Flexible fertilizer pastillation

IPCO’s Rotoform technology has become a popular solidification solution – delivering efficiency, quality & sustainability benefits.

IPCO’s Rotoform technology has become a popular solidification solution – delivering efficiency, quality & sustainability benefits.

IPCO highlights the reasons for converting sulphur into a solid form, and compares two of the technologies most commonly used to achieve this.

IPCO AB has acquired web converting equipment manufacturer New Era Converting Machinery Inc. New Era is a web converting equipment design and manufacturing business, with two facilities in New Jersey, USA, and around 100 employees. Its technology platform of web handling, coating, laminating, and embossing equipment expands IPCO’s presence in key industries, especially in sustainability-driven segments. It also complements IPCO’s double-belt press and film casting solutions.

Mark Brouwer of UreaKnowHow.com reviews the main production options for incorporating sulphur into urea

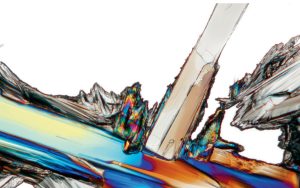

Transporting sulphur as a dry bulk solid can lead to it breaking into small particles which create dust. Over the years, various forming processes have been developed to try and minimise dust formation and produce the strongest, most resilient formed sulphur particles.

Join us at the CRU Sulphur + Sulphuric Acid 2024 Conference and Exhibition in Barcelona, 4-6 November, for a global gathering of the sulphur and sulphuric acid community. Meet leading market and technology experts and producers, network, share knowledge, and learn about market trends and the latest developments in operations, process technology and equipment.

IPCO has expanded its Rotoform range with the high yield XG model for granulation of suspensions. Designed for applications such as sulphur bentonite and urea mixes as well as NPK and other fertilizers, this new Rotoform model can convert solid-containing product melts into consistent, high quality pastilles from 2-4 mm diameter.

Specialty fertilizer products represent a small volume, high value segment of the overall fertilizer market that’s been growing at around four percent per annum in recent years. Economic, environmental, regulatory and agronomic imperatives are driving up their adoption – and an overall shift from volume to value in the fertilizer market.

Mark Brouwer and Jo Eijkenboom of ureaknowhow.com examine the major shifts in global urea production. They also discuss the future of the urea industry and, in particular, how the sector is being affected by the increasing focus on low-carbon ammonia production.

A report on CRU’s annual Sulphur + Sulphuric Acid conference, held in New Orleans, USA, 6-8 November 2023.