Fertilizer International 528 Sep-Oct 2025

11 September 2025

FertigHy – decarbonising fertilizer production at scale

FERTILIZER TECHNOLOGY SHOWCASE

FertigHy – decarbonising fertilizer production at scale

FertigHy was founded in 2023 with the aim of developing, building and operating large-scale low-carbon fertilizer plants across Europe. Producing low-carbon fertilizers from renewable and clean electricity within the region, says the company, will promote re-industrialisation, supply security and stable long-term prices, while also contributing to the decarbonisation of the hard-to-abate fertilizer industry.

Introduction

Madrid-headquartered project developer FertigHy has plans to build a series of low-carbon fertilizer plants within the EU.

Each plant will produce half a million tonnes of low-carbon calcium ammonium nitrate (CAN-27) fertilizer per year and have an annual energy demand of around two terawatt hours (TWh). The carbon footprint of these production plants is expected to be 80-90% lower than their conventional natural gas-based equivalents – resulting in a CO2 emissions reduction of up to one million tonnes every year.

Shifting from ‘grey’ to ‘green’

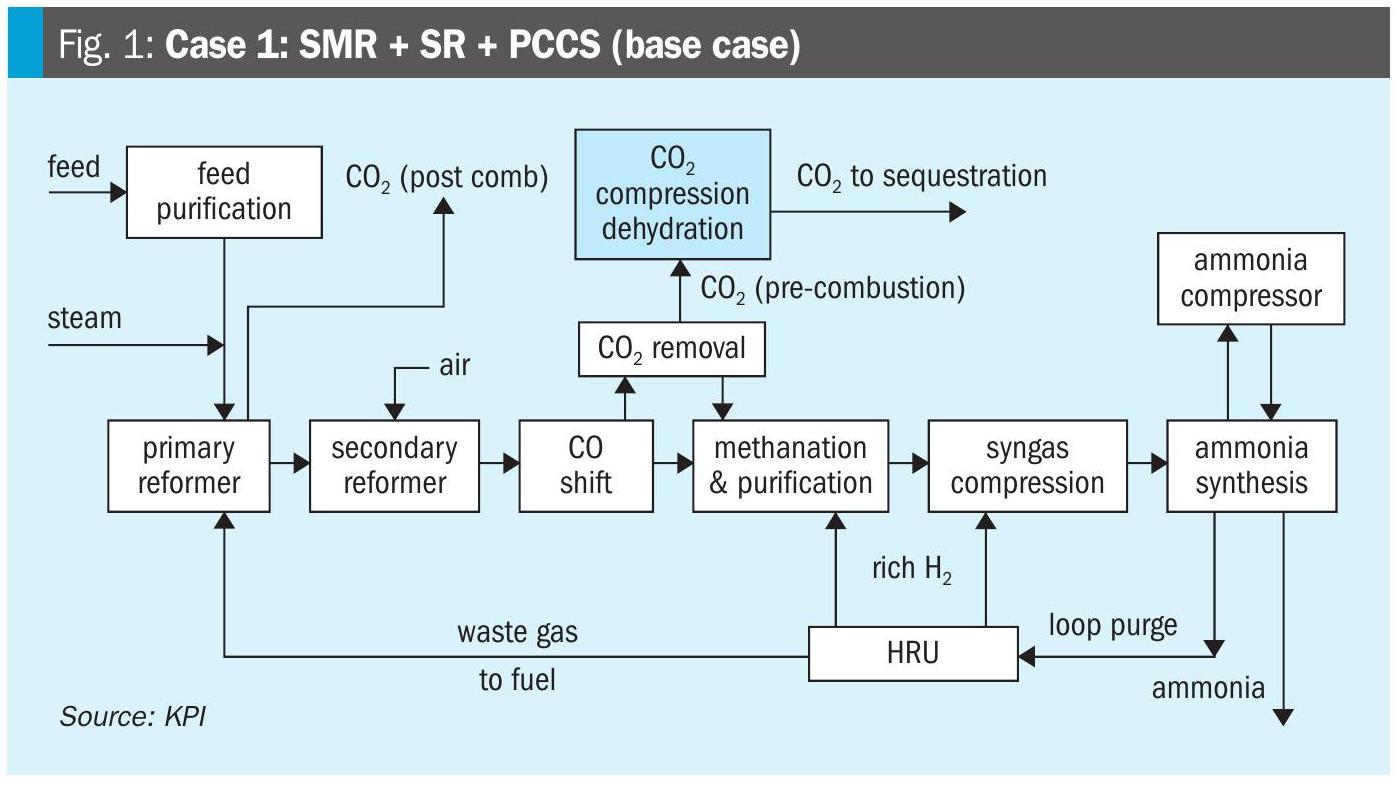

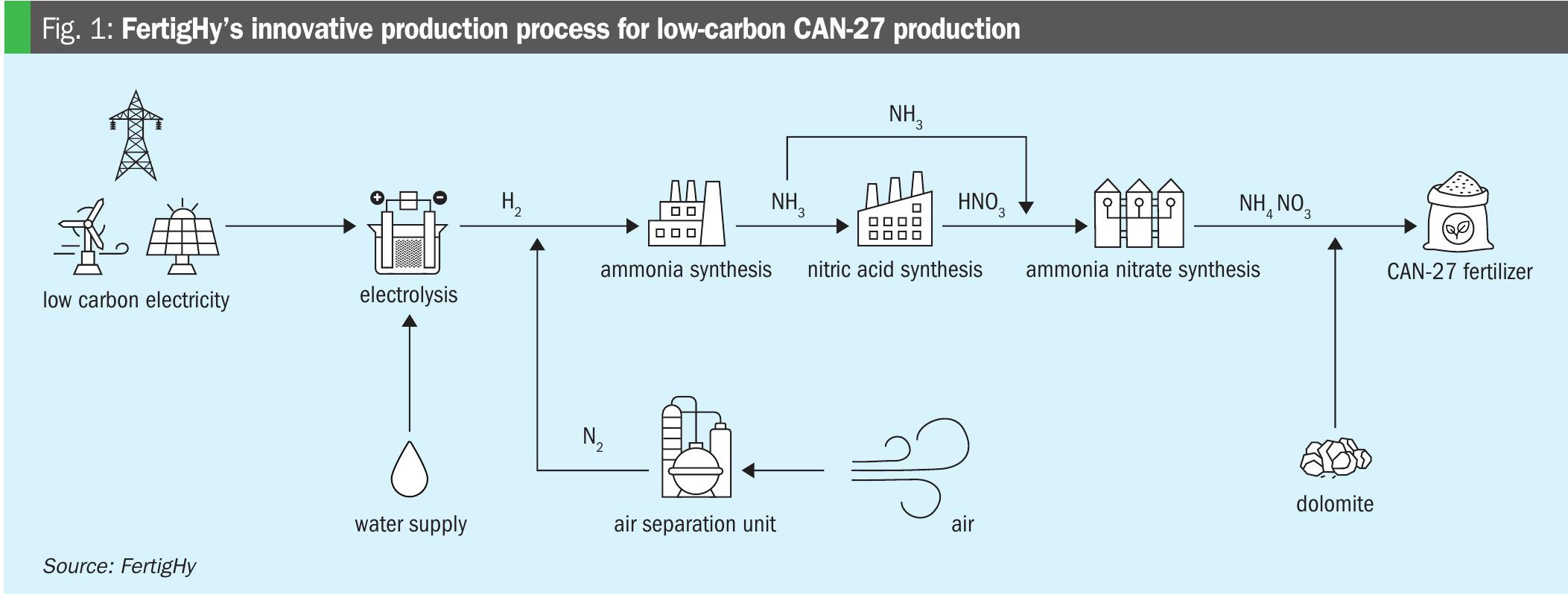

Nitrogen fertilizers rely on ammonia (NH3) as a key ingredient. This is traditionally synthesised from natural gas via the Haber-Bosch process. While Haber-Bosch will remain central to FertigHy’s low-carbon fertilizer production process, the key difference lies in the way hydrogen is produced.

FertigHy will use electrolysers to generate hydrogen instead of the steam methane reforming (SMR) process traditionally used. SMR, being a conventional fossil fuel method, releases significant amounts of CO2. FertigHy’s plants, in contrast, by using low-carbon electricity instead of natural gas, can synthesise decarbonised ammonia and virtually eliminate CO2 emissions.

Units downstream of the electrolysers – for ammonia synthesis, nitric acid, ammonium nitrate and CAN-27 production – utilise well-established and industry-proven technologies with a long history of reliable operation (Figure 1).

Northern France the launching pad

In May 2024, FertigHy selected Languevoisin in the Hauts-de-France region of northern France as the location of its first plant, with construction expected to begin in 2027. The new plant will produce 500,000 t/a of low-carbon fertilizers, a volume corresponding to around 10% of France’s nitrogen fertilizer consumption, and is scheduled to become operational by 2030.

“This project requires an estimated investment of e1.3 billion and will create around 250 direct jobs in the region, demonstrating our commitment to local economic development and job creation,” FertigHy said.

FertigHy’s decision to establish its first low-carbon fertilizer plant in northern France was due to the following compelling reasons:

• The region’s long-standing agricultural base makes it a prime location for fertilizer production.

• France is Europe’s biggest nitrogen fertilizer consumer, with demand of around five million tonnes annually underscoring its market potential.

• The country’s attractiveness for clean hydrogen investment – a result of supportive government policies and subsidies.

• In particular, the development of a support mechanism for low-carbon and renewable hydrogen projects solidifies France’s appeal as a place for FertigHy to invest in and do business.

• Additionally, the country’s robust agricultural sector, coupled with a national roadmap on agricultural and food sovereignty, provides a conducive policy environment for the proposed fertilizer production plant.

• Finally, the chosen site, being strategically positioned in Northern France, offers proximity to key European markets and access to low-carbon baseload electricity.

The unveiling of Languevoisin as the location of FertigHy’s first plant coincided with the announcement of two other major project milestones:

• The completion of a feasibility study and pre-FEED (front-end engineering design) by NEXTCHEM (MAIRE Group). This incorporated NX Stami Green AmmoniaTM and NX Stami Nitric AcidTM technologies, while integrating NEXTCHEM’s hydrogen and electrolyser know-how, to offer a consolidated technical solution.

• The selection of Egis for environmental permit assistance.

FertigHy has now completed these studies, and is preparing for the project’s next phase, which will include the FEED and environmental authorisation.

Six founding shareholders with cross-sector expertise

FertigHy was formed as a consortium of six initial investors with expertise across the whole value chain:

• InnoEnergy, the company’s originator, provides business acceleration services via its European Green Hydrogen Acceleration Centre (EGHAC).

• RIC Energy bring core knowledge in photovoltaic (PV) and electricity markets.

• MAIRE provides experience in the energy transition with competencies in project development, technology, and the engineering procurement and construction (EPC) of ammonia and fertilizer plants.

• Siemens Financial Services brings to the consortium experience in financing large-scale industrial projects.

• InVivo offers support as a purchaser and distributor of fertilizers to 300,000 farmers, representing more than 160 cooperatives.

• Finally, HEINEKEN is exploring ways it can decarbonise at scale, with FertigHy among the many sustainable agriculture initiatives being piloted.

In November last year, FertigHy successfully secured a fresh injection of capital when all its six shareholders unanimously agreed an equity raise.

“This new round of investment demonstrates the continued commitment of all shareholders to the strategic mission to decarbonize the fertilizer industry and the achievement of important milestones in FertigHy’s first facility in Hauts-de-France after completing the feasibility studies,” FertigHy said.

CAN confers benefits

FertigHy’s decision to produce a low-carbon version of calcium ammonium nitrate (CAN-27) reflects the clear advantages offered by this fertilizer over other nitrogen products such as urea. The benefits of CAN-27 include lower volatilisation risk, its neutral impact on soil pH and rapid crop nutrient uptake. The agronomic advantages of CAN-27 and its better overall efficiency for crop cultivation – coupled with the potential for 100% decarbonisation – align perfectly with FertigHy’s commitment to more sustainable agricultural practices.

Driving decarbonisation

Greenhouse gas emissions (GHGs) from Europe’s agriculture sector are significant, accounting for some 10% of total EU emissions. European farmers apply over 11 million tonnes of nitrogen fertilizers annually, leading to substantial environmental impacts.

The production of nitrogen fertilizers is also a major source of industrial CO2 emissions. Encouragingly, the shift to lower carbon hydrogen and ammonia, as part of efforts to decarbonise this sector, can drastically reduce the carbon footprint of fertilizer production.

Conventional fertilizers contribute significantly to Scope 3 emissions generated by the food value chain. The availability and supply of low carbon fertilizers are therefore vital when it comes to food industry decarbonisation.

Scope 3 emissions typically represent 80-90% of the total emissions generated by food and drink companies. Consequently, many sector-leading companies have committed to ambitious decarbonisation goals, aiming to significantly reduce their GHG emissions in line with global climate targets. FertigHy, by producing and supplying low-carbon fertilizers, can support these emissions reduction efforts, thereby helping food and drink companies meet their sustainability goals, as well as mitigating climate change more broadly.

Europe’s import dependency and competitiveness

Recent geopolitical events, such as the conflict in Ukraine, have amplified concerns around supply chain disruption. The reliance of European nitrogen fertilizer producers on externally sourced natural gas feedstock illustrates the region’s supply vulnerability. The region’s agriculture is also partly dependent on nitrogen fertilizers imported from North Africa and Russia.

FertigHy’s ambition to establish new fertilizer production plants within the EU, by reducing these external dependencies, should enhance Europe’s agricultural resilience and bolster food security. Fertilizer production via water electrolysis – generating low-carbon hydrogen using renewable and clean electricity – reduces dependency on fossil fuels as well as eliminating direct CO2 emissions.

Becoming more self-sufficient in fertilizer production also means less price volatility. Natural gas prices and the scarcity of fertilizer supplies have contributed to food price inflation in recent years by driving up costs. Ensuring a stable supply of fertilizers at predictable prices is therefore of strategic importance for Europe.

“FertigHy, by producing and supplying low-carbon fertilizers, can help food and drink companies meet their sustainability goals, as well as mitigating climate change more broadly.

While low-carbon fertilizers might be more expensive initially, upcoming carbon taxes on traditional natural gas-based fertilizers, under the EU’s Carbon Border Adjustment Mechanism (CBAM), will level the playing field. CBAM is being introduced from 2026 with full implementation by 2034.

CBAM will impose new taxes on fertilizer importers, while the reduction of free allowances under the EU Emissions Trading System (ETS) will increase costs for conventional fertilizer production within Europe. This dual pressure, both from CBAM and reduced ETS allowances, will make the availability to farmers of low-carbon fertilizers produced within Europe even more crucial. This shift to lower carbon production will also be important for the overall competitiveness of Europe’s fertilizer industry.