there’s no direct contact, eliminating the risk of cross-contamination and minimising water usage. In addition, the Rotoform system generates virtually no dust or off-gassing, ensuring a safe, clean working environment with very low emissions.

Rotoform technology offers significant advantages over traditional prilling or granulation methods:

• Consistent particle size: Adjustable between 1–5 mm

• High crushing strength: Suitable for both agricultural and technical-grade products

• Low emissions: Negligible dust and vapour generation

• Low power consumption: Efficient use of energy and cooling water

• Minimal waste: No need for crushing, screening, or recycling

These benefits make Rotoform an ideal solution for new installations, plant revamps, or de-bottlenecking projects. With its compact footprint and modular scalability, the system can be integrated alongside existing facilities with minimal disruption.

High-capacity pastillation with Rotoform XG

The Rotoform principle has undergone constant evolution since it was first launched, with the development of a whole range of models designed for specific applications. IPCO recently introduced the Rotoform XG, a high-capacity pastillation system for fertilizer finishing, offering superior handling of low viscosity melts containing solid particles. This new model is an ideal granulation solution for urea products and other suspensions.

The enhancements incorporated into this latest addition to the company’s Rotoform range include significantly easier cleaning and maintenance.

This new Rotoform model – designed for applications such as sulphur-bentonite and urea mixes as well as NPK and other fertilizers – can convert melts containing solid particles into consistent, high quality pastilles from 2-4 mm diameter. The XG is able to process products containing solid additives or contaminant particles up to 200 μm in size. Offering twice the throughput rates of the base Rotoform 4G model, the XG can also process slurries with melt viscosities up to 100 mPas.

Like all Rotoform models, liquid product is delivered to a stator then deposited in drop form, via a rotating perforated outer shell, onto a continuously running steel cooling belt. However, the XG incorporates several innovations including a sliding base frame that allows the Rotoform to be pulled out for easy access, and a floating stator that makes cleaning and maintenance much easier. A bearing system with fewer parts and increased wear resistance further reduces maintenance requirements.

Specialty urea products

IPCO can also supply upstream blending and grinding units for use with Rotoform models. By combining liquid and solid products as suspensions, these enable the production of specialty urea products such as:

• Urea + sulphur

• Urea ammonium sulphate (UAS)

• Urea + potassium

• Urea blended with micronutrients.

These integrated systems can also produce other special fertilizers, including ammonium nitrate, calcium nitrate, magnesium nitrate, and sulphur-bentonite. Precise dosing and mixing capabilities mean that producers can tailor nutrient ratios to specific crop needs or soil deficiencies.

The Rotoform system has additional benefits including quick change overs with minimal downtime, enabling an agile production response to changing market demands. This opens the door to value-added products that can command premium pricing in competitive agricultural markets.

IPCO’s engineering teams can deliver full end-to-end solutions, from upstream mixing and dosing systems to downstream handling, storage, and bagging.

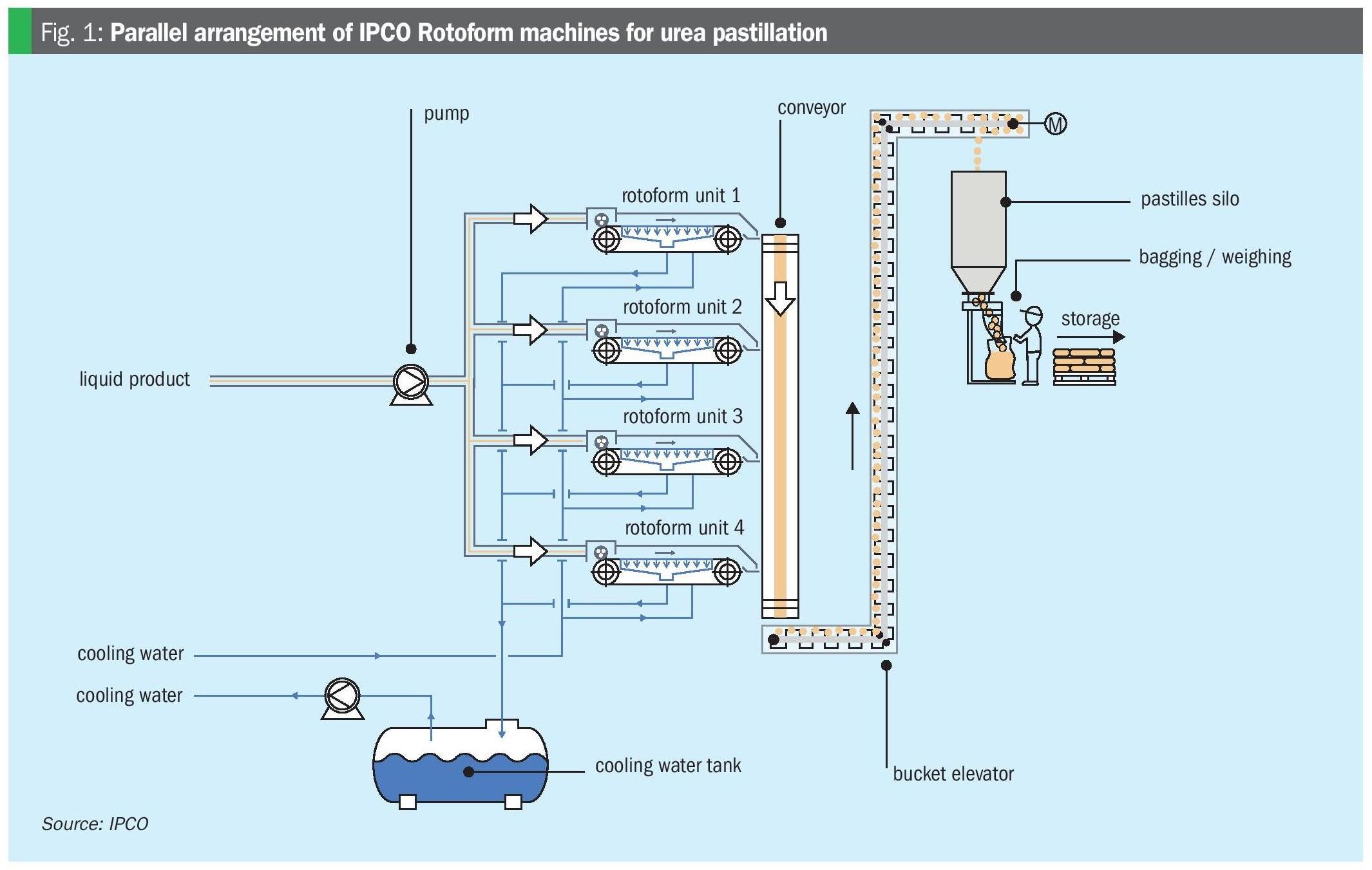

Scalable, modular design for every plant size

Each Rotoform unit offers a throughput capacity of up to 10 tonnes per hour, depending on the product. For larger operations, multiple Rotoform lines can be run in parallel (Figure 1) to deliver capacities exceeding 2,500 tonnes per day. The modular nature of the system means that lines can be activated or shut down based on demand, improving operational efficiency and reducing overheads during low-production cycles.

For companies looking to test new formulations or evaluate the system’s performance under real-world conditions, a complete Rotoform-based production line is available for customer trials at the company’s Productivity Center close to Stuttgart, Germany. Here, customers can run pilot batches using their own materials, validating performance, evaluating emissions, and optimising product quality before scaling to full production.

Being the culmination of more than 90 years’ experience in chemical industry solidification, IPCO’s Rotoform pastillation system provides an efficient, clean, and flexible platform for producing high-quality fertilizers, safely, reliably, and cost-effectively.